Polymer containing asu side chain, preparation method thereof and anion exchange membrane based on the polymer

An anion exchange membrane and polymer technology, applied in the field of fuel cell and polymer material synthesis, achieves the effects of convenient post-modification, wide applicability and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

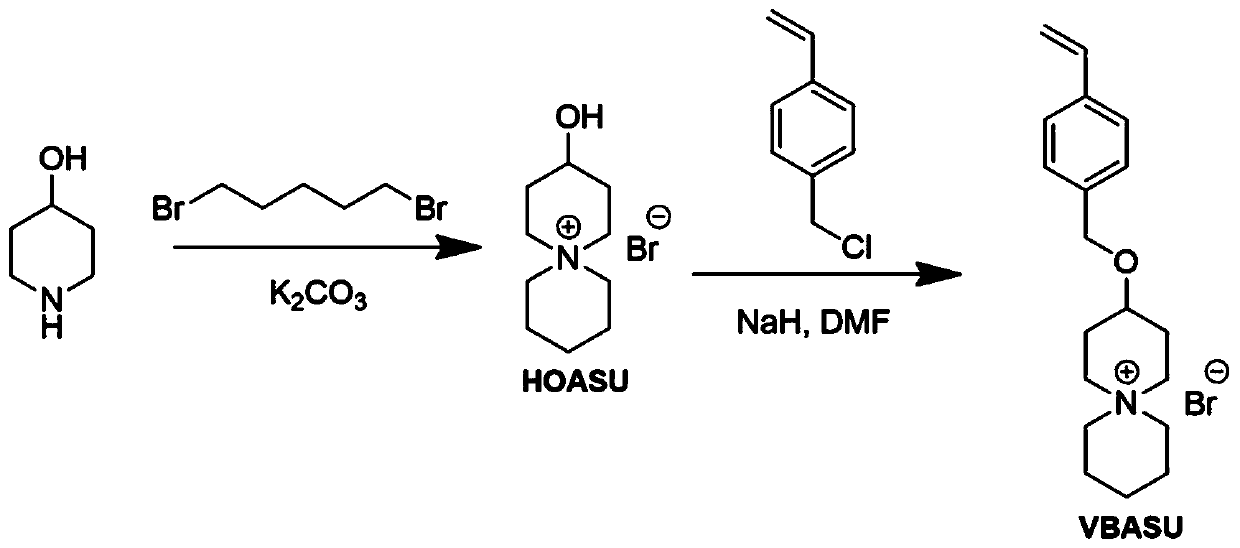

[0023] 1) Synthesis of HOASU

[0024] Weigh 4.2g (30mmol) of potassium carbonate and 5.75g (25mmol) of 1,5-dibromopentane, dissolve them in 50mL of acetonitrile, and heat to boiling. 2.53g (25mmol) of 4-hydroxypiperidine was dissolved in 10 acetonitrile, slowly added dropwise to the above boiling solution, and then heated to reflux for 12h. Cool, remove the solvent by rotary evaporation, add 70mL of ethanol, remove the formed potassium bromide and unreacted potassium carbonate by filtration, rotary evaporate the filtrate to 20mL, slowly add 80mL of ether, and precipitate a white solid product. Suction filtration and drying yielded 4.4 g of the product. (yield: 70%)

