Polymer with asu structure in main chain, preparation method thereof, and anion exchange membrane based on the polymer

An anion exchange membrane and polymer technology, applied in the field of fuel cell and polymer material synthesis, to achieve the effect of wide applicability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

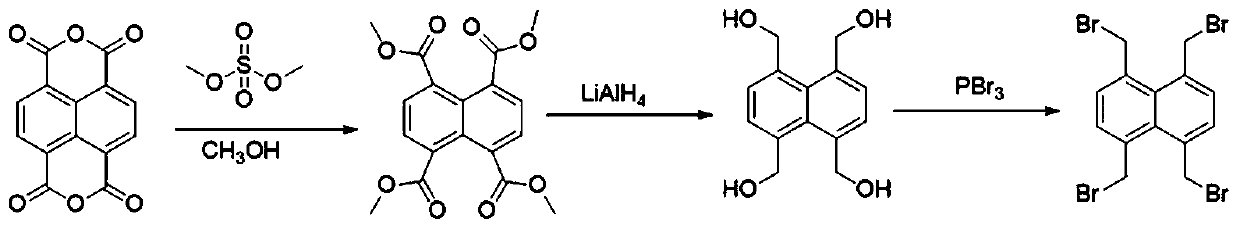

Method used

Image

Examples

Embodiment 1

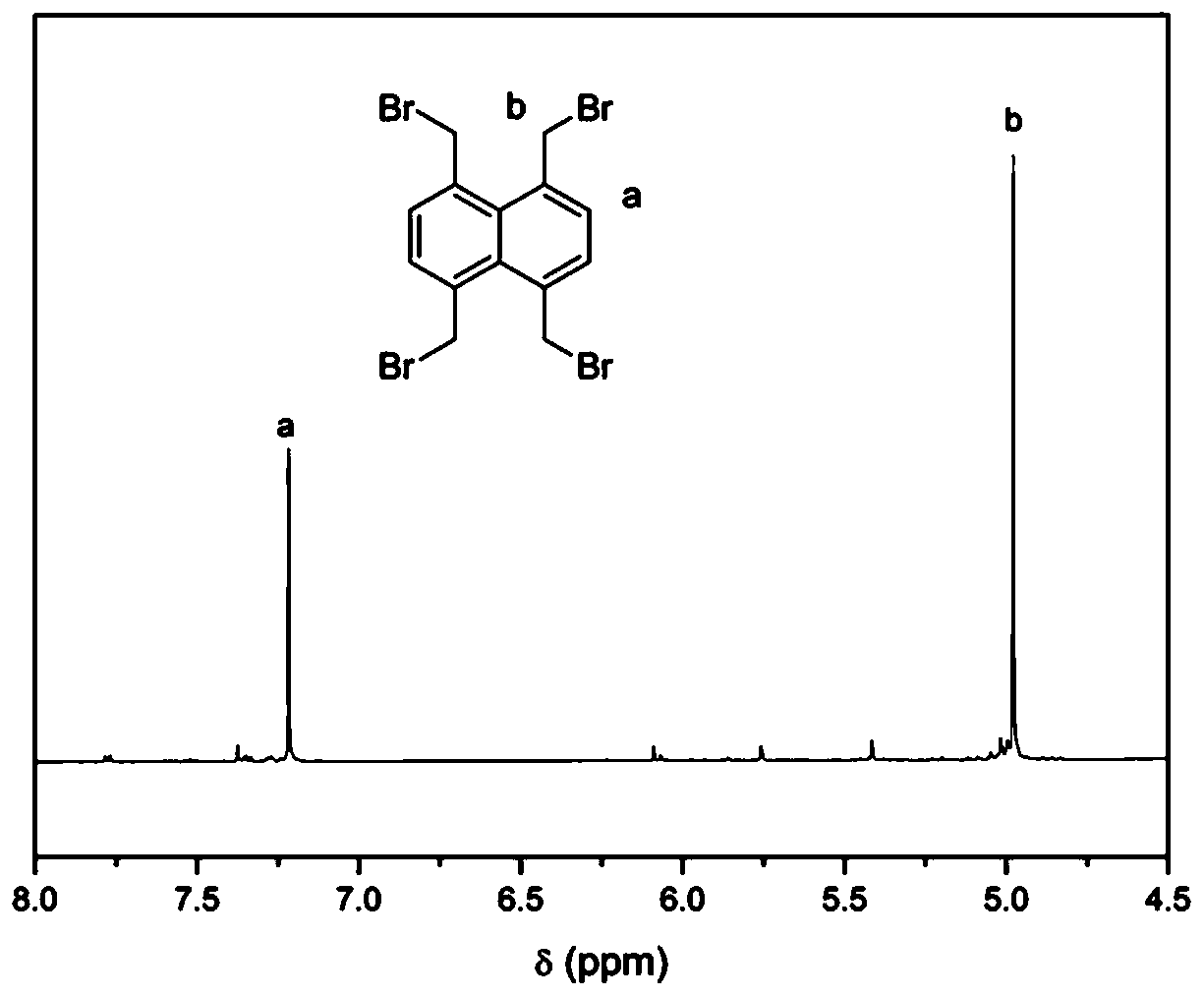

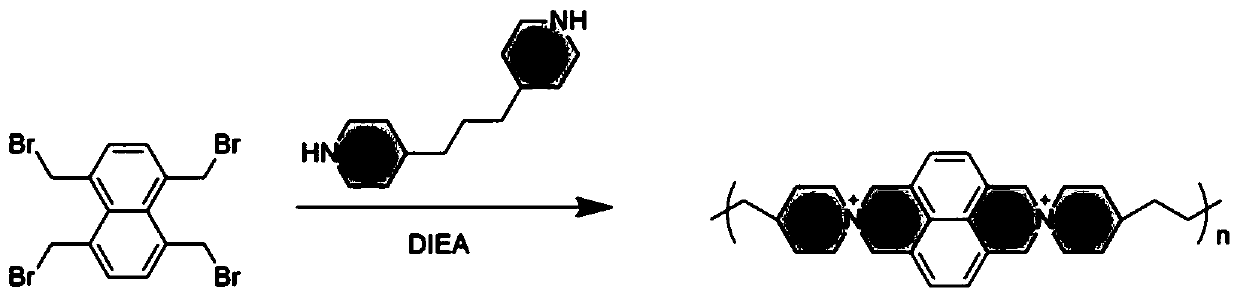

[0023] Polycondensation of 1,4,5,8-tetrabromomethylnaphthalene and 1,3-bis(4-piperidinyl)propane

[0024] 250mg (0.5mmol) 1,4,5,8-tetrabromomethylnaphthalene was dissolved in 7mL DMF, and then 290mg DIPEA, 105mg (0.5mmol) 1,3-bis(4-piperidinyl)propane DMF were added Mixed solution with water (1mL / 1.5mL). After reacting at 60°C for 10 hours, it was cooled, dropped into 50 mL of acetone for precipitation, filtered off with suction, and dried to obtain the product, which was verified by nuclear magnetism.

Embodiment 2

[0026] Polycondensation of 1,4,5,8-tetrabromomethylnaphthalene and 4,4'-bipiperidine

[0027] 500mg (1mmol) 1,4,5,8-tetrabromomethylnaphthalene was dissolved in 15mL DMF, then 903mg DIPEA, 241mg (1mmol) 1,3-bis(4-piperidinyl)propane DMF and water were added The mixed solution (2mL / 3mL). After reacting at 60°C for 10 hours, it was cooled, dropped into 100 mL of acetone for precipitation, filtered with suction, and dried to obtain the product with a yield of 95%.

Embodiment 3

[0029] Polycondensation of 3,4,9,10-tetrachloromethylperylene with 1,3-bis(4-piperidinyl)propane

[0030] 223mg (0.5mmol) 3,4,9,10-tetrachloromethylperylene was dissolved in 8mL NMP, and then 290mg DIPEA, 105mg (1mmol) 1,3-bis(4-piperidinyl)propane NMP and Water mixed solution (1mL / 1.5mL). After reacting at 60°C for 10 hours, it was cooled, dropped into 100 mL of acetone for precipitation, filtered with suction, and dried to obtain the product with a yield of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com