A Method for Determining the Optimum Solid Density of Printed Matters

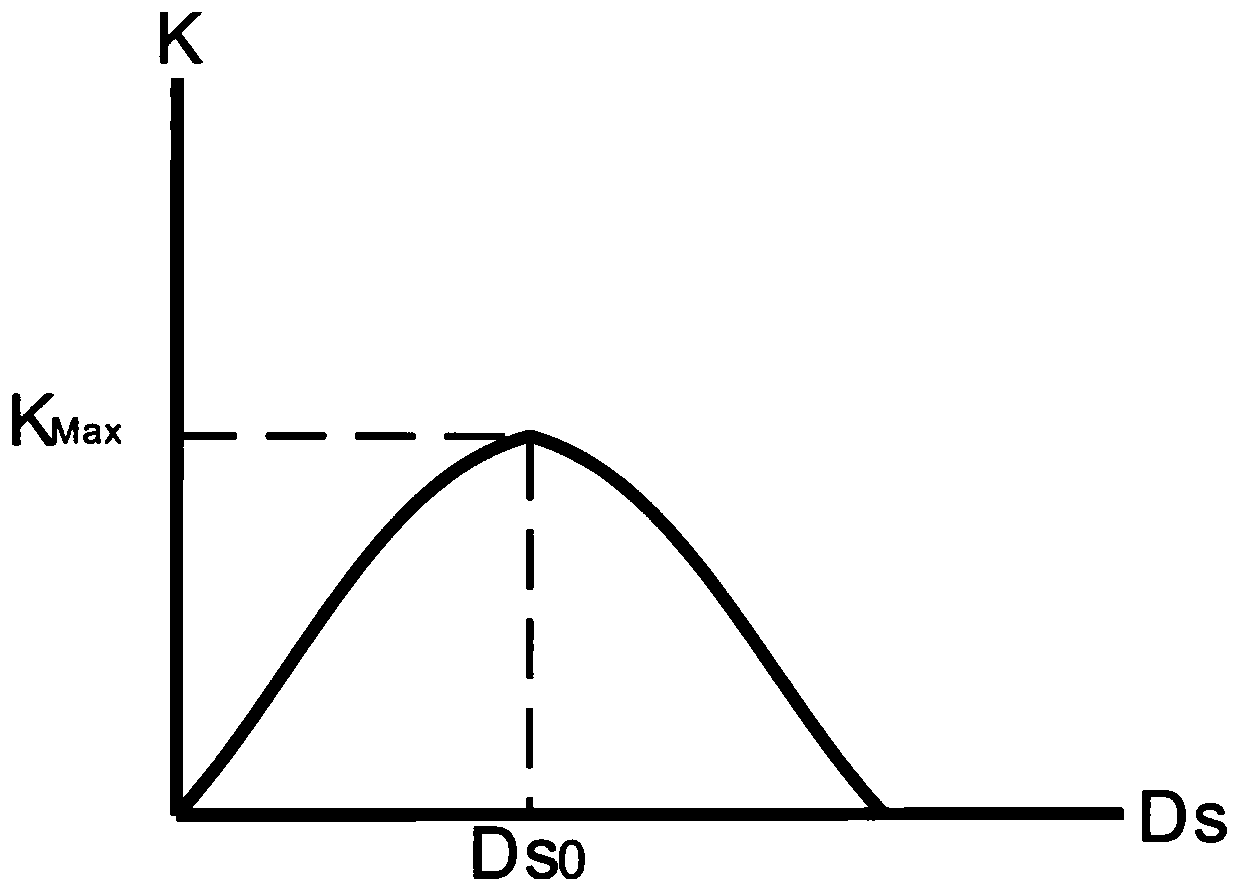

A technology of solid density and determination method, applied in printing, printing devices, etc., can solve the problem of insufficient relative contrast, and achieve the effect of bright colors, fine layers, and suitable dot expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

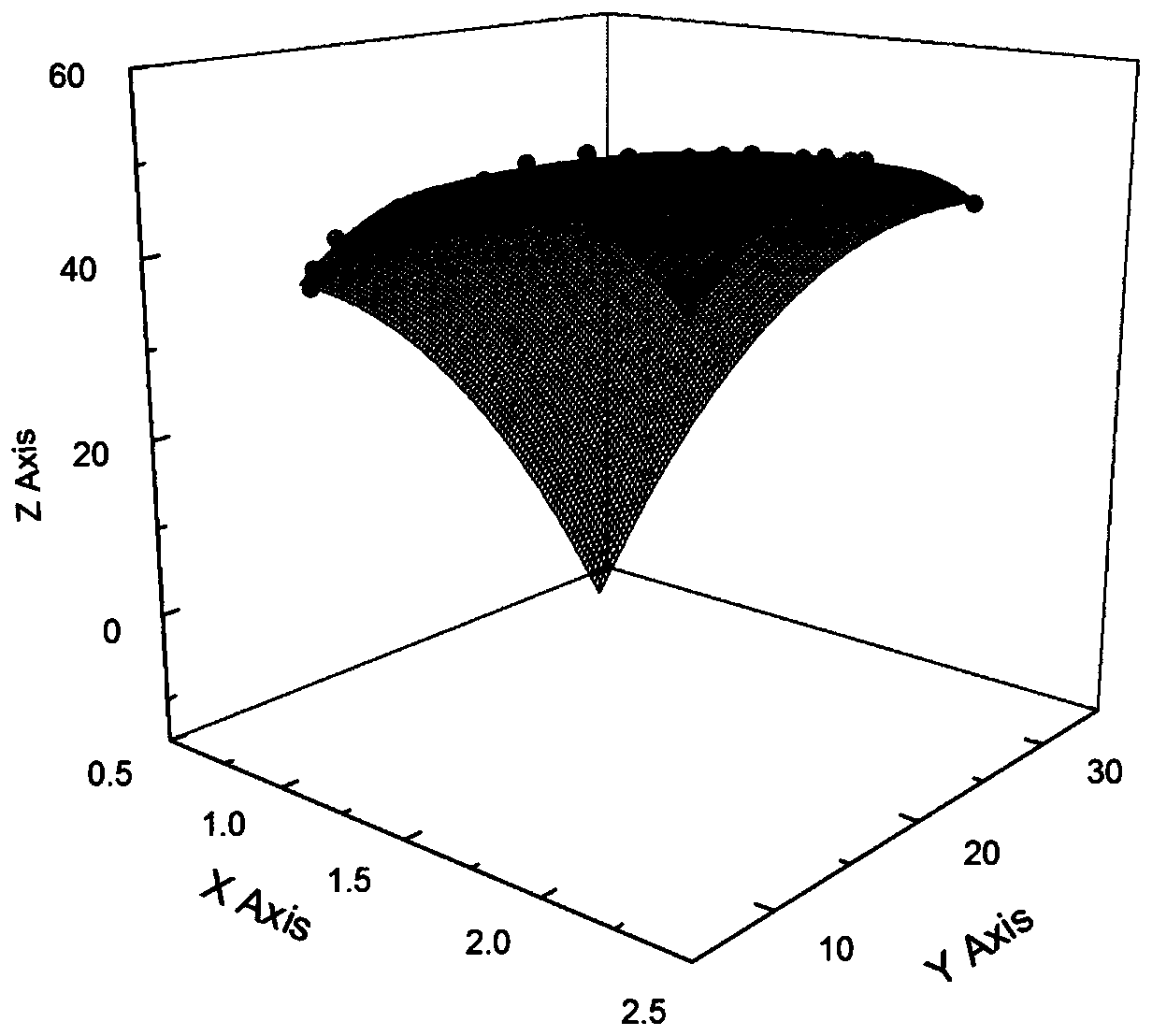

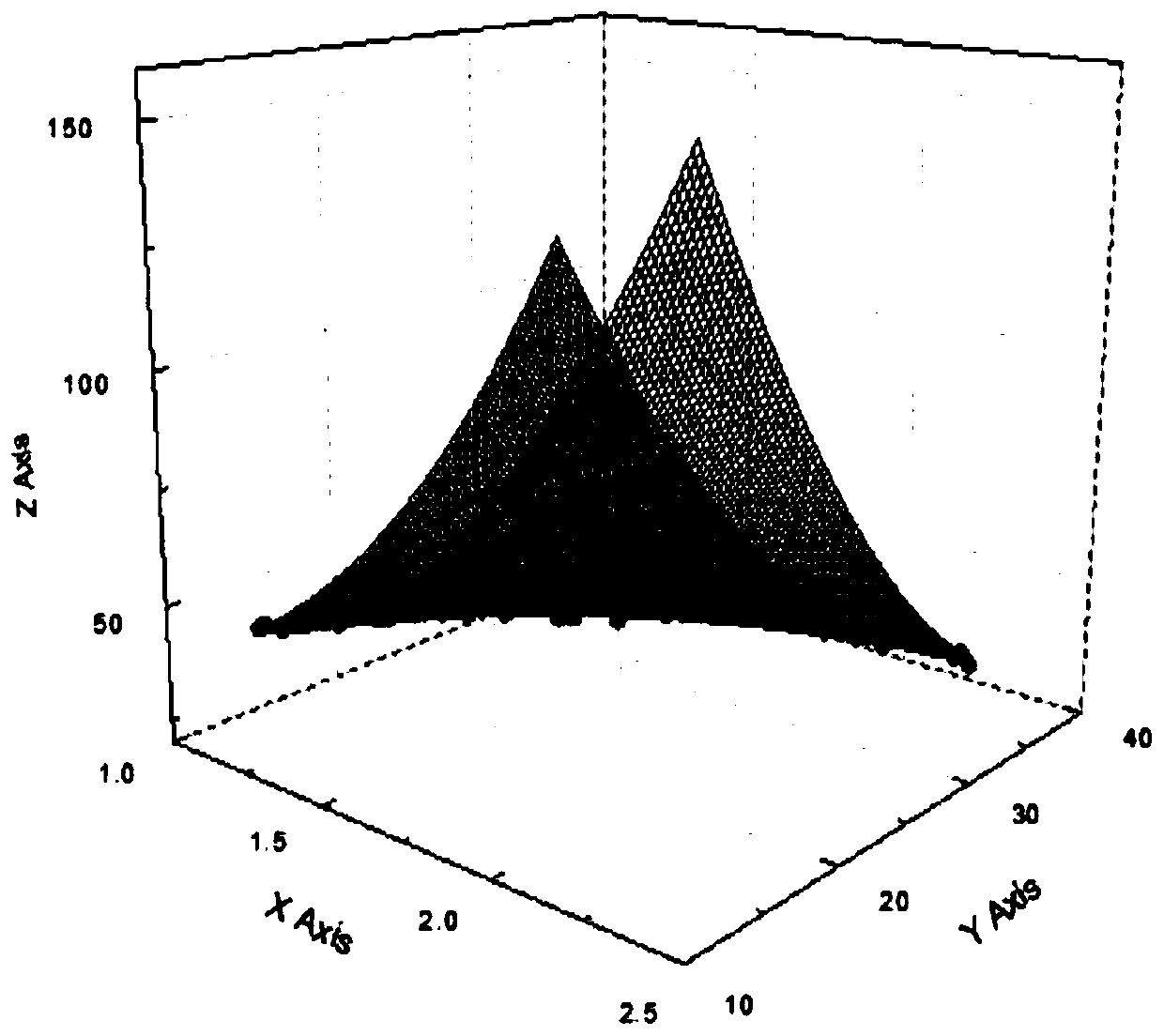

[0050] Now take the determination of the best solid density of magenta M ink and cyan C ink as an example to specifically illustrate the method and operation process of the present invention.

[0051]Step 1: Make a 21-level sample of the magenta M and cyan C color blocks from 0% to 100% with an interval of 5%. Use a Heidelberg offset printing machine to print at a temperature of 20°C and a relative humidity of 38%. The printing color sequence is BK, C, M, Y; the screen line number is 175 lines / inch; the printing pressure is 13 silk; The printing speed is 6000 sheets / hour; the printing material is 157g / m 2 coated paper.

[0052] Step 2: During the whole process from the beginning of printing to the final ink-water balance, take a pass sample every 40 sheets, and take a total of 27 pass samples, and measure the solid density and 75% dots of each sample with a spectrophotometer The density at the area, the actual dot area at 50% of the dot area, and the relative contrast K and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com