Process for rapidly moving equipment of large-mining-height ordered mining working surfaces

A technology with large mining height at the working face, which is applied in the field of mobile relocation, can solve the problems of frequent relocation and reversing of the working face, high pressure of excavation replacement, etc., and achieve the effects of saving labor costs, ensuring reliability, and improving the efficiency of safety removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the description of the drawings and the specific embodiments.

[0064] Preliminary preparation conditions for rapid moving of sequential mining face

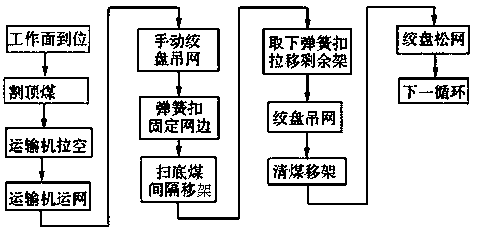

[0065] (1) The pre-dug and withdrawal channel combined with the construction technology of the final mining of the reorganized net

[0066] 1. Cooperate with the final mining process of the reorganized net on the working face to be withdrawn

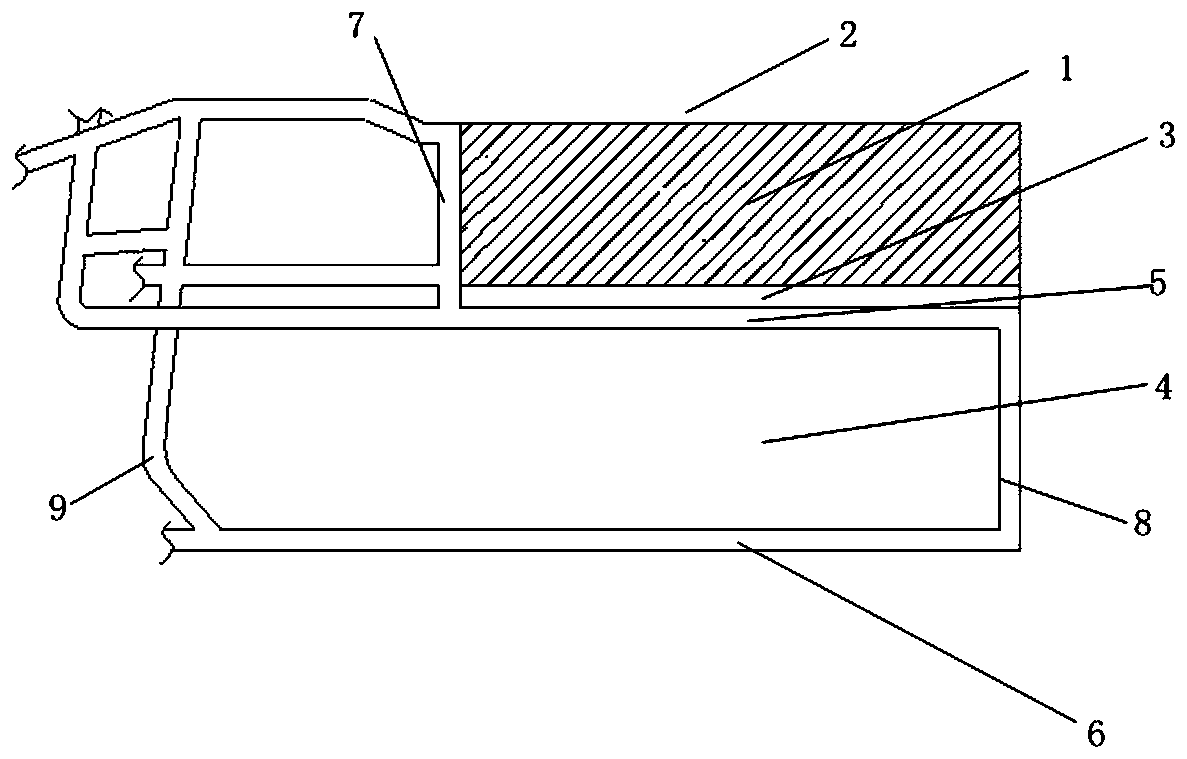

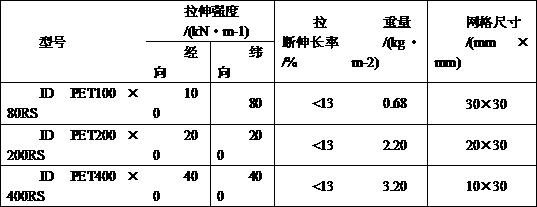

[0067] The coal company takes the working face to be withdrawn as a research pilot, and adopts the mining high-strength polyester fiber flexible net (hereinafter referred to as "flexible net") roofing process for the face finishing work, replacing the traditional metal diamond net roofing process. The mesh is large in area, flexible and light, with high tensile strength, simple process, easy to operate, good flame retardant and antistatic performance, avoids frequent network operation and networking procedures, high s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com