Method for operating a household appliance and household appliance

A technology for household appliances and operation stage, applied in the field of running household appliances and household appliances, can solve problems such as detergent loss, and achieve the effect of reducing detergent loss and reducing pump power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

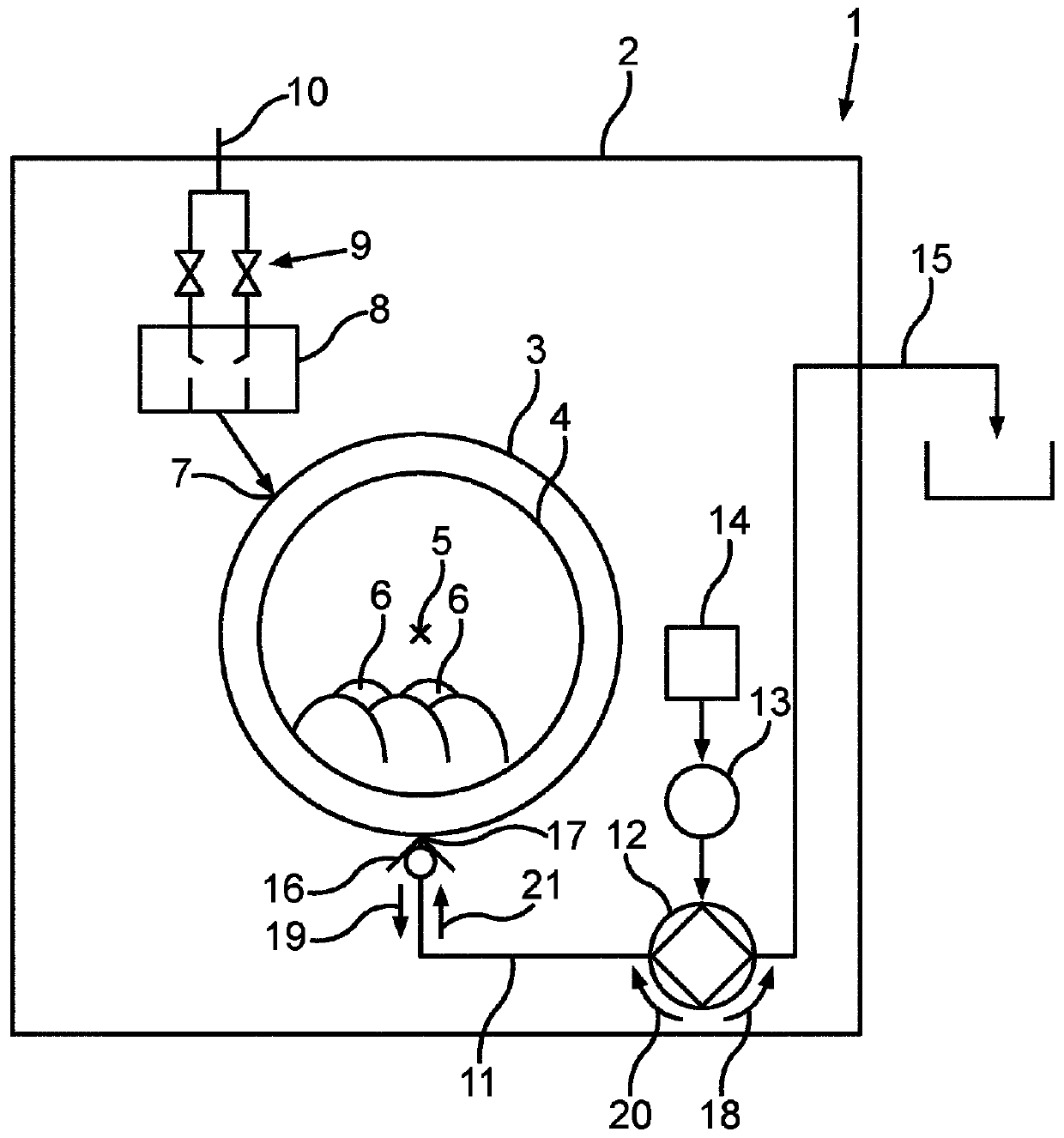

[0025] figure 1 The household appliance 1 shown in is constructed as a washing machine. The domestic appliance 1 has an appliance housing 2 in which a lye container 3 is arranged. The washing drum 4 is mounted in the lye container 3 so as to be rotatable about the axis of rotation 5 . The axis of rotation 5 is in this embodiment a horizontal axis of rotation. The laundry items 6 cleaned by means of the household appliance 1 are located in the laundry drum 4 .

[0026] The inlet 7 of the lye container 3 is fluidly coupled to the external water connection 10 of the household appliance 1 via the detergent box 8 and via the valve 9 . Detergent can be fed into the detergent box 8 in a manner known per se.

[0027] The base (or underside) of the lye container 3 is fluidly connected to an outflow line 11 , which is designed, for example, as a hose. A pump 12 is integrated into the outflow line 11 , which pump 12 is driven by an electric drive motor 13 . The drive motor 13 is ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com