Mold loading station and using method thereof

A loading station and mold technology, applied in the field of mold manufacturing, can solve the problems of slow manual operation, high personnel costs, and high requirements for the ability of operating technicians to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the present invention will be described in detail below.

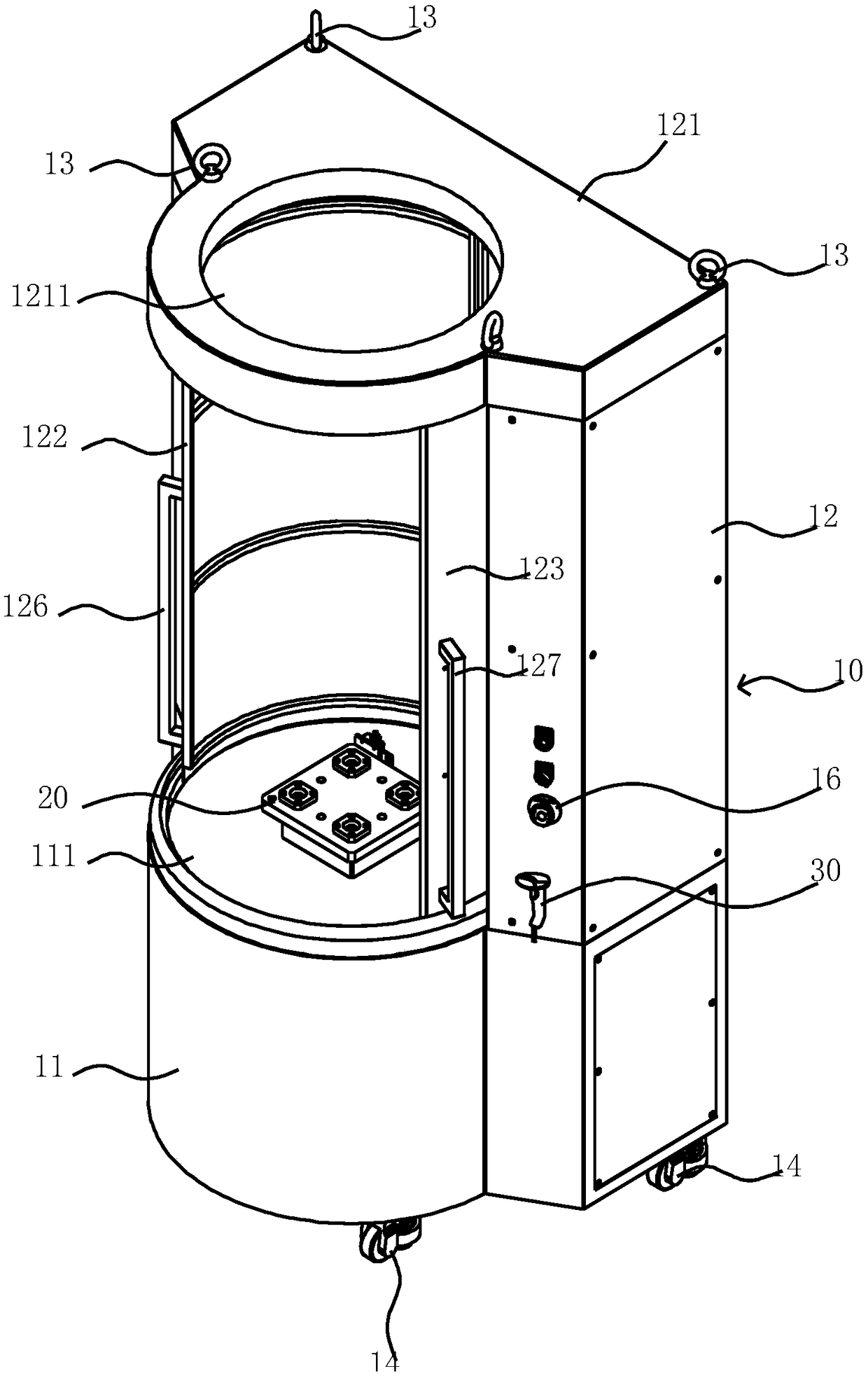

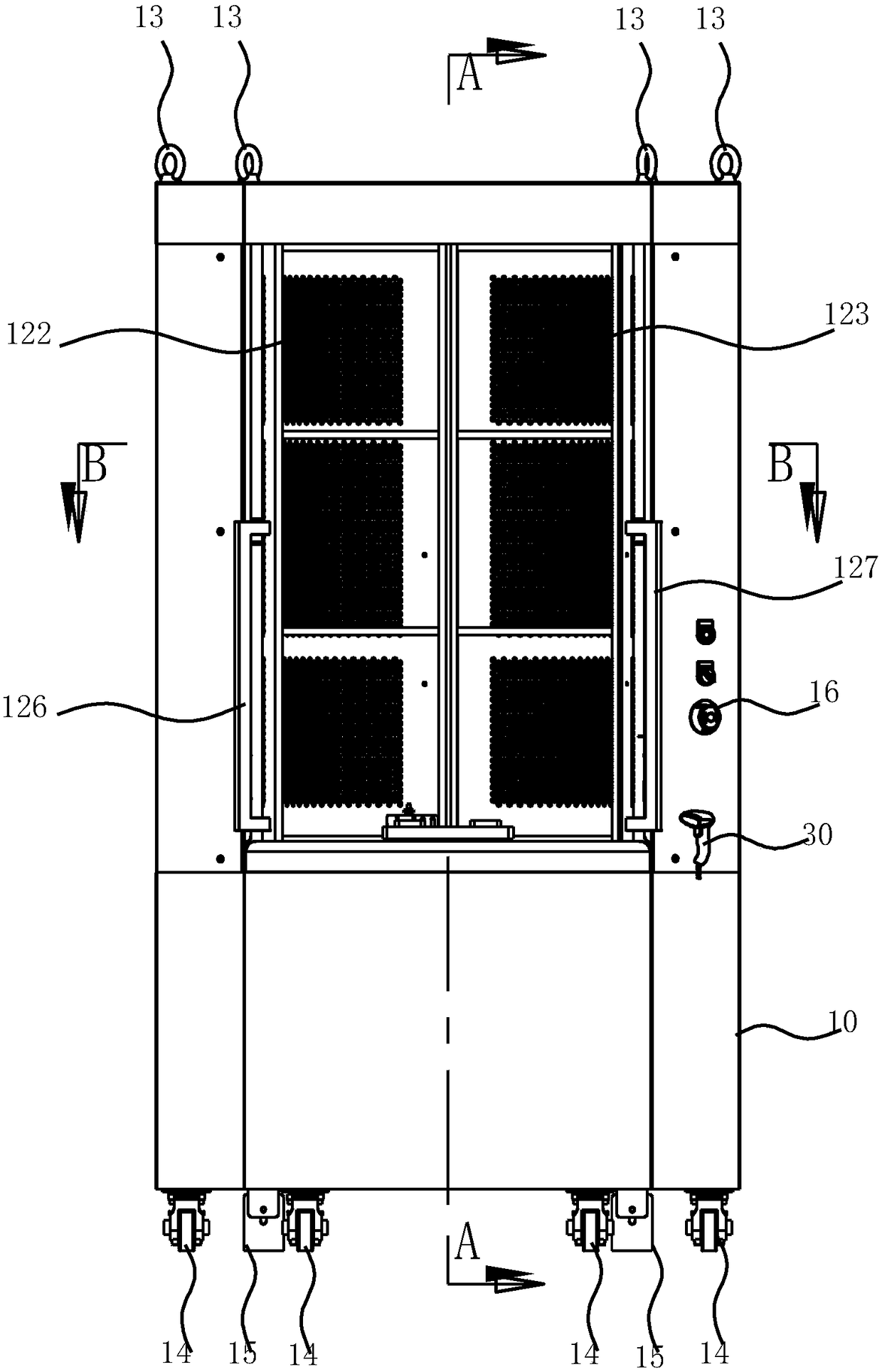

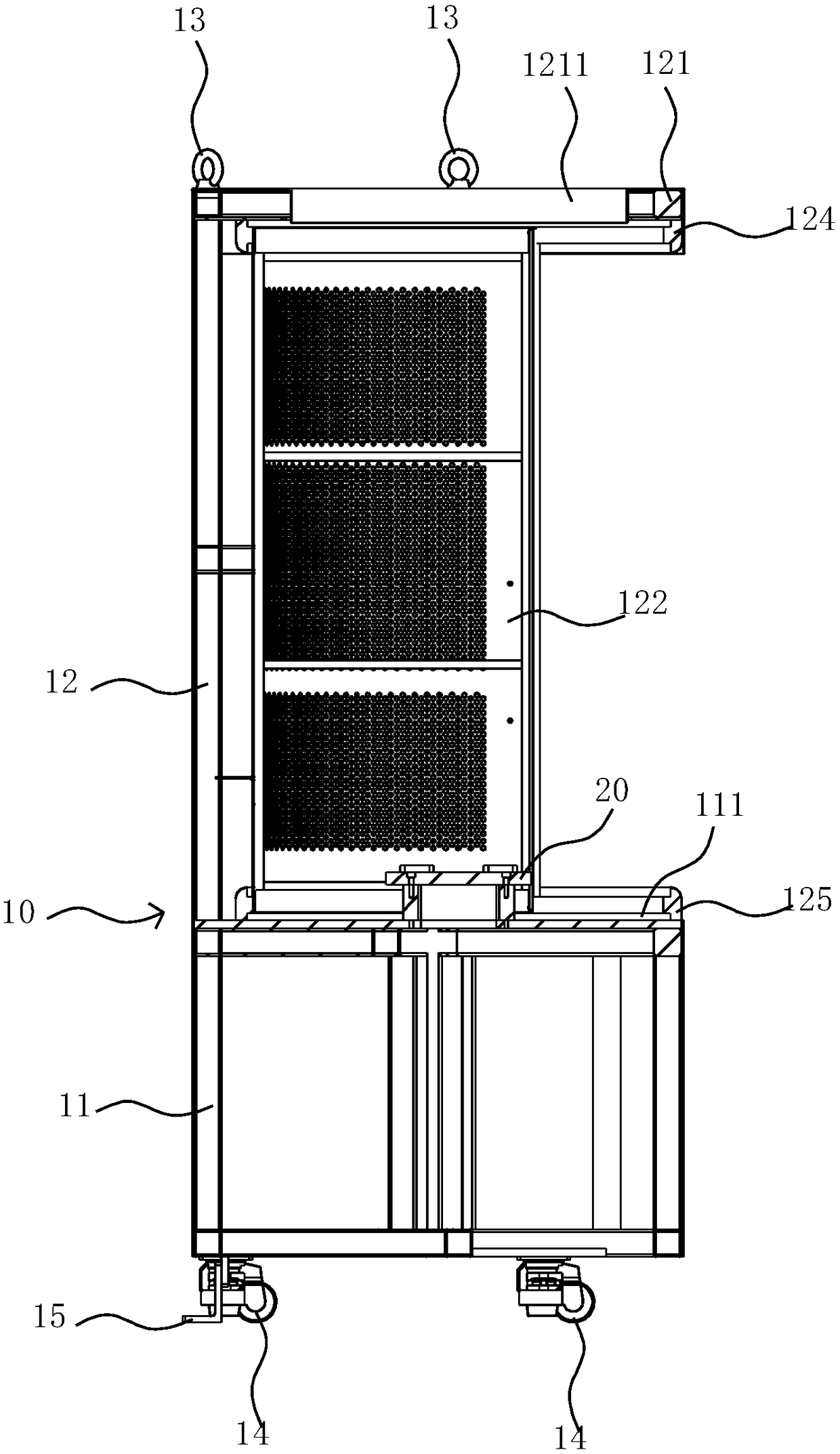

[0053] like Figure 1 to Figure 6 As shown, the mold loading station includes a main frame 10, a loading mechanism 20, a main controller, and a reader-writer 30. The main frame 10 includes a loading cabinet 11 and a loading frame 12. The top of the loading cabinet 11 has a loading platform 111, and the loading frame 12 Installed above the loading chassis 11, and form a loading chamber with the loading platform 111;

[0054] The main controller is installed in the loading chassis 11, the loading mechanism 20 is installed on the loading platform 111, and is electrically connected with the main controller; the reader 30 is arranged on the main body frame 10, and is electrically connected with the main controller.

[0055] Wherein, the top of main frame 10 is provided with suspension ring 13, and suspension ring 13 is a plurality of, and a plurality of suspension rings 13 are distributed on the top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com