A kind of soapberry enzyme handmade soap and preparation method thereof

A handmade soap and sub-enzyme technology, applied in the direction of chemical instruments and methods, soap detergent compositions, surface-active non-soap compounds and washing compositions, etc., can solve the problem of unsatisfactory decontamination ability, high cost of saponin extraction, and poor quality Improvement and other issues, to achieve the effects of outstanding maintenance, high saponin content, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a kind of preparation method of soapberry color handmade soap, comprising the following steps:

[0034] S1, preparation of soap base

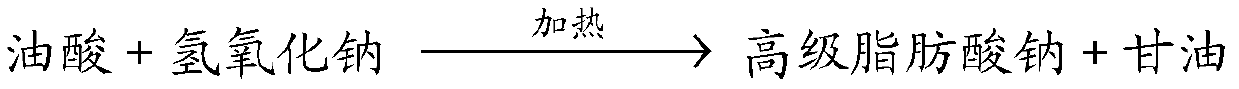

[0035] The reaction principle of making soap base from kitchen waste oil is as follows:

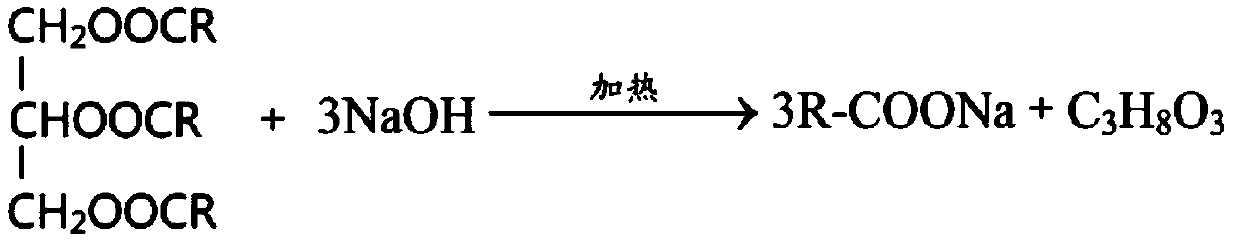

[0036] The present invention utilizes saponification method to directly carry out saponification reaction of oil and alkali to prepare soap base, and the principle is represented by the following chemical reaction formula:

[0037]

[0038]

[0039] The kitchen waste oil is saponified with sodium hydroxide to obtain basic salts of higher fatty acids or mixed fatty acids. Its general chemical formula can be expressed as: RCOONa, where R represents a long carbon chain alkyl group, and glycerin is produced. The resulting soap base has good washing, decontamination, cleaning, moisturizing and other functions.

[0040] The steps for preparing soap base are as follows:

[0041] S11, waste oil pretreatment

[0042] In addit...

Embodiment 1

[0063] A preparation method of soapberry enzyme handmade soap, comprising the following steps:

[0064] S1, preparation of soap base

[0065] S11, waste oil pretreatment

[0066] S111, degumming

[0067] Kitchen waste oil is first filtered to remove insoluble impurities, then heated to 40°C in a water bath, and mixed with phosphoric acid. The volume ratio of kitchen waste oil to phosphoric acid is 10:1, and the obtained oil-acid mixture is stirred at 40°C and 1000rpm for 10 minutes , stand still at room temperature to coagulate the colloid, separate the oil phase liquid and the condensate in the upper layer, and heat the oil phase liquid in a water bath at 100 ° C for 2 hours to obtain degummed grease;

[0068] S112, decolorization, deodorization

[0069] Heat the degummed grease of S111 to 95°C, mix it with activated clay, the mass ratio of degummed grease to activated clay is 3:1, then press-filter the adsorbed mixture of clay and degummed grease, and the collected filtra...

Embodiment 2

[0081] A preparation method of soapberry enzyme handmade soap, comprising the following steps:

[0082] S1, preparation of soap base

[0083] S11, waste oil pretreatment

[0084] S111, degumming

[0085] Kitchen waste oil is first filtered to remove insoluble impurities, then heated to 50°C in a water bath, and mixed with phosphoric acid. The volume ratio of kitchen waste oil to phosphoric acid is 10:2, and the obtained oil-acid mixture is stirred at 50°C and 1000rpm for 10 minutes , stand still at room temperature to coagulate the colloid, separate the oil phase liquid and the condensate in the upper layer, and heat the oil phase liquid in a water bath at 100 ° C for 2 hours to obtain degummed grease;

[0086] S112, decolorization, deodorization

[0087] Heat the degummed oil of S111 to 105°C, mix it with activated clay, the mass ratio of degummed oil and activated clay is 3:2, then press filter the adsorbed mixture of clay and degummed oil, and the collected filtrate is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com