Flow sensor

A flow sensor and fluid technology, applied in the field of flow sensors, can solve the problems of flow measurement influence, bubble inclusion, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

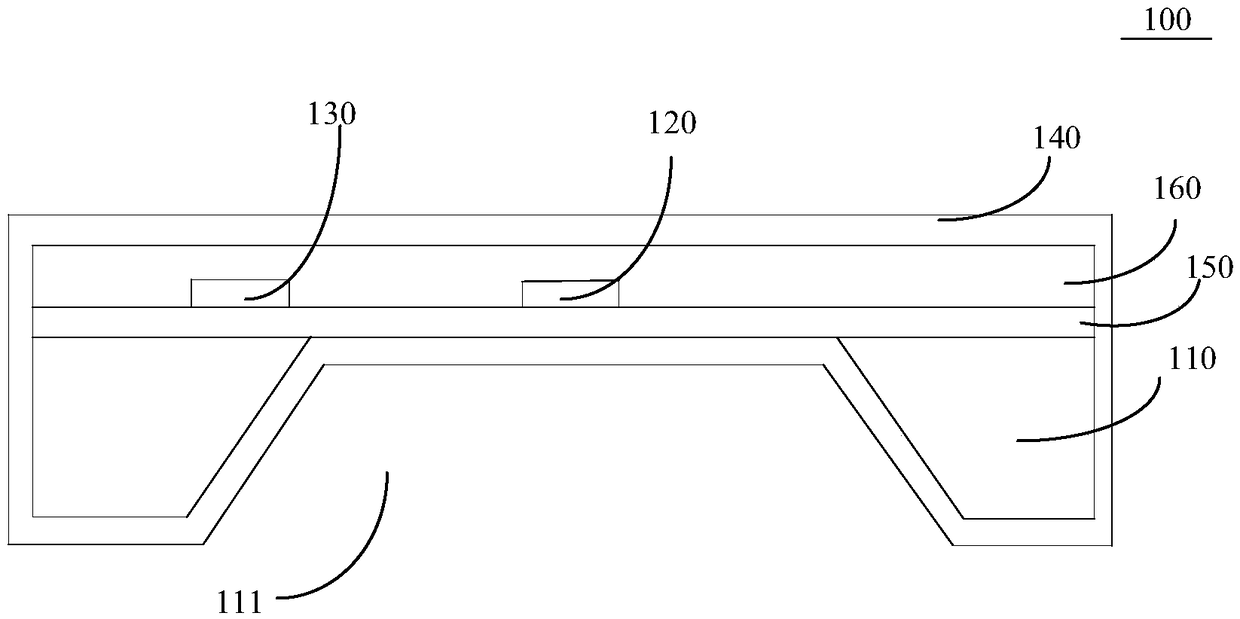

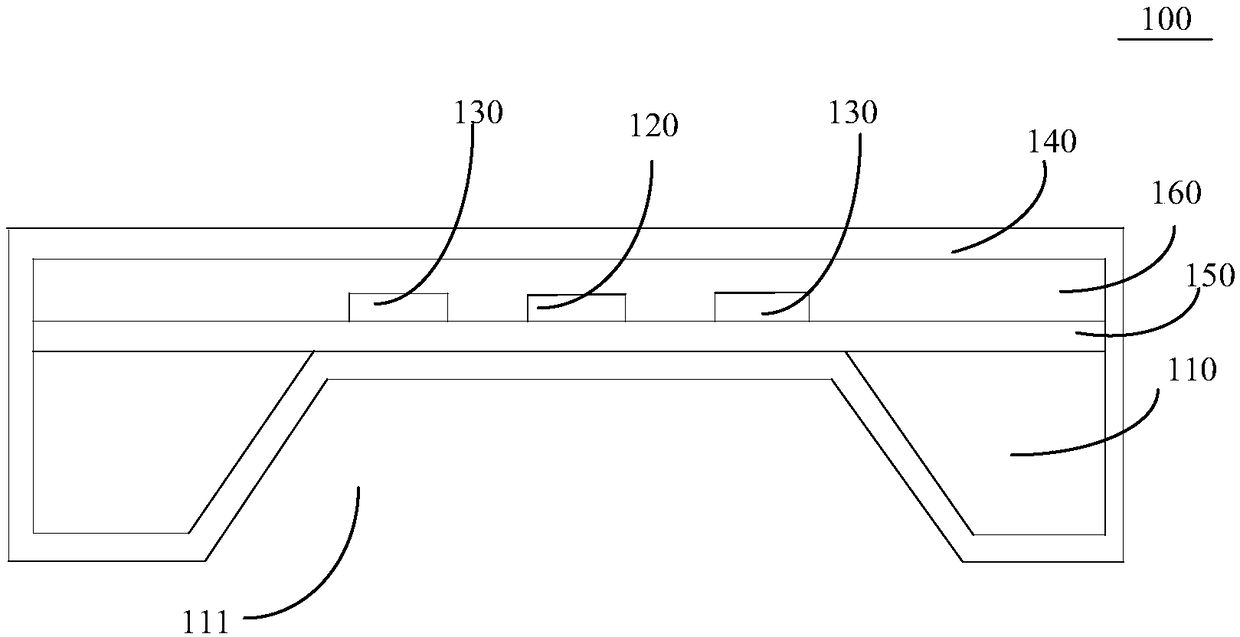

[0040] like figure 1 As shown, the present invention relates to a flow sensor 100 comprising a substrate 110 , a heating element 120 , at least one temperature sensing element 130 and a hydrophilic layer 140 . Wherein, both the heating element 120 and the temperature sensing element 130 are formed on the substrate 110 . Moreover, there is a predetermined interval between the temperature sensing element 130 and the heating element 120 , so as to obtain the flow rate of the fluid passing through the flow sensor 100 by measuring the temperature change of the temperature sensing element 130 or the heating element 120 . The hydrophilic layer 140 covers the entire o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com