LED (Light Emitting Diode) glue dispensing packaging device

A technology of glue sealing and sliding cavity, which is applied to devices and coatings that apply liquid to the surface. The effect of preventing glue dislocation and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

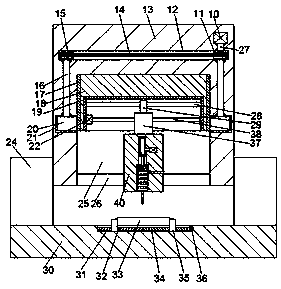

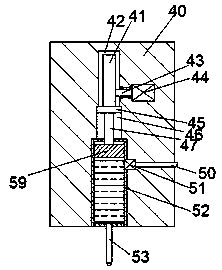

[0014] Such as Figure 1-2 As shown, an LED dispensing packaging device of the present invention includes a main body 13 and an accommodating sliding cavity 25 arranged in the main body 13, and the bottom of the main body 13 is opened to communicate with the accommodating sliding cavity 25 The horizontal sliding chamber 26, the accommodating sliding chamber 25 is provided with a lifting cylinder 18, the outer periphery of the lifting cylinder 18 is set as a helical thread part 17, and the casing 19 with a bottom opening is fixedly arranged in the lifting cylinder 18 , a guide slide bar 28 is fixedly arranged laterally in the casing 19, a horizontal drive screw 38 is arranged below the guide slide bar 28, and the left end of the horizontal drive screw 38 is fixedly arranged on the left side wall of the casing 19. The horizontal drive motor 22 is power-fitted and connected, and the right end of the horizontal drive screw 38 is rotatably connected with the right side wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com