Spring-loaded thrust meter

A spring dynamometer, symmetrical technology, applied in the field of teaching experimental appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

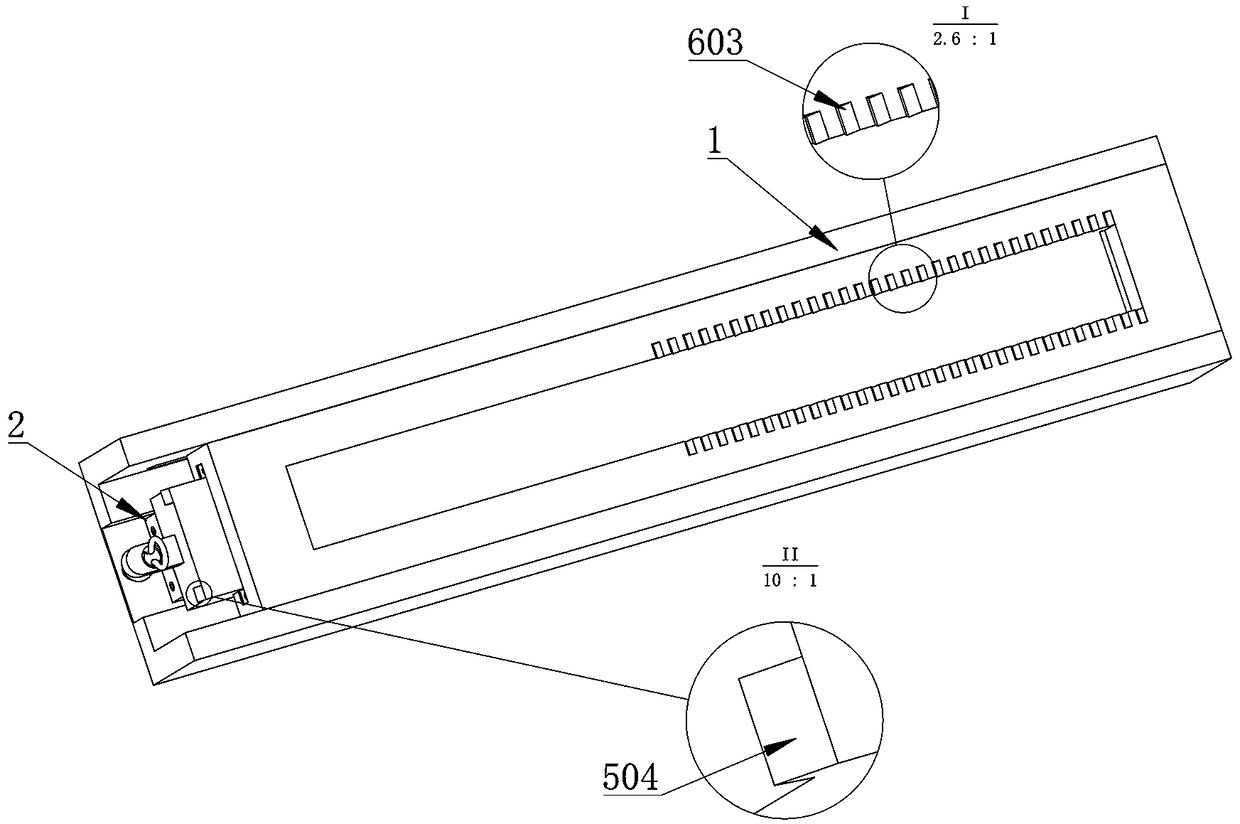

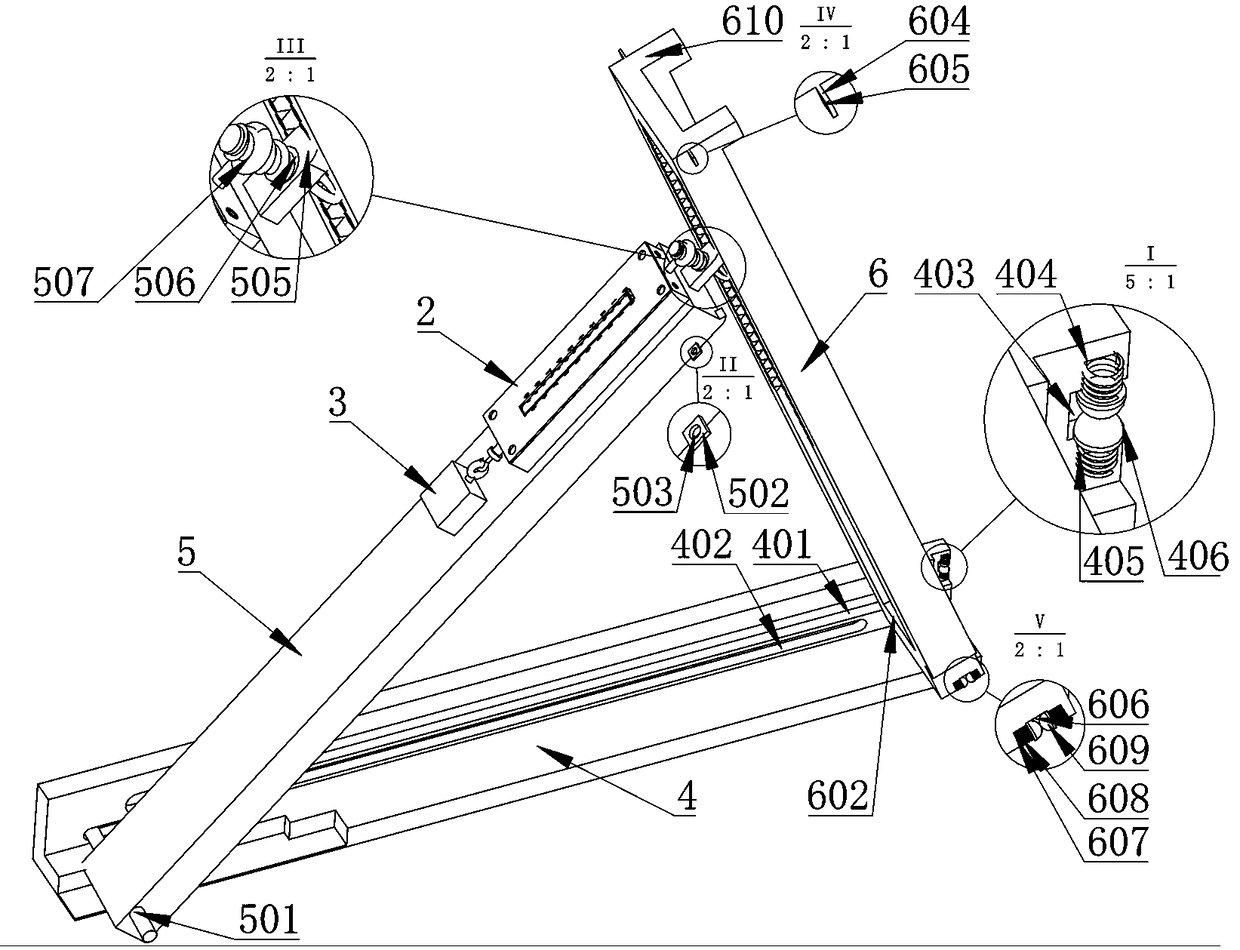

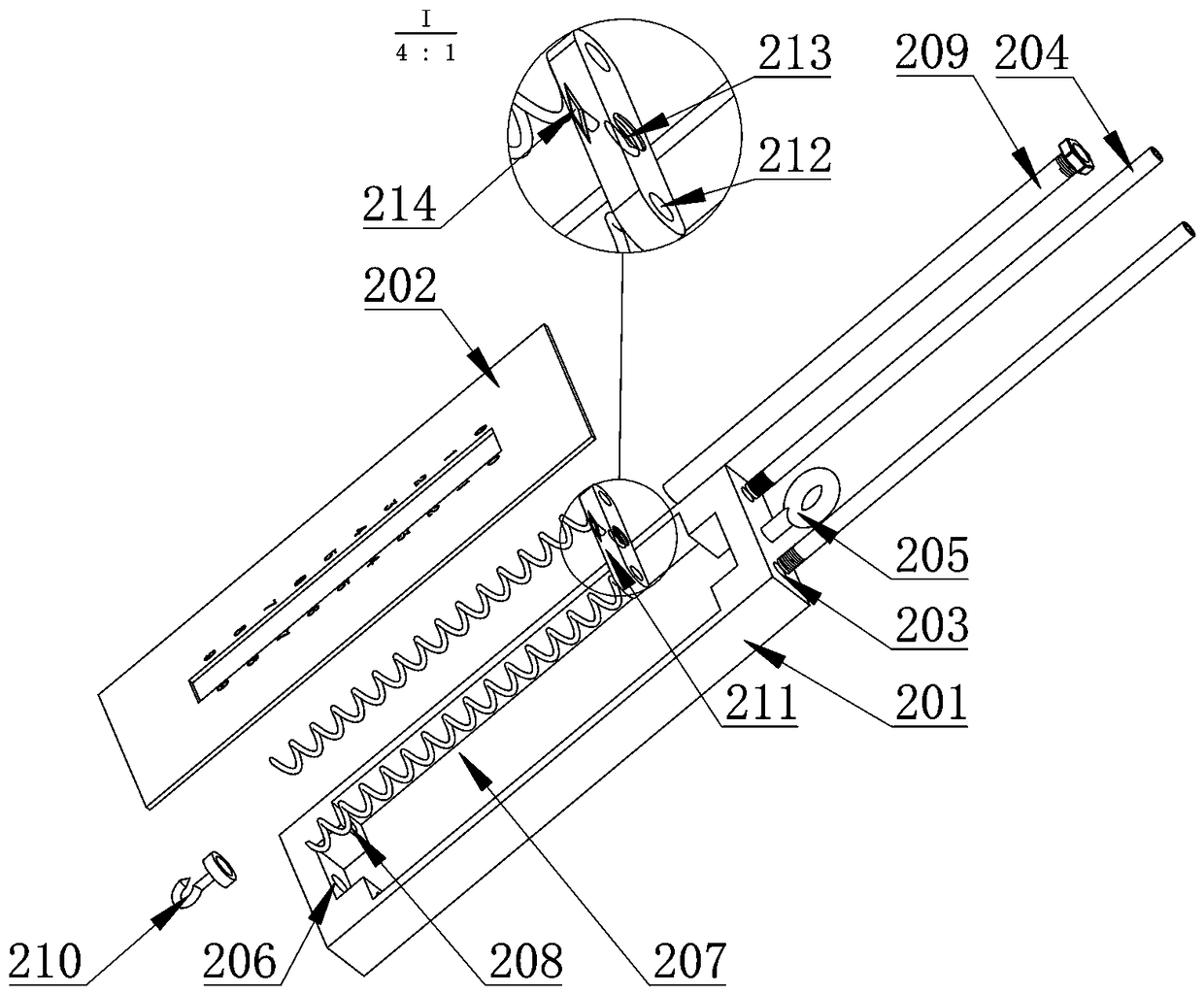

[0017] Specific implementation mode one: combine Figure 1-2As shown, it includes a support platform 1, a spring dynamometer 2 and a weight 3; the support platform 1 includes a main support frame 4, a secondary support frame 5 and an auxiliary support frame 6; the centerline positions on both sides of the main support frame 4 are symmetrical about the length direction A first chute (401) is provided; a second chute 402 is provided directly below the first chute (401); a first rectangular groove 403 is arranged symmetrically with respect to the length direction at one end of the main support frame 4; the first rectangular groove A first circular card slot 404 is arranged symmetrically on the upper and lower sides inside the slot 403; a first spring 405 is arranged in the first circular card slot 404; a first convex button 406 is arranged directly above the first spring 405; the auxiliary support frame 5 The first clamping shaft 501 is arranged symmetrically on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com