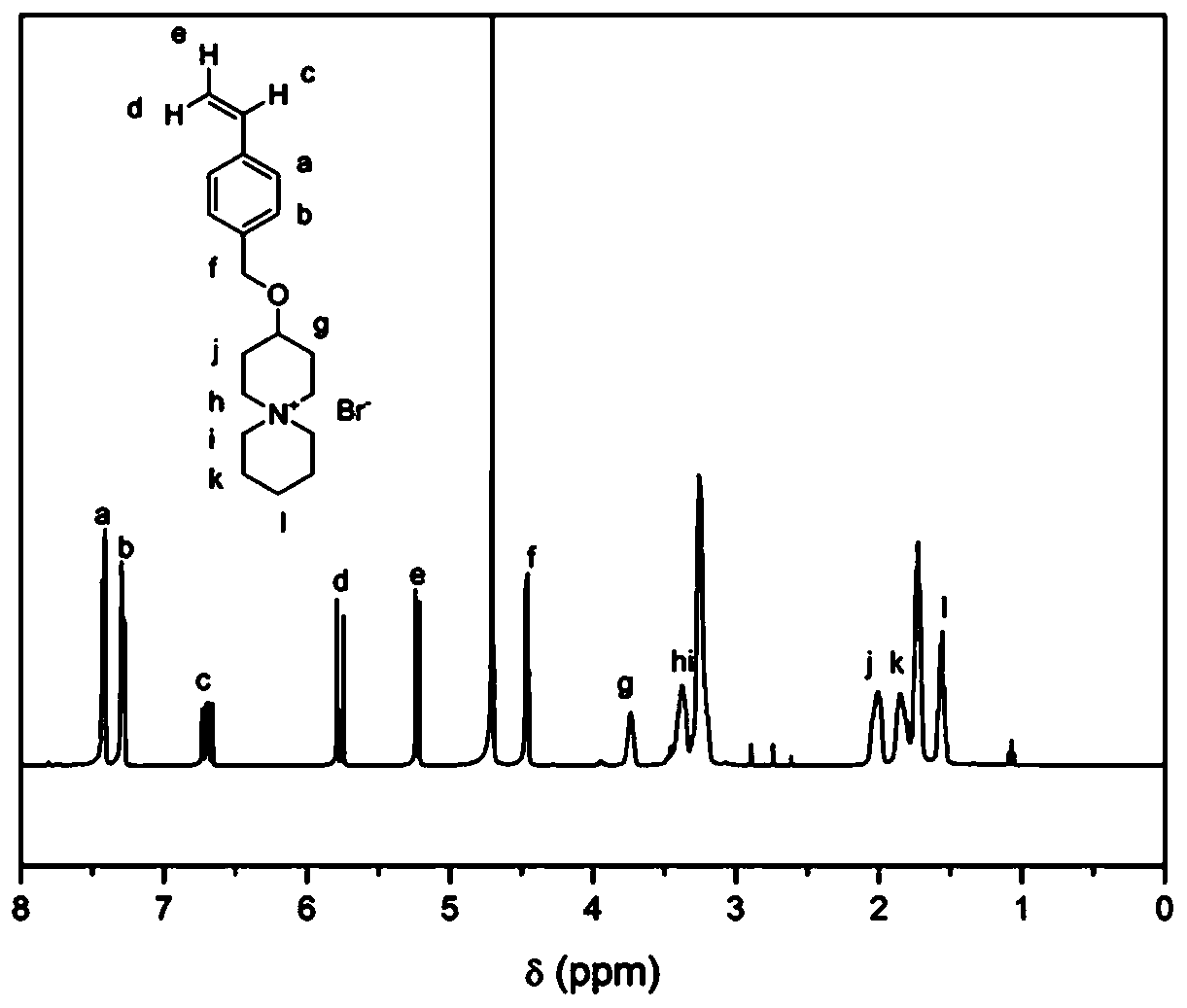

[0025] 2) Synthesis of VBASU

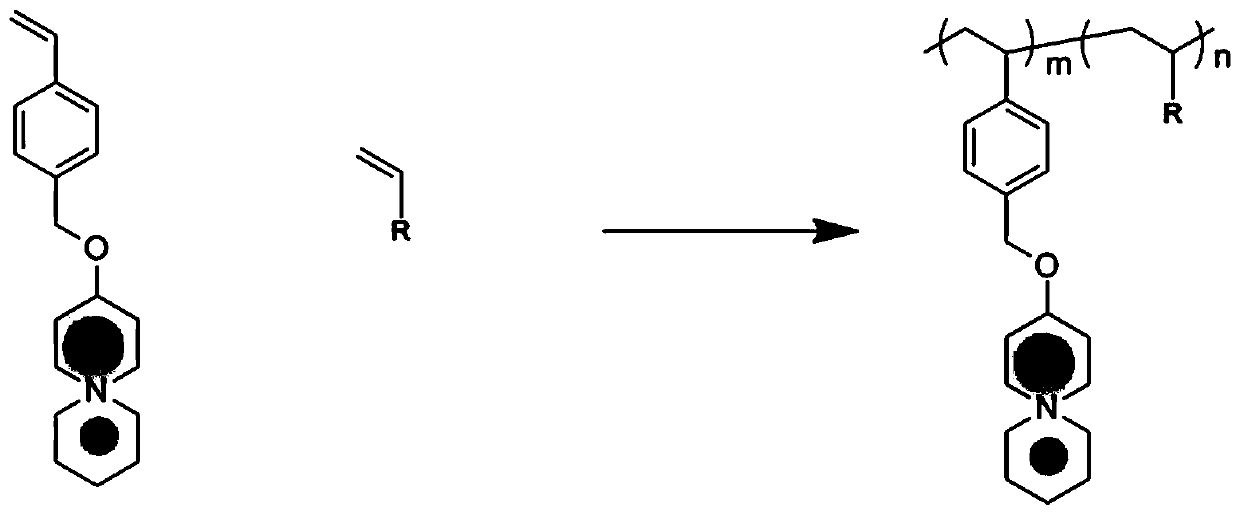

[0026] Weigh 2.5g (10mmol) HOASU and 600mg (15mmol) 60% NaH and dissolve in 50mL DMF, slowly add 1.52g (10mmol) VBC dropwise after no bubbles are generated, react at room temperature for 12h and filter to remove unreacted NaH and generated NaCl, adding 200mL ether to precipitate ...

Embodiment 2

[0030] Synthesis of ASU Modified Polyphenylene Ether

[0031] Weigh 250mg (1mmol) of HOASU and 60mg (1.5mmol) of 60% NaH and dissolve in 5mL of NMP. After no bubbles are generated, slowly add 1.02g of brominated polyphenylene ether solution in NMP, heat to 80°C for 10h and then cool down. Precipitate in acetone to obtain ASU-modified polyphenylene ether. (yield: 90%)

Embodiment 3

[0033] Preparation of anion exchange membrane

[0034] The obtained polymer of the present invention can be made anion exchange membrane by following method: above-mentioned obtained side chain containing ASU polymer is dissolved in NMP and is made into 5wt% homogeneous and transparent solution, is coated on clean flat glass plate with flow-casting method , Heated at 60°C for 24h to remove the solvent, and soaked the glass plate in pure water to peel off the film. The obtained membrane is converted into hydroxide form after ion exchange washing: soak the membrane in 1mol / L NaOH aqueous solution for 24 hours, and replace it with fresh NaOH aqueous solution after 12 hours to fully exchange the ions; the membrane after ion exchange is repeatedly washed with water. Wash at least 10 times, and change fresh water every 2 hours to completely remove residual NaOH in the membrane, and then soak in water for later use.

[0035] The anion-exchange membrane of embodiment 1 gained VBASU a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com