Horizontal battery sealing wax method

A horizontal battery and wax filling technology, applied in lead-acid batteries, battery pack components, lead-acid battery construction, etc., can solve problems such as safety accidents, external material corrosion, waste and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In order to achieve the above object, the basic scheme of the present invention is as follows:

[0036] The horizontal battery sealing wax method comprises the steps:

[0037] Step 1, material preparation: dilute sulfuric acid and wax;

[0038] Step 2, melting wax: heating the wax in step 1 to form wax in a fluid state, and then stirring continuously;

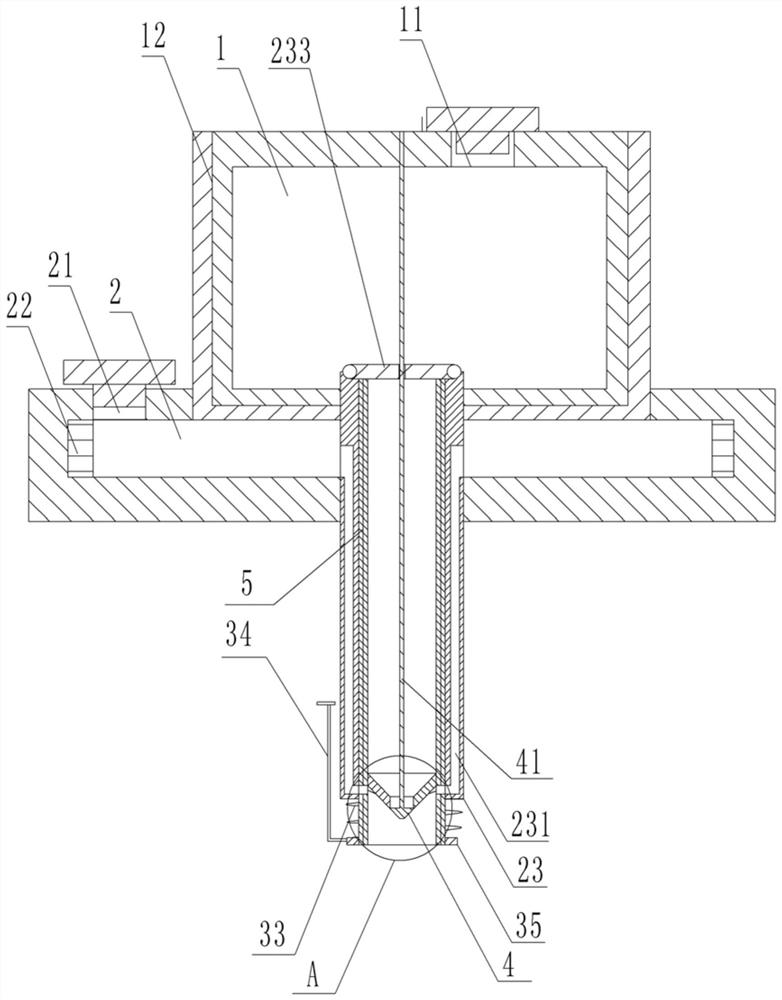

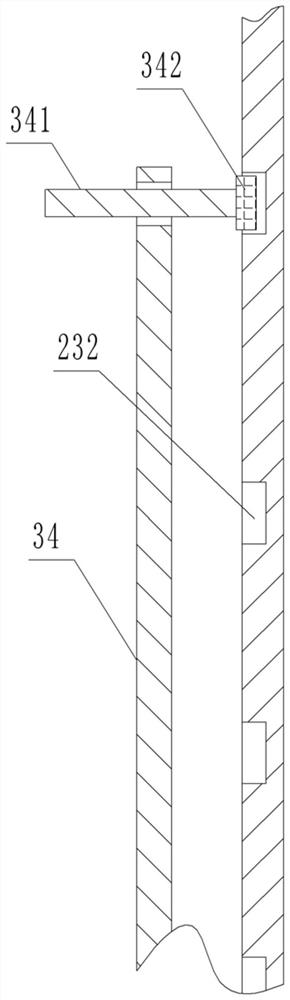

[0039] Step 3. Prepare sealing wax equipment: figure 1 As shown, the wax sealing device includes a device body with a convex cross-section, and the device body is composed of two cylinders, and the diameter of the upper cylinder is smaller than that of the lower cylinder. A sulfuric acid chamber 1 and a sulfuric acid port 11 for adding sulfuric acid to the sulfuric acid chamber 1 are arranged in the upper cylinder. A wax cavity 2 and a wax filling port 21 for adding wax to the wax cavity 2 are arranged in the lower cylinder, and caps for sealing are provided on the sulfuric acid port 11 and the wax filling port 21 . ...