Pneumatic filing machine

A file and pneumatic technology, applied in filing/filing device, filing/filing device, metal processing equipment, etc., can solve the problems of low efficiency, easy arm soreness and fatigue, and frozen shoulder of workers, etc. Achieve the effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

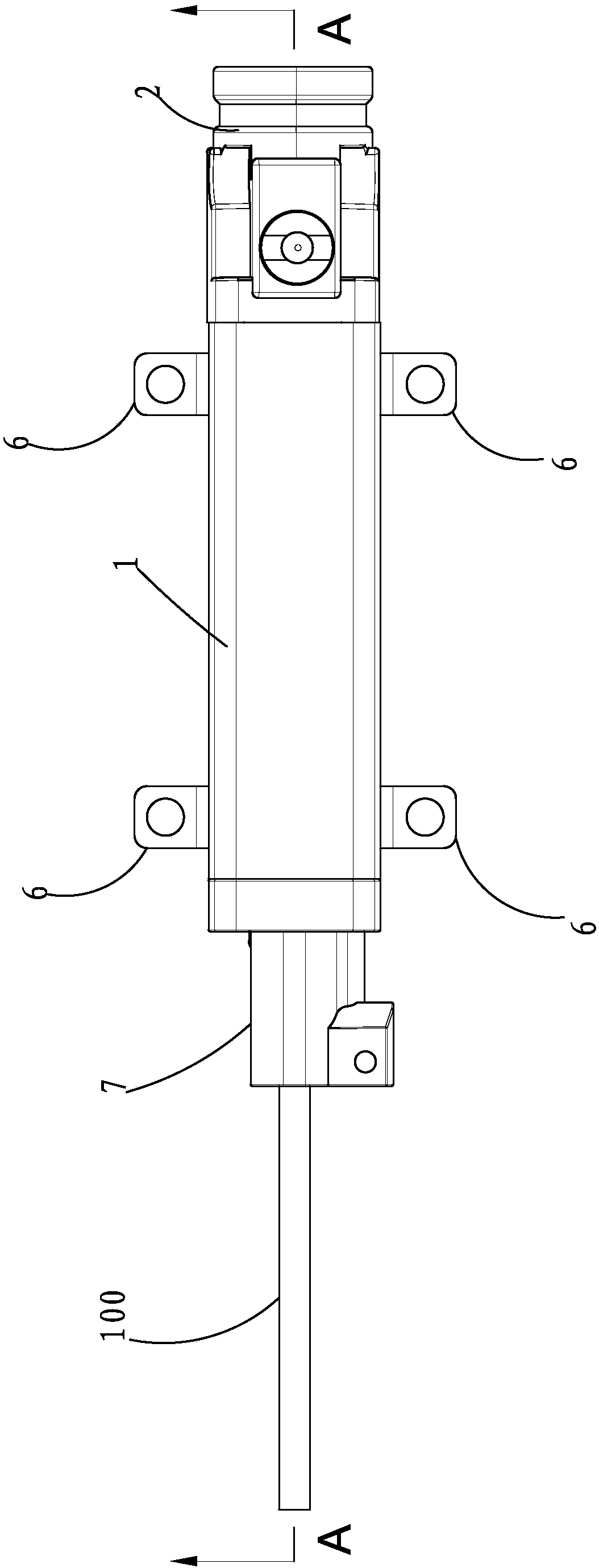

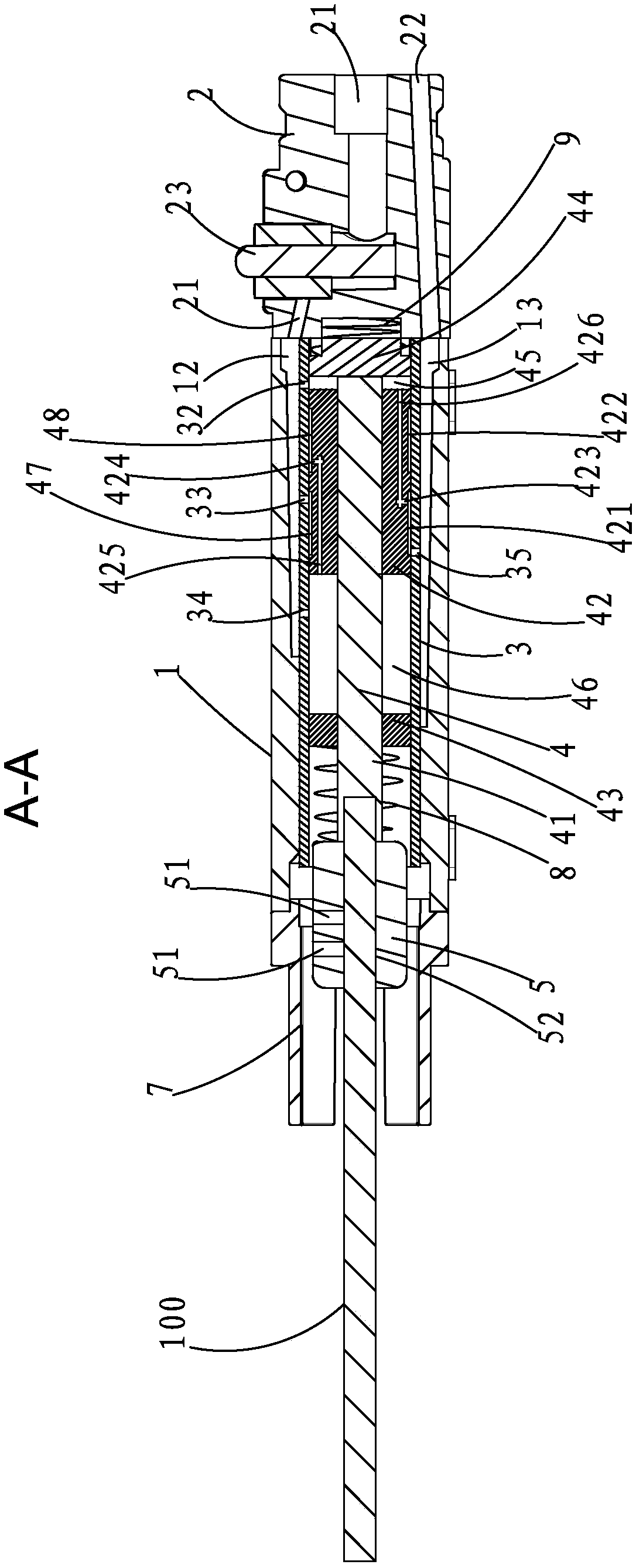

[0026] see Figure 1-7 As shown, a pneumatic file machine of the present invention also includes a main body 1, a valve body 2, a cylinder 3 and a piston rod group 4;

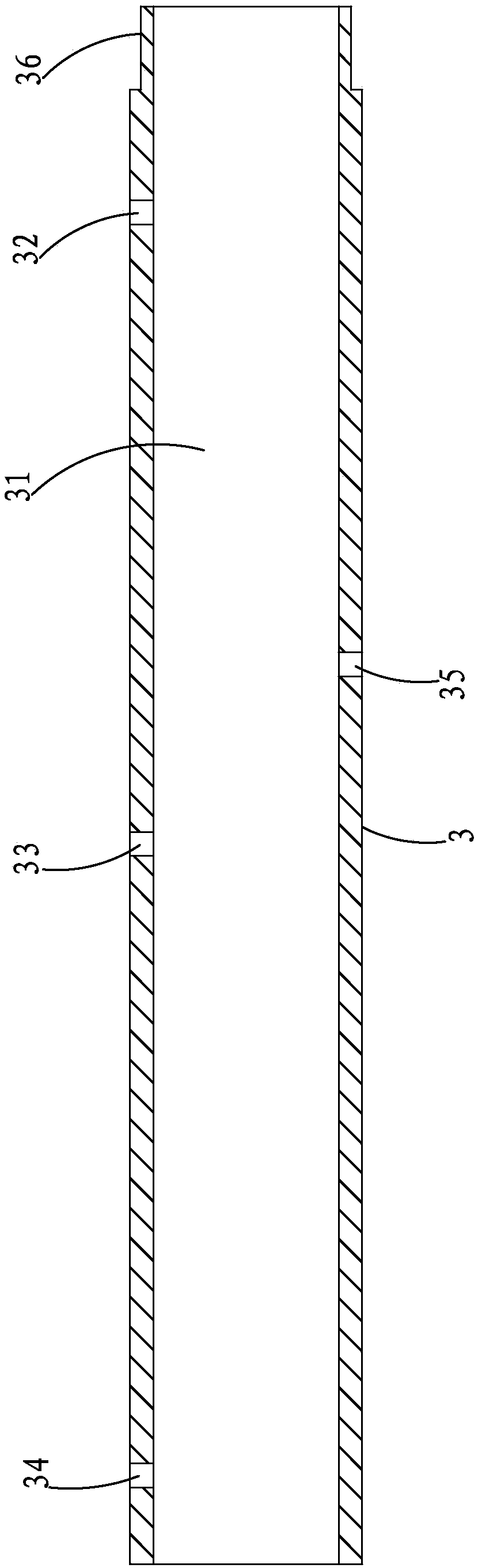

[0027] The piston rod group 4 includes a piston rod 41, a piston 42, a first piston cover 43 and a second piston cover 44; the piston 42 is airtightly slidable on the piston rod 41 left and right; The first piston cover 43 and the second piston cover 44 are fixedly connected to the two ends of the piston rod 41 one by one; the outer surface of the piston 42 is symmetrically provided with a first annular groove 421 and a second annular groove 422, the first A first counterbore 423 is provided at the bottom of an annular groove 421; a second counterbore 424 is provided at the bottom of the second annular groove 422, and a third counterbore 424 is provided on the outer wall of the piston 42 axially from the left end surface of the piston 42. A counterbore 425, a fourth counterbore 426 is opened axially from the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com