Self-centering self-walking full-rotating high-pressure water pipeline coating cleaning device

A cleaning device, high pressure water technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

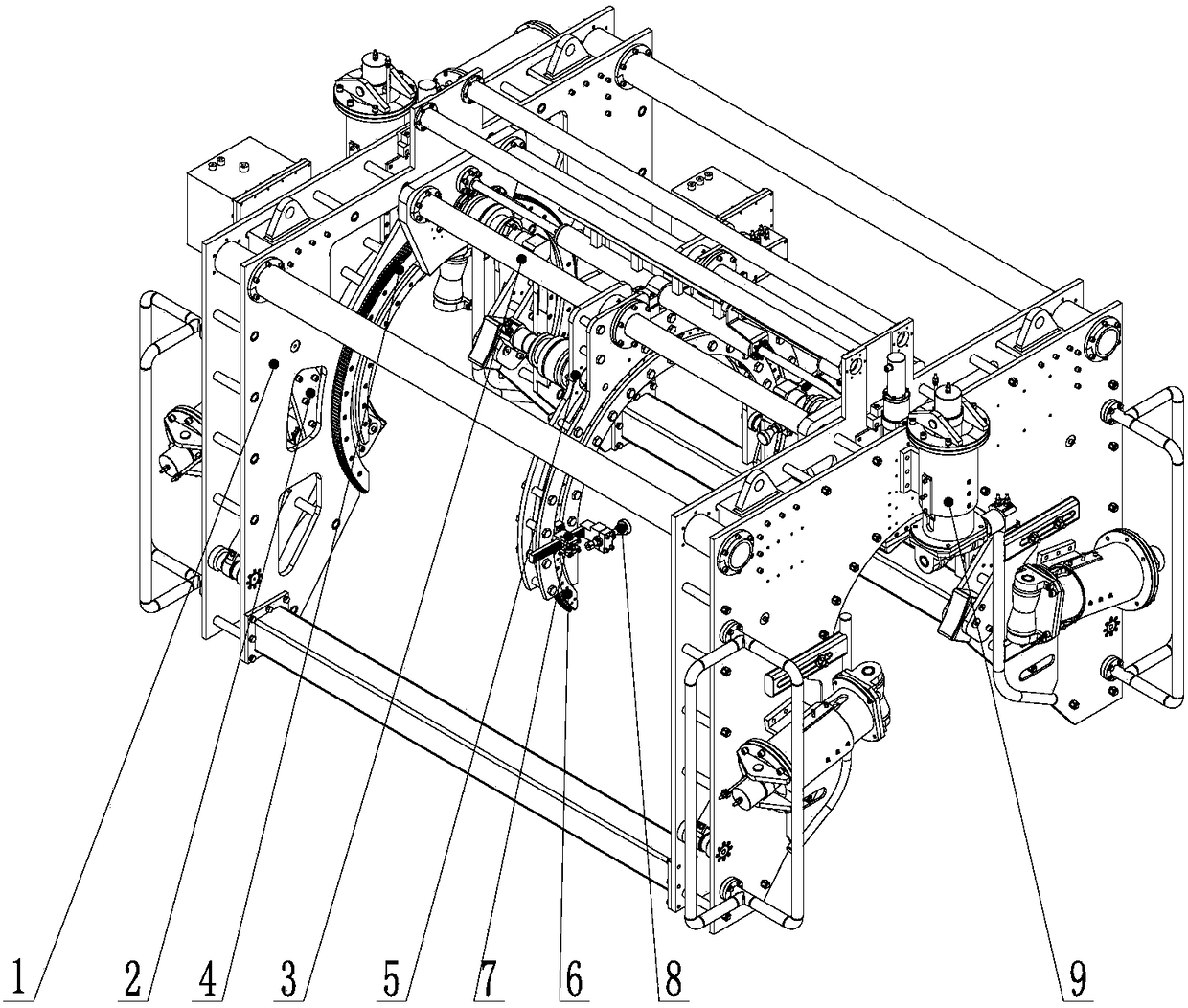

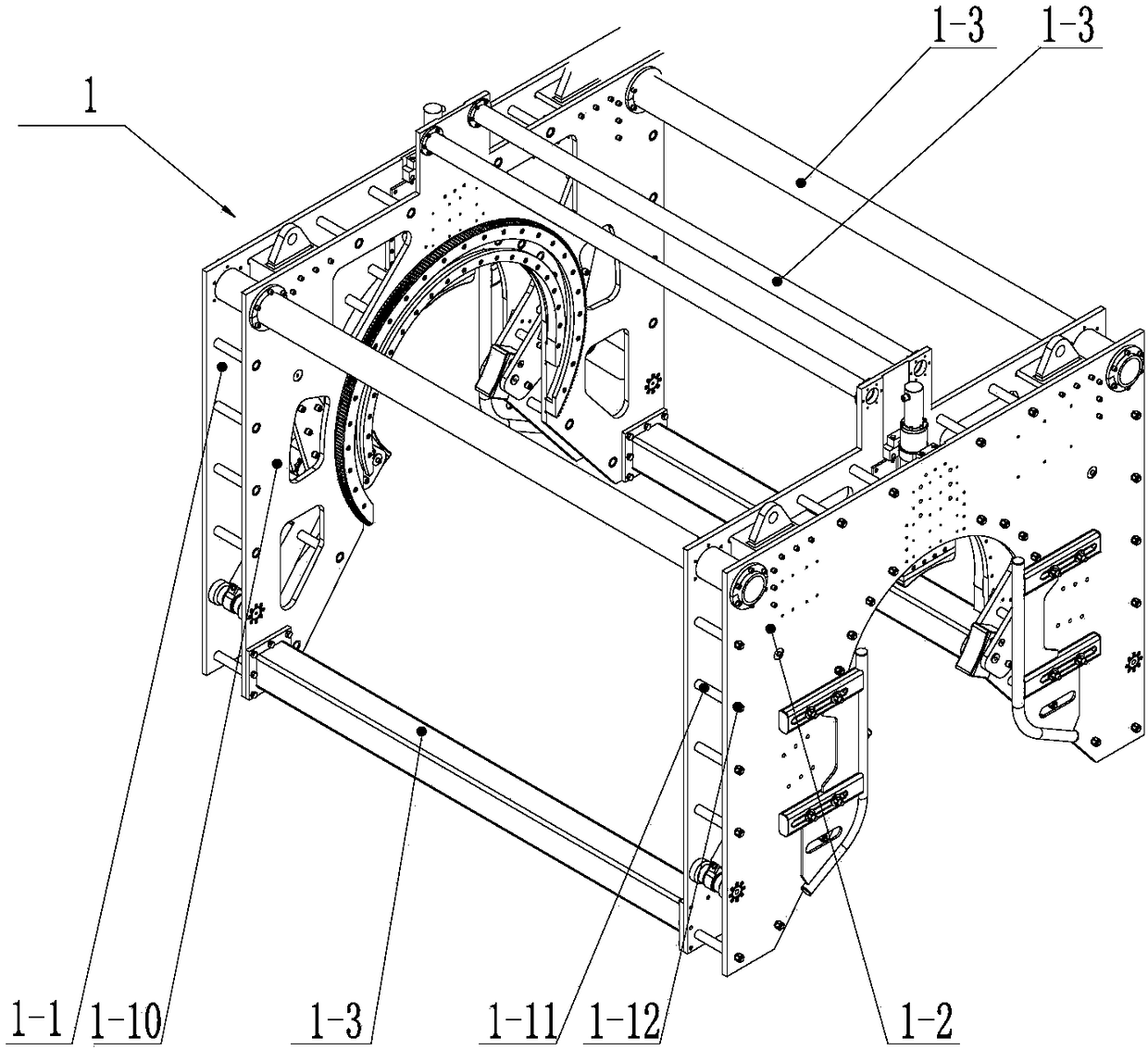

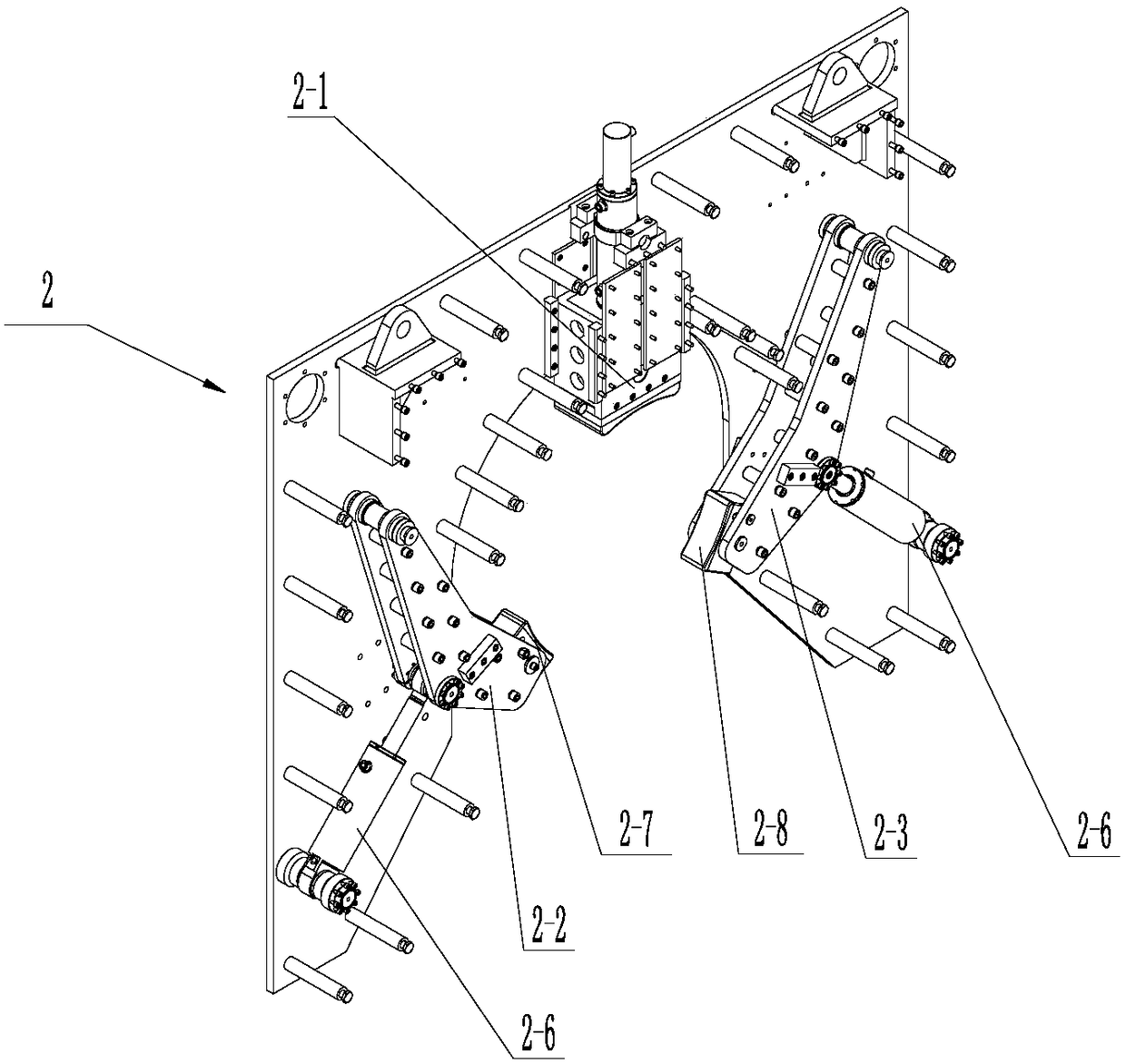

[0030] see Figure 1 to Figure 10 A self-centering self-propelled full-rotation high-pressure water pipeline coating cleaning device is characterized in that it includes a clamping and centering outer frame 1, two sets of clamping and centering mechanisms 2 with the same structure, a rotary and lateral movement mechanism 3, Two sets of internal rotary mechanism 4 with the same structure, nozzle rotary frame 5, nozzle rotary mechanism 6, nozzle radial adjustment mechanism 7, high-pressure water nozzle 8 and two sets of walking support mechanisms 9 with the same structure;

[0031] Wherein, the clamping and centering outer frame 1 is used to support all structures of the entire pipeline coating cleaning device; two sets of clamping and centerin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap