Sleeve-connection fixing device for feeding and hanging column for milk tea processing

A fixing device and material feeding technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of inconvenient and fast installation, use or disassembly, non-adjustable height of socket feeding hanging columns, and difficulty in disassembly, etc. To achieve the effect of ensuring universality, small footprint and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

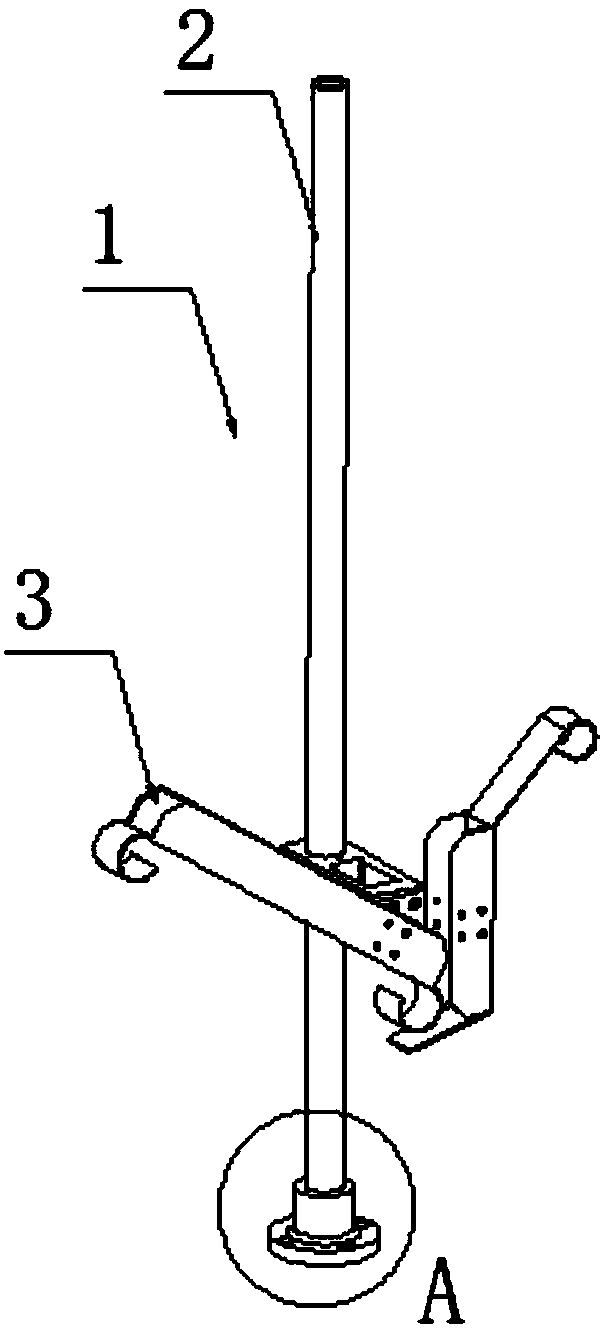

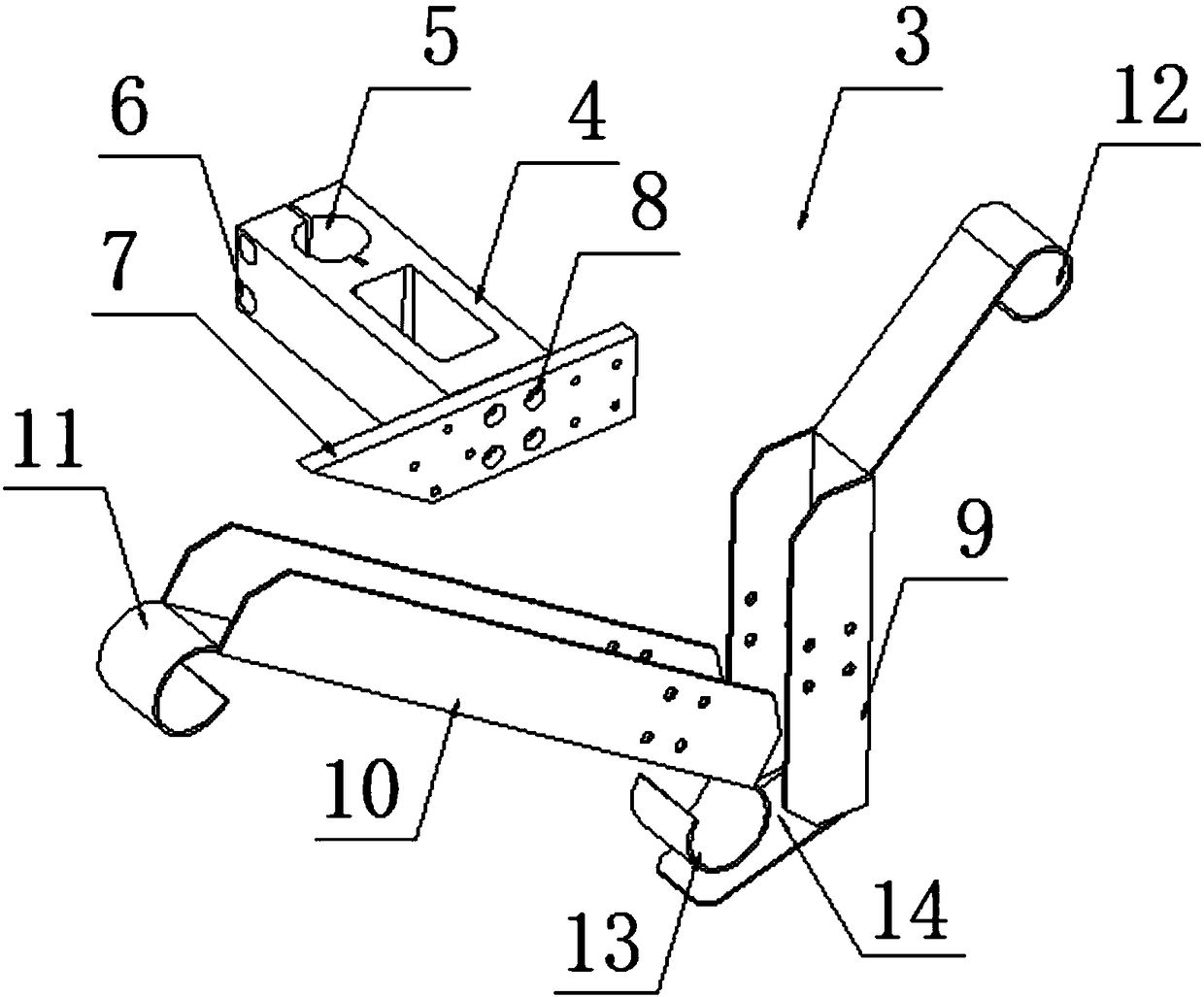

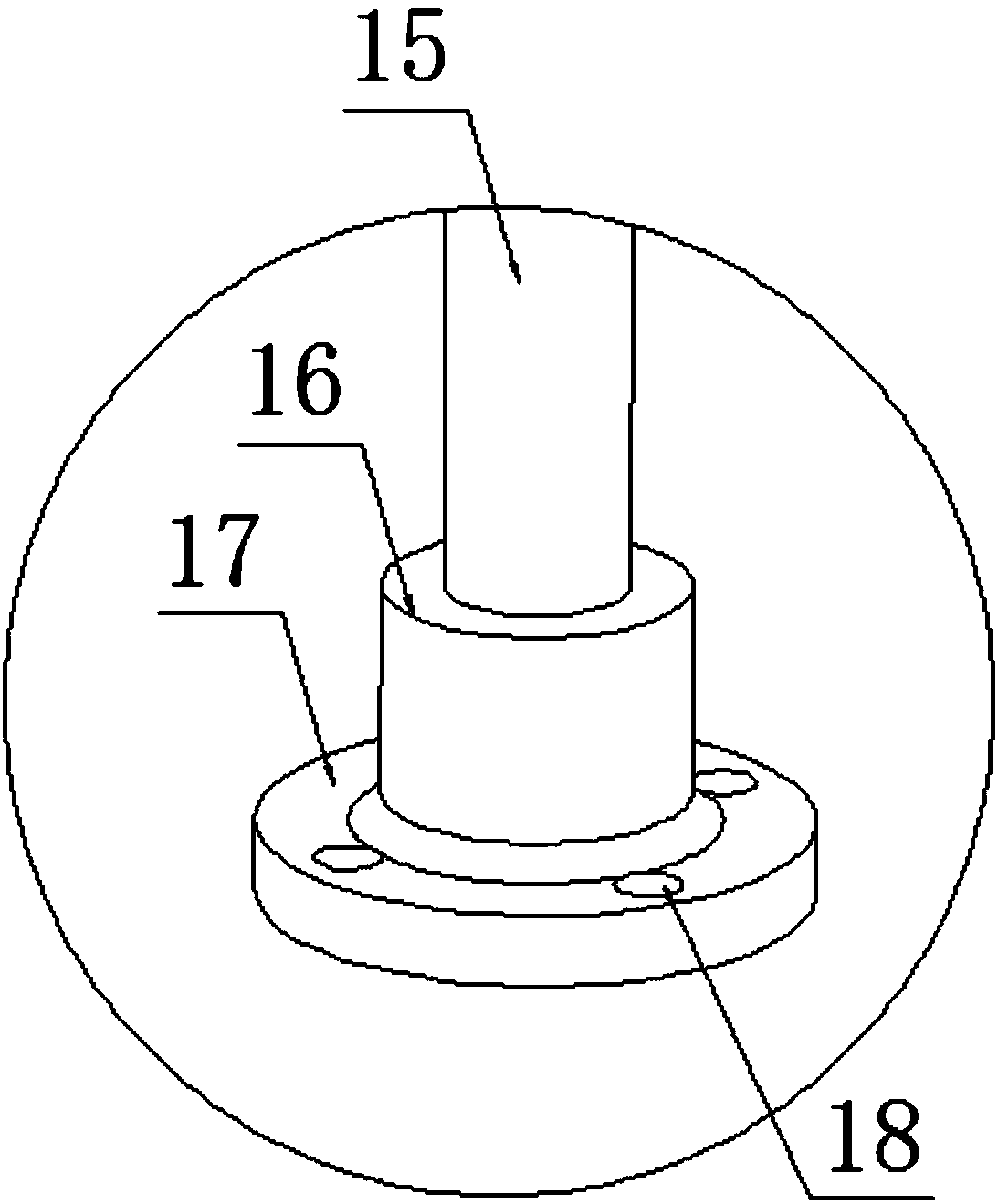

[0018] Such as Figure 1 to Figure 3 As shown, the socket fixing device 1 for feeding and hanging columns during milk tea processing includes a supporting frame 2 and a set of discs 3, and a connecting frame 4 is installed on the set of discs 3, and a connecting frame 4 is arranged on the connecting frame 4. Connecting plate 7, four second bolt holes 8 are arranged at equal intervals on the connecting plate 7, a vertical support plate 9 is installed on the connecting frame 4, and a slanting support plate 10 is installed on one side of the vertical support plate 9. One end of the support plate 10 is provided with a first set of perforations 11, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com