Subminiature harmonic reducer with integration of bearing and harmonic wave

A harmonic reducer, ultra-small technology, applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of large volume and weight, difficulty in manufacturing reducers, etc., to achieve small size and reduce structure The number of parts, the effect of improving installability and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

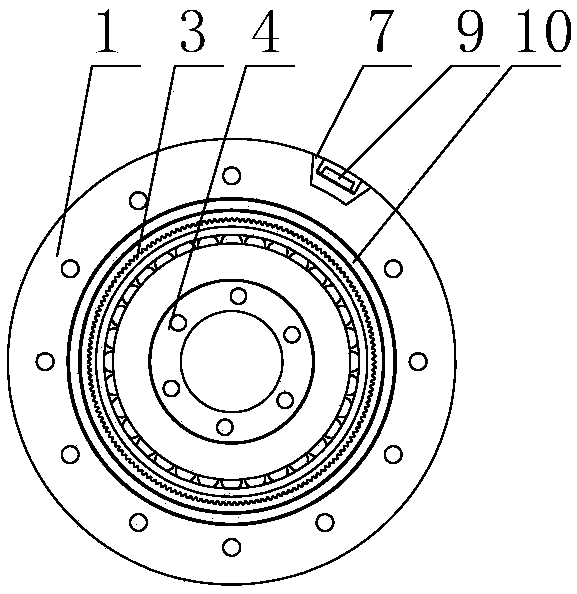

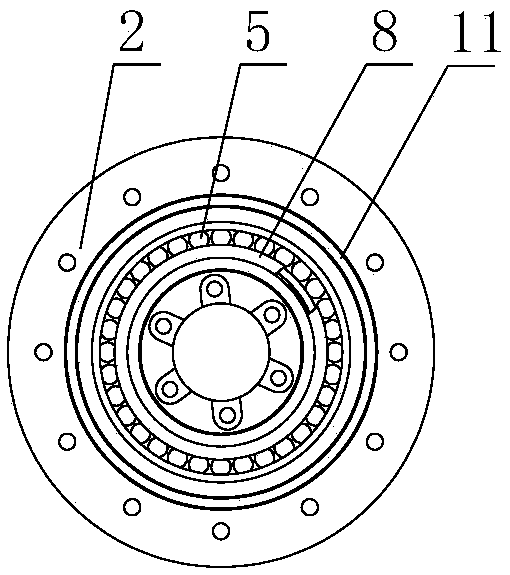

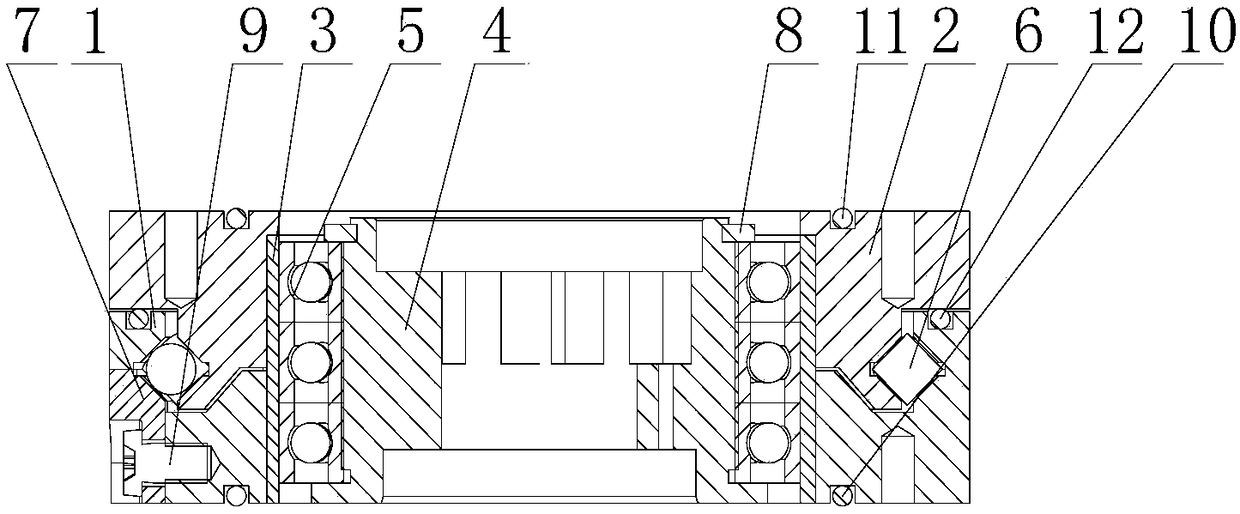

[0031] Such as Figure 1 ~ Figure 3 As shown, the present invention provides an ultra-small harmonic reducer with an integrated design of bearings and harmonics, including a steel wheel a1, a steel wheel b2, a flexible wheel 3, a cam 4, a flexible bearing 5, a roller 6, and a roller Block 7, bearing retaining ring 8 and mounting screw 9. In addition, the harmonic reducer of the present invention also includes a sealing ring a10, a sealing ring b11 and a sealing ring c12.

[0032] The steel wheel a1 and the roller block 7 are connected together by mounting screws 9 to form an input steel wheel or an output steel wheel, and correspondingly, the steel wheel b2 is used as an output steel wheel or an input steel wheel. The inner ring of the steel wheel a1 has two parts with a larger diameter and a smaller one. A V-shaped ring groove is processed on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com