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is that, as Figure 6 As shown, the wax sealing equipment also includes a cooling part 6, the cooling part 6 includes a cooling box and a refrigeration pipe located in the cooling box; the cooling box is fixed on the upper surface of the equipment body; the upper end of the push rod 41 extends into the cooling box. It can be further ensured that the push rod 41 can transfer the cold source to the conical cover 4, so that the wax at the conical cover 4 can solidify quickly.

Embodiment 3

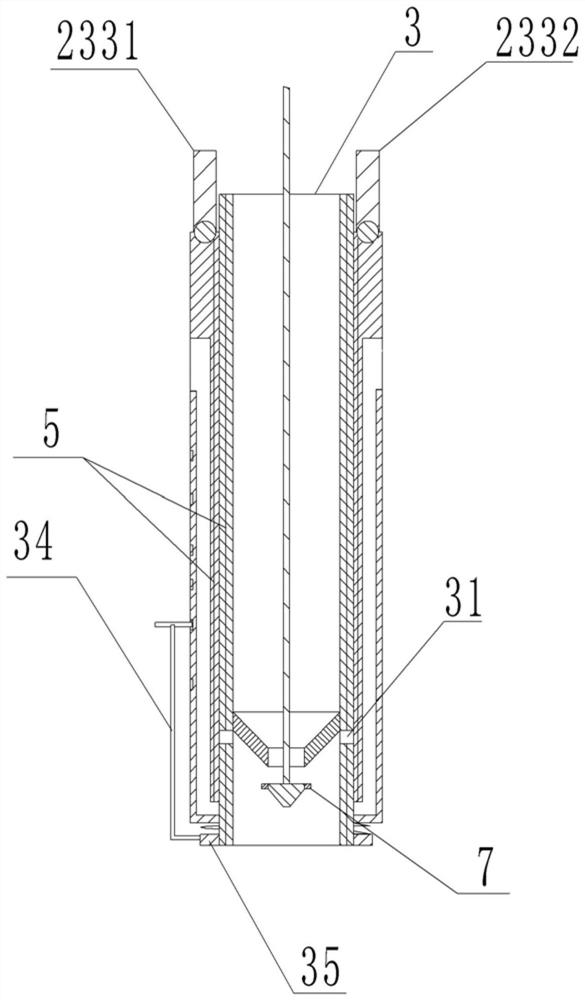

[0055] The difference between this embodiment and Embodiment 1 is that an inverted conical cover 4 is provided at the lower part of the acid discharge channel 321; a ring-shaped convex edge 7 is fixed on the edge of the upper surface of the conical cover 4 (such as Figure 7 As shown), the diameter of the annular convex edge 7 is greater than the diameter of the cylindrical channel 3212.

[0056] The upper surface of the conical cover 4 is fixed with an L-shaped push rod 71; the side wall of the acid filling pipe 3 is provided with a strip-shaped sliding port, and the upper end of the L-shaped push rod 71 passes through the strip-shaped sliding port and is fixedly connected with the wax filling pipe 23; The lower end of the acid filling pipe 3 stretches out the wax filling pipe 23, and a return spring 33 is also provided between the lower end of the acid filling pipe 3 and the wax outlet pipe; Thermal layer 5.

[0057] The L-shaped push rod 71 comprises a vertical bar 711 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com