Anti-spin apparatus and method for cone crusher head

A rotary crusher, crushing machine technology, applied in the field of crusher, cone or rotary crusher, can solve the problems of endangering workers, impact and braking, wear of cover and cylinder liner, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Throughout the following description, specific details are set forth in order to provide a thorough understanding to those skilled in the art. However, well known elements may not have been shown or described in detail to avoid unnecessarily obscuring the disclosure. Accordingly, the description and drawings are to be regarded as illustrative rather than restrictive.

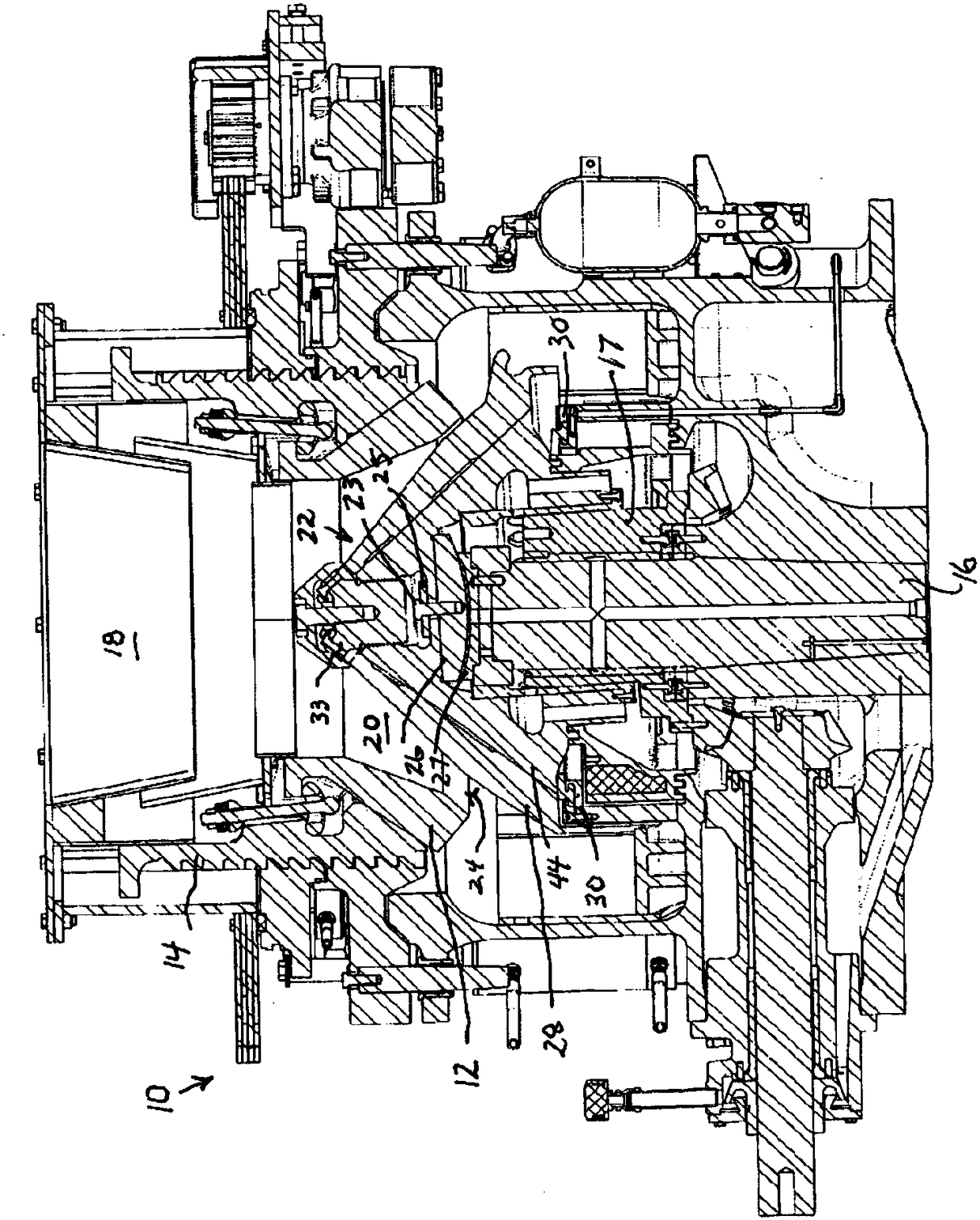

