Honey subpackage device

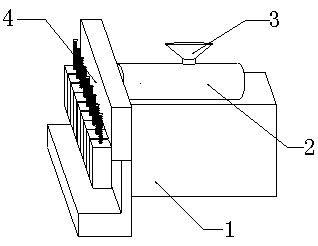

A technology of sub-packaging and honey, applied in packaging, liquid bottling, transportation and packaging, etc., can solve the problems of low work efficiency and difficulty in quantitative sub-packaging, and achieve high work efficiency and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

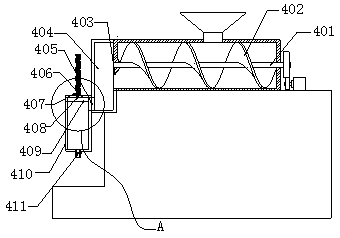

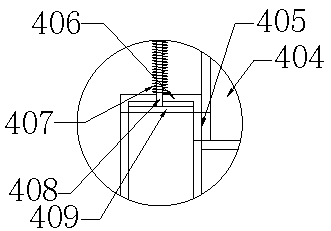

[0020] Specific implementation: during use, the staff connects the motor to an external power supply, the motor drives the pinion to rotate, the pinion drives the large gear to rotate, the large gear rotates to drive the rotating shaft 401 to rotate, and the rotating shaft 401 rotates to drive the auger blade 402 Rotate, the worker pours the honey into the conveying cylinder 2 through the feeding hopper 3, under the action of the auger blade 402, the honey moves to the left along the conveying cylinder 2, and then the honey is discharged to the inside of the containing box 404 through the discharge port 403 , and then flow into the measuring box 406 through the communication hole 405, the worker places the material bottle on the upper side of the support 1 on the lower side of the output pipe 411, when the honey in the measuring box 406 accumulates to the predetermined scale line position, the worker Press the disk downward, the movement of the disk drives the pressure rod 408 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com