Horizontal battery wax sealing equipment

A horizontal battery and equipment technology, applied in the construction of lead-acid batteries, lead-acid batteries, battery pack components, etc., can solve the problems of corrosion of external substances, inability to realize immediate wax sealing, waste, etc., and achieve the goal of preventing sulfuric acid from dripping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] To achieve the above objective, the basic scheme of the present invention is as follows:

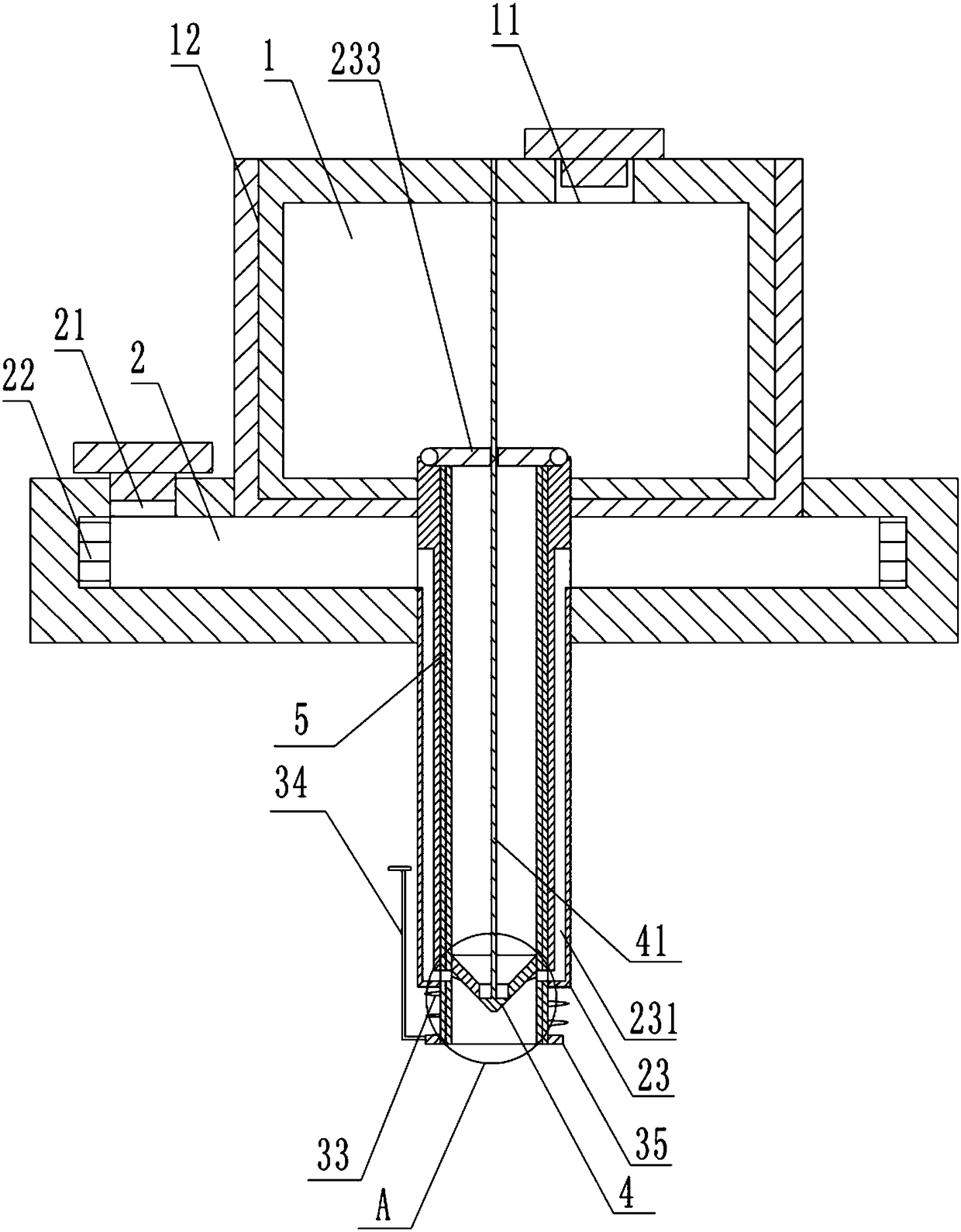

[0030] Such as figure 1 As shown, the horizontal battery wax sealing device includes a device body with a convex cross-section, and the device body is composed of two cylinders, the diameter of the upper cylinder is smaller than the diameter of the lower cylinder. A sulfuric acid chamber 1 and a sulfuric acid port 11 for adding sulfuric acid into the sulfuric acid chamber 1 are arranged in the upper cylinder. The lower cylinder is provided with a wax cavity 2 and a waxing port 21 for adding wax to the wax cavity 2, and both the sulfuric acid port 11 and the waxing port 21 are provided with a cover for sealing.

[0031] An insulating layer 12 for heat insulation is provided in the cavity wall of the sulfuric acid chamber 1; a heating part 22 is provided in the wax chamber 2 and the heating part 22 includes a plurality of electric heating wires.

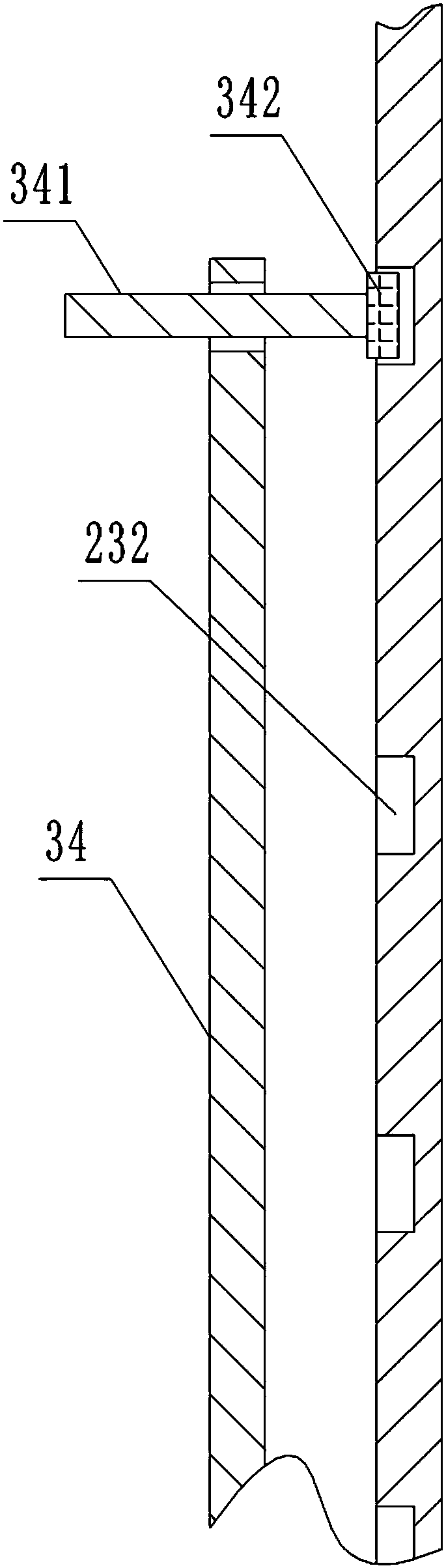

[0032] A wax filling tube 23 is fixed at ...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 lies in Image 6 As shown, it also includes a cooling part 6 which includes a cooling box and a refrigeration pipe located in the cooling box; the cooling box is fixed on the upper surface of the equipment body; the upper end of the push rod 41 extends into the cooling box. It can be further ensured that the push rod 41 can transfer the cold source to the conical cover 4 so that the wax at the conical cover 4 solidifies quickly.

