Pressure gauge and pressure monitoring system

A pressure gauge and pressure mode technology, which is used in the measurement of fluid pressure, measuring devices, instruments, etc., can solve the problems of data reliability, low intelligence of pressure gauges, and inability to detect real-time pressure gauge data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

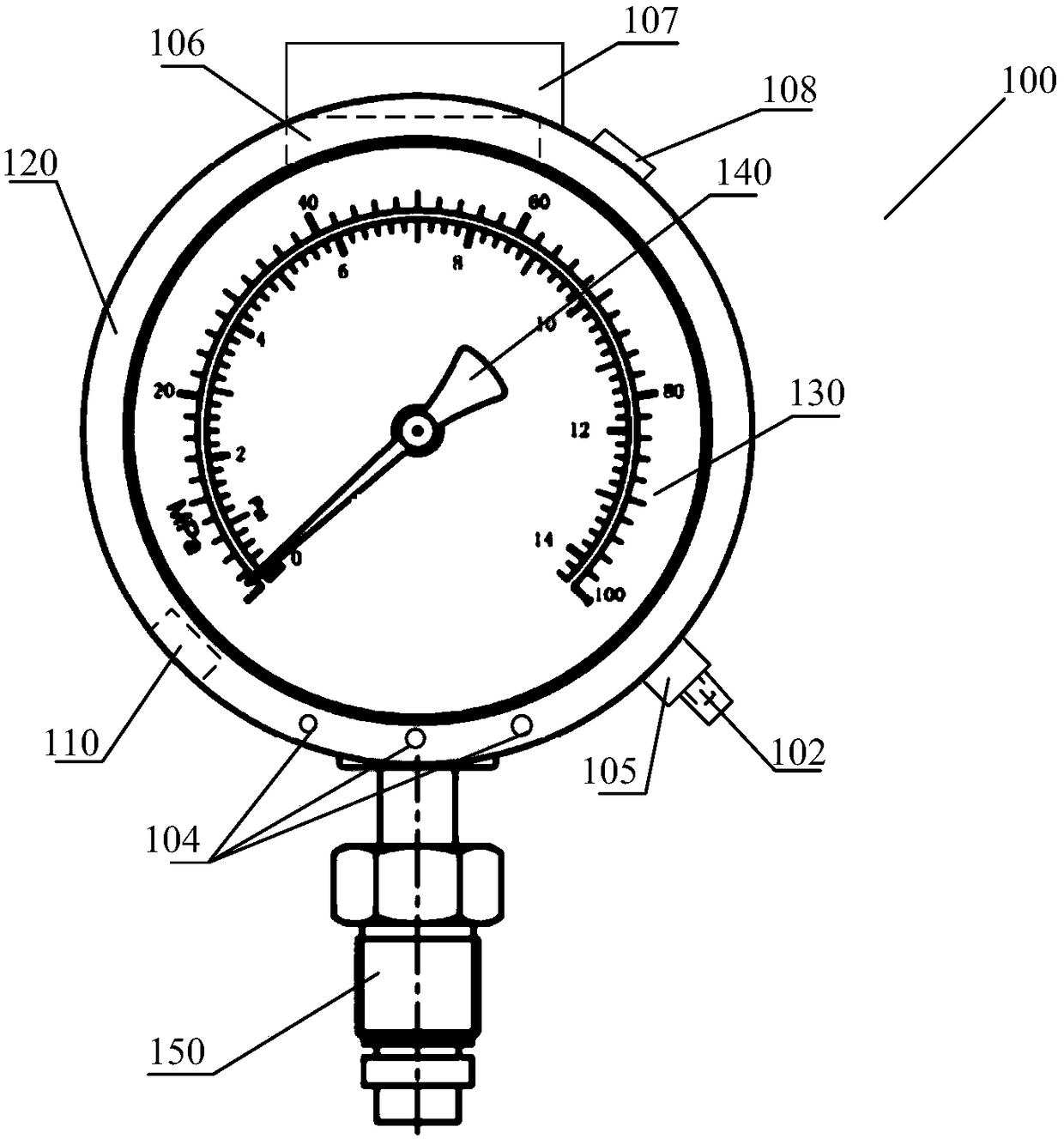

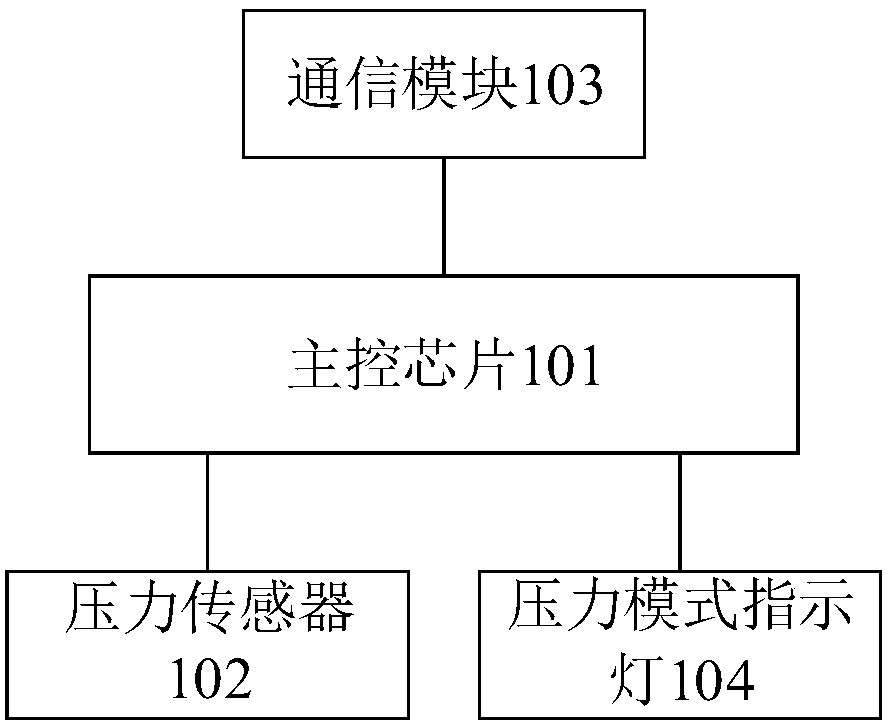

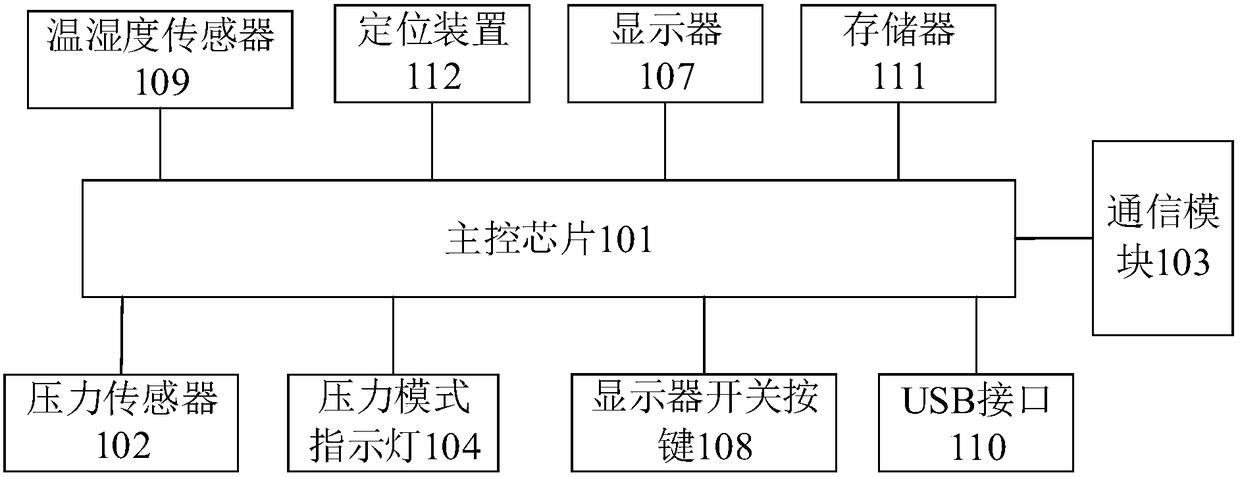

[0034] See figure 1 with figure 2 The pressure gauge 100 provided in this embodiment includes a pressure gauge body, which includes a pressure gauge housing 120, a dial 130, a pointer 140, a pressure connector 150, and a glass panel (not shown in the figure) covering the dial. A main control chip 101, a pressure sensor 102, and a communication module 103 are arranged in the pressure gauge housing 120, and a plurality of pressure mode indicator lights 104 are arranged on the surface of the pressure gauge housing. The pressure sensor, the communication module, and the pressure mode indicator are respectively connected to the main control chip; the main control chip is connected to the background monitor through the communication module, and the pressure connector 150 is connected to the SF6 gas.

[0035] In a possible embodiment, the pressure gauge body is a spring tube pressure gauge, and the pressure gauge housing is made of stainless steel. The glass panel can be made of toughe...

Embodiment 2

[0049] Figure 4 Shows a schematic structural diagram of a pressure monitoring system provided by an embodiment of the present invention, such as Figure 4 As shown, the pressure monitoring system includes a background monitoring machine 200 and a pressure gauge 100 as in the first embodiment; the pressure gauge is in communication connection with the background monitoring machine.

[0050] Specifically, the background monitoring machine obtains the pressure value through the communication module, analyzes the change trend of the pressure value, and predicts the change of the pressure value in advance, and does a good job of tracking and processing equipment leakage defects in time. Specifically, the pressure value at the current moment is extracted every preset time length, and when the pressure value reaches the preset number, the average difference of the pressure values is calculated, and the pressure value is determined according to the average difference, the preset durat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com