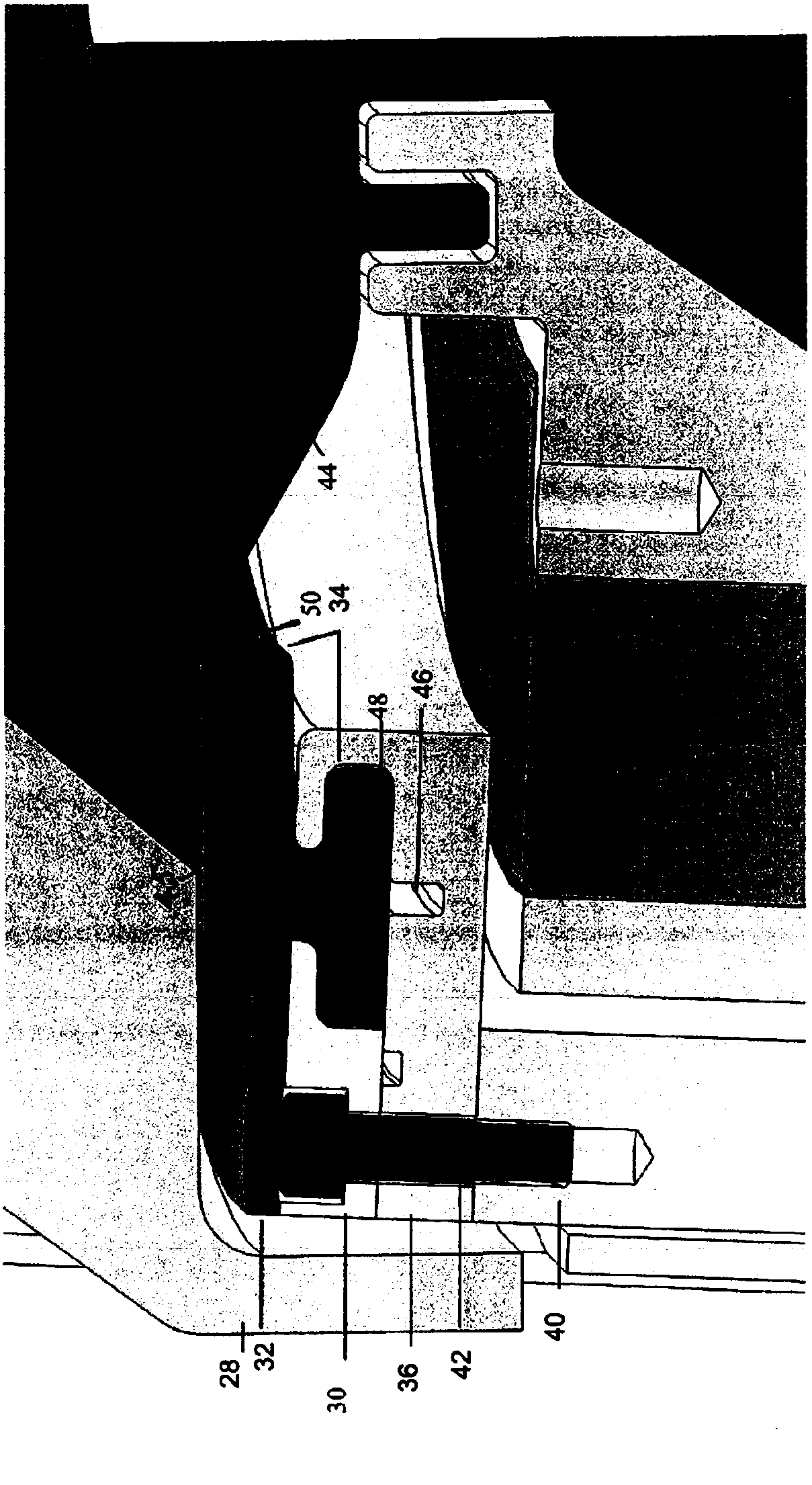

[0020] refer to figure 1 , the cone crusher 10 has a barrel liner 12 mounted in a bowl 14 with a feed opening 18 . The barrel liner 12 has a generally conical inner surface 20 . The crusher head assembly 22 extends upwardly into a space 24 formed by the barrel liner 12 . In operation, the crusher head assembly 22 revolves about the central axis 16 on the head ball 26 . Breaker head assembly 22 is secured to head ball 26 by nut 23 and socket washer 25 . A swivel movement is thereby provided for the head assembly 22 by the head ball 26 , which is freely supported on the socket lining 27 and the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com