Embodiment 3

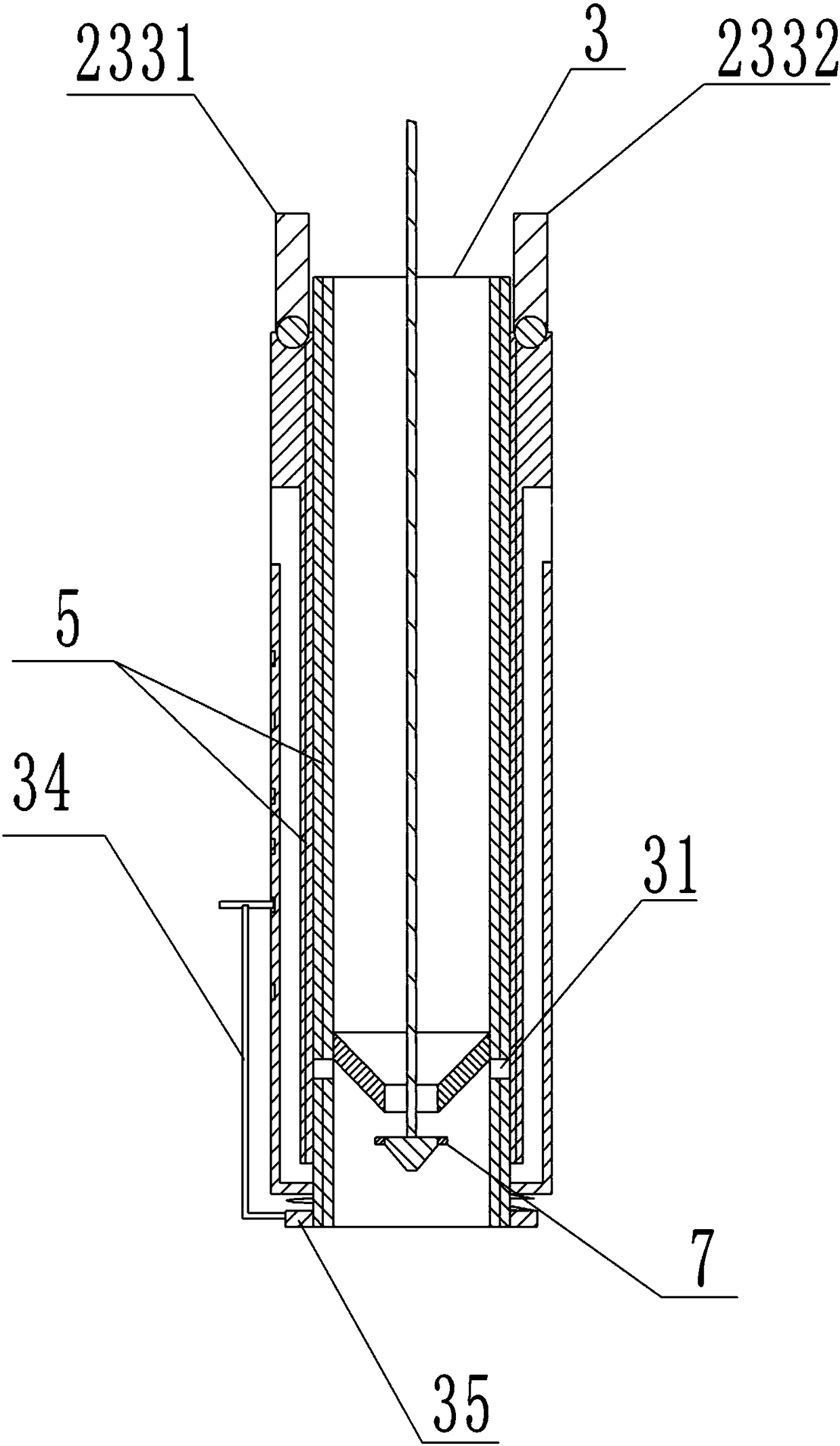

[0045] The difference between this embodiment and embodiment 1 is that: the lower part of the acid discharge channel 321 is provided with an inverted cone-shaped cover 4; the upper surface edge of the cone-shaped cover 4 is fixed with a ring of convex edges 7 (such as Figure 7 (Shown), the diameter of the annular flange 7 is greater than the diameter of the cylindrical channel 3212.

[0046] An L-shaped push rod 71 is fixed on the upper surface of the conical cover 4; a strip-shaped sliding port is provided on the side wall of the acid filling tube 3, and the upper end of the L-shaped push rod 71 passes through the strip-shaped sliding port and is fixedly connected to the wax filling pipe 23; The lower end of the acid filling pipe 3 extends out of the wax filling pipe 23, and a return spring 33 is provided between the lower end of the acid filling pipe 3 and the wax outlet pipe; the acid filling pipe 3 and the wax filling pipe 23 are provided with partitions in the pipe walls. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com