Voice coil motor with relatively high performance

A voice coil motor, the best technology, applied in the field of voice coil motors, can solve the problems of unable to adjust the far focus, difficult to enlarge the structure, long focusing time, etc., to achieve the effect of prolonging the standby time, improving characteristics, and fast focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

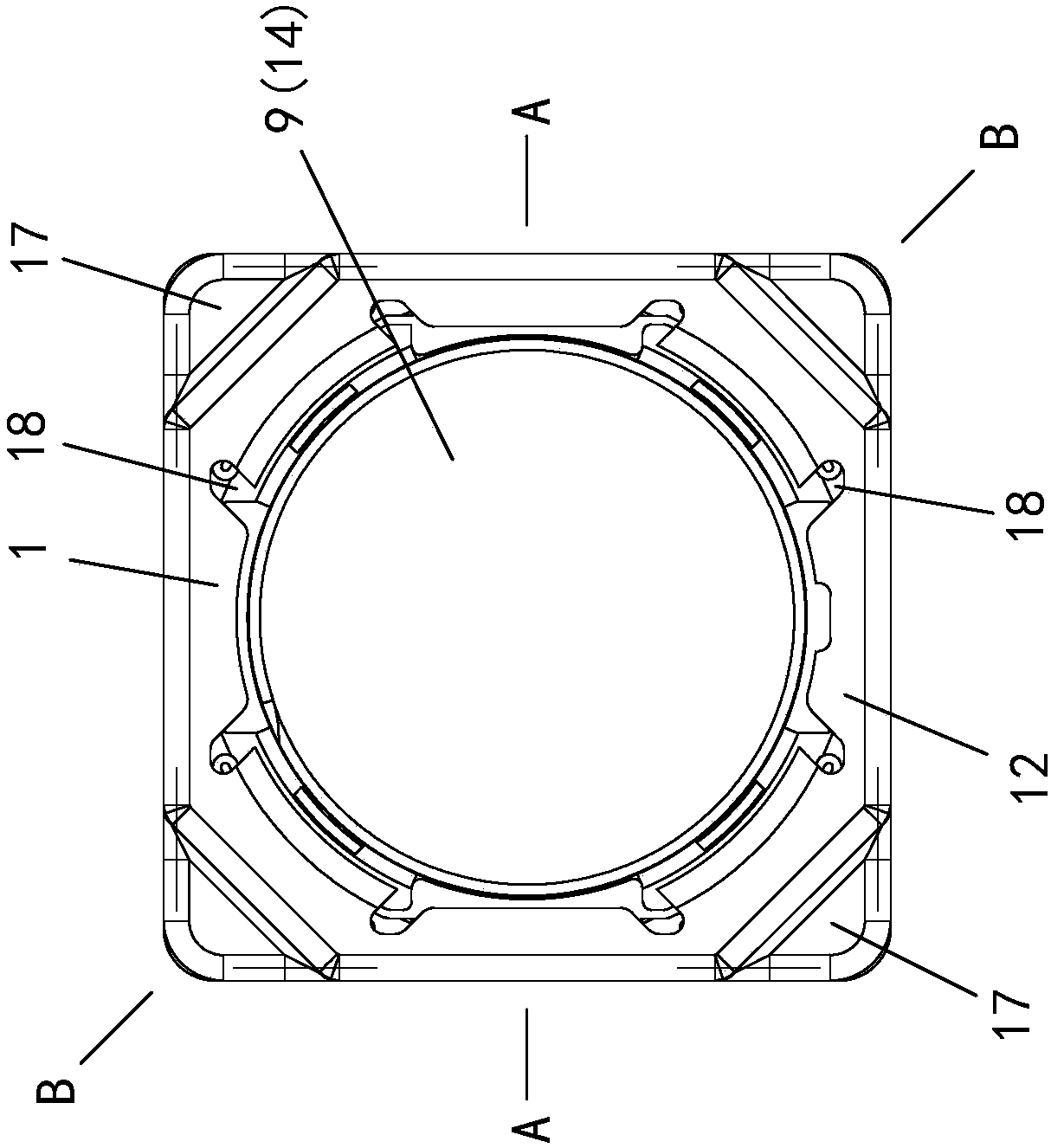

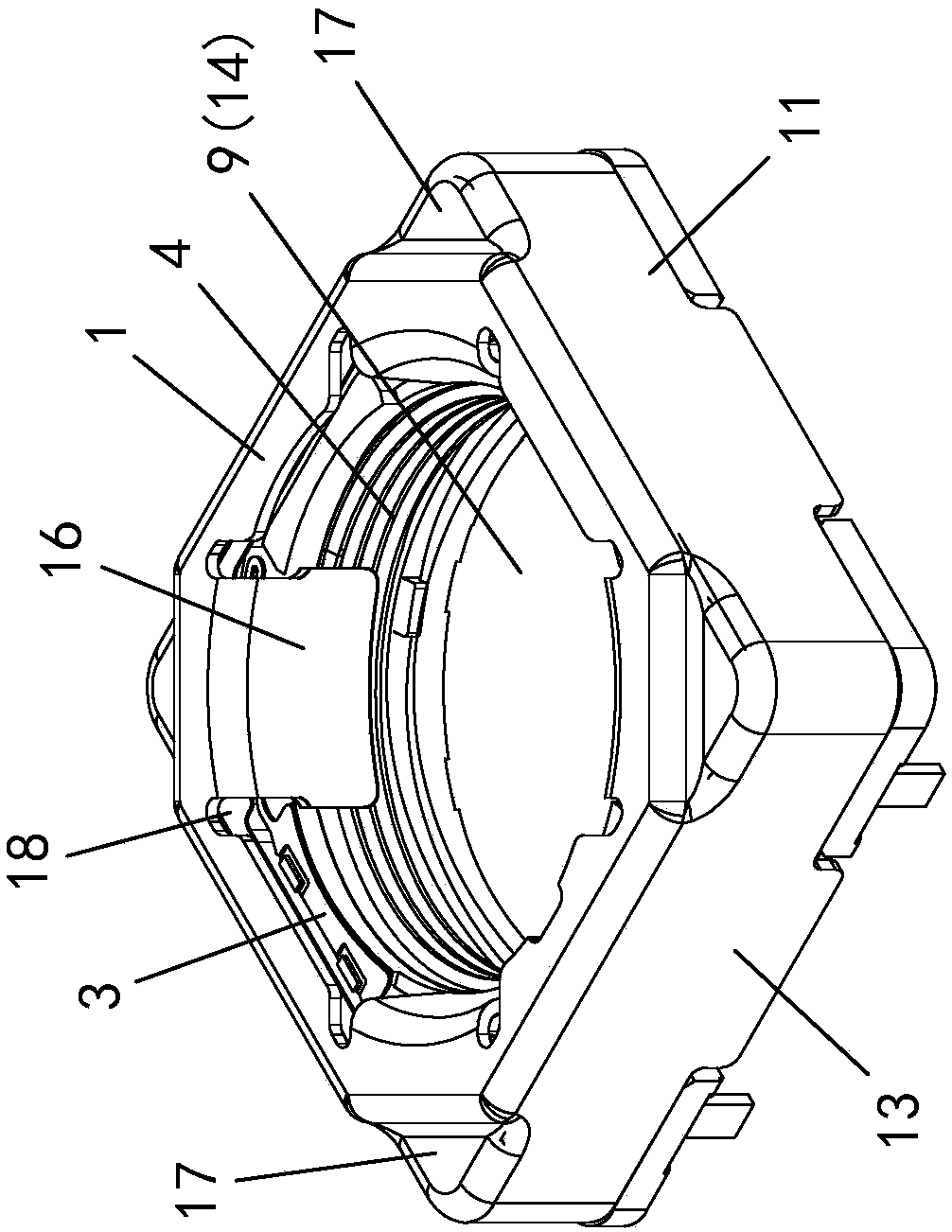

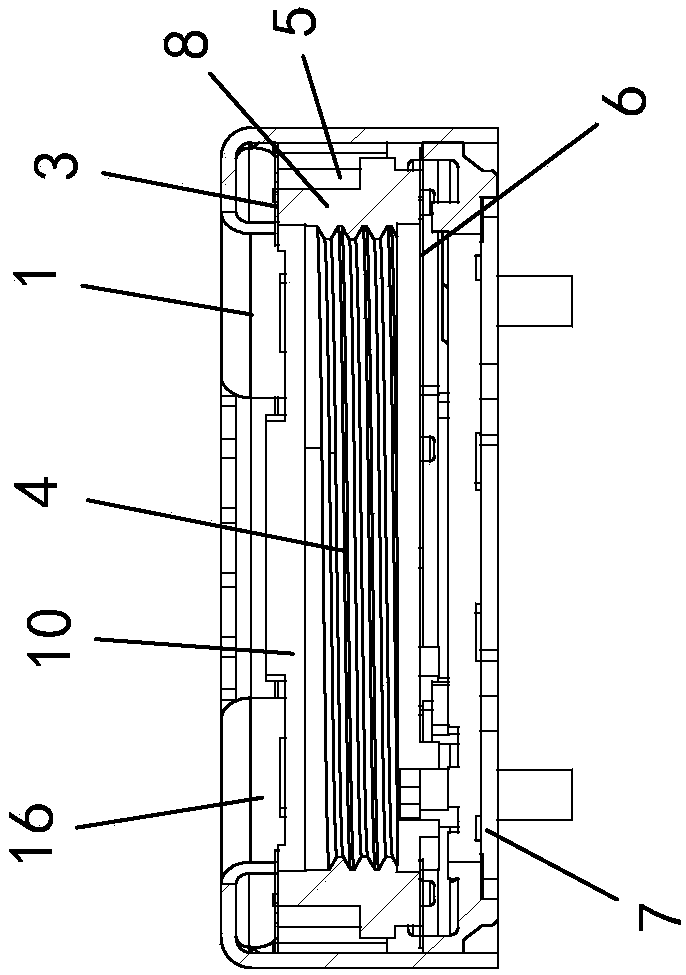

[0036] Example: see attached Figure 1~6 As shown, a voice coil motor with better performance is formed by assembling and positioning the first assembly body and the second assembly body in the up and down direction; through the combined assembly form of the two assemblies, the assembly efficiency of the voice coil motor can be improved and the Product yield.

[0037] The first assembly includes a yoke 1, a magnet 2 and an upper elastic piece 3; the magnet 2 is fixed inside the yoke 1 in the circumferential direction, and the first elastic end of the upper elastic piece 3 is positioned on the yoke Below the top cover of Iron 1;

[0038] The second assembly includes a carrier 4, a coil 5, a lower elastic piece 6 and a base 7; the carrier 4 includes a seat 8, and a first through hole 9 is opened in the seat 8 along the up and down direction for assembling the lens of the camera The upper end surface of the seat body 8 is adhesively connected to locate the second elastic end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com