Automatic welding machine for plane steel plates

An automatic welding machine and steel plate technology, which is applied to welding equipment, welding accessories, welding/welding/cutting items, etc., can solve the problems of inconvenient movement, low welding efficiency, and inability to guarantee welding quality, and achieve high welding efficiency and reduced loss, good effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

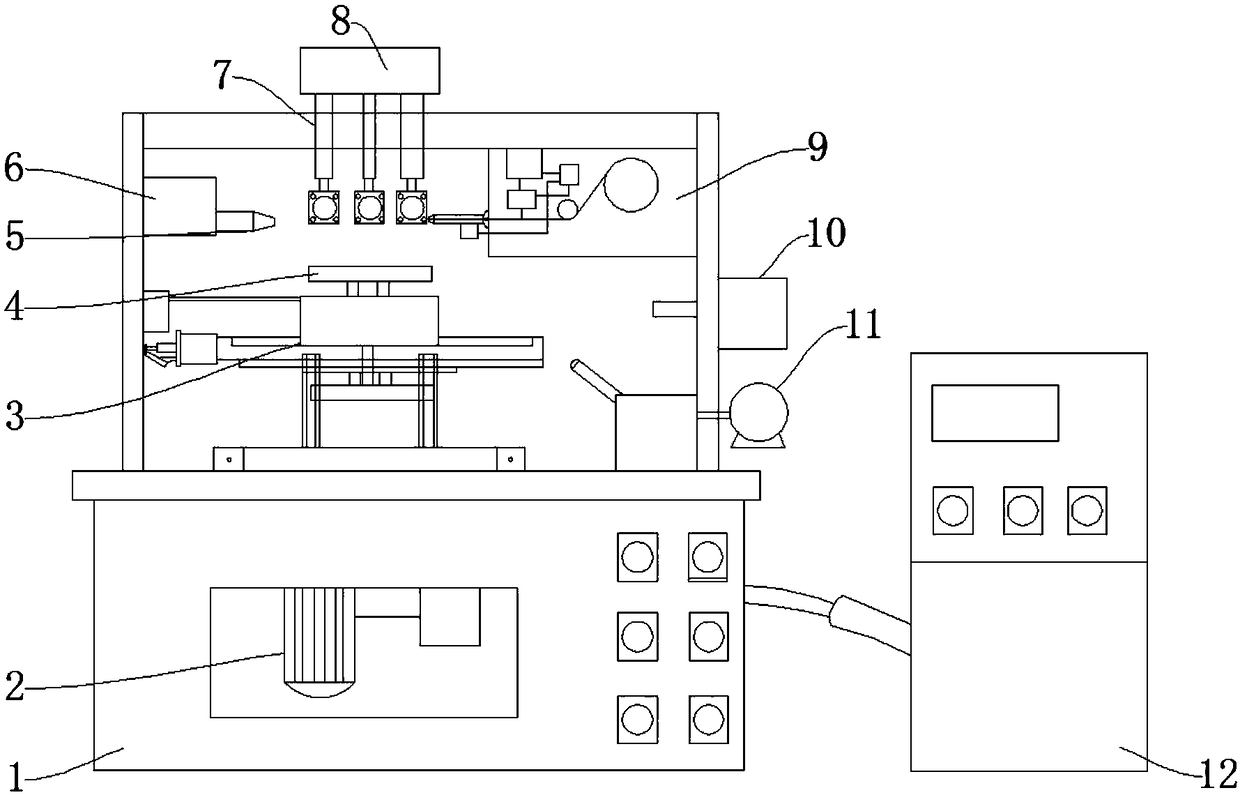

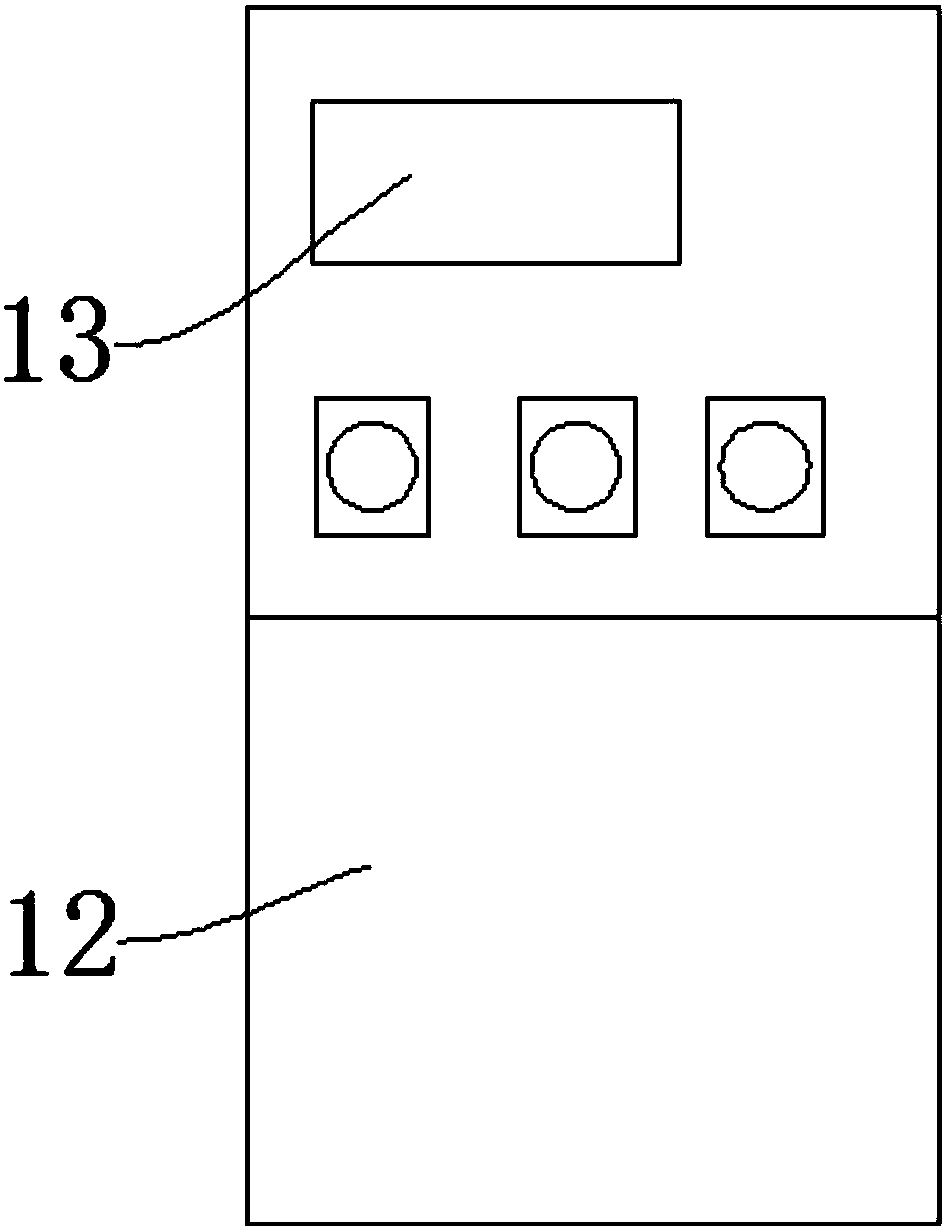

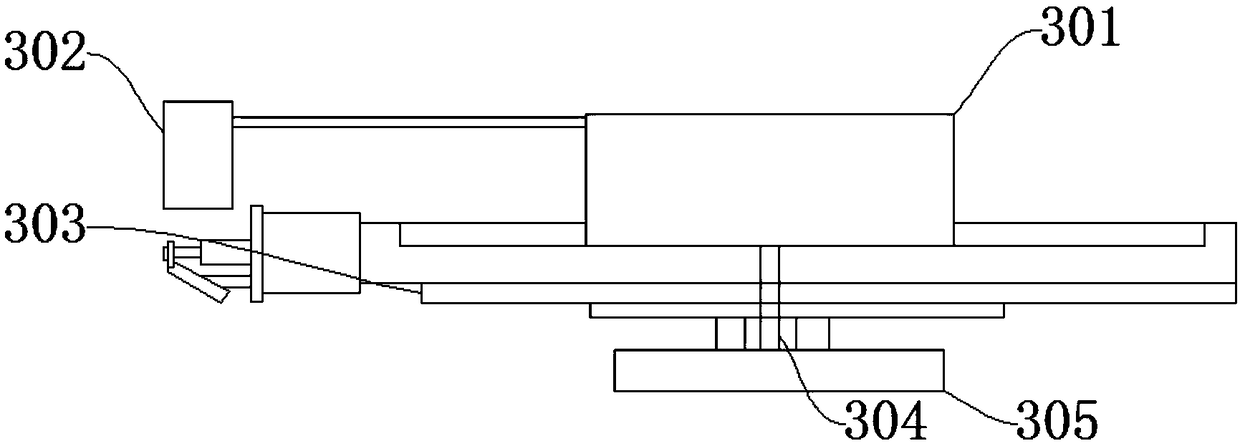

[0028] Such as Figure 1-Figure 8 As shown, a flat steel plate automatic welding machine includes a fixed base 1, a servo frequency conversion motor 2, a steel plate mobile platform 3, a steel plate placement table 4, an infrared generator 6, a telescopic hydraulic rod 7, and a push hydraulic cylinder 8. The fixed base 1 is provided with the servo variable frequency motor 2 inside, a motor reduction box 18 is installed on one side of the servo variable frequency motor 2, the steel plate moving platform 3 is set above the servo frequency variable motor 2, and the steel plate moving platform 3 is set above There is a top support platform 301, a support platform regulator 302 is installed on one side of the top support platform 301, a mobile chute 303 is installed below the top support platform 301, and a main drive shaft 304 is installed below the mobile chute 303, An adjust...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap