Spring operating mechanism closing spring residual energy absorption device

A closing spring and operating mechanism technology, applied in high-voltage/high-current switches, high-voltage air circuit breakers, electrical components, etc., can solve the problem of irregular swing angle, poor stability of closing spring energy storage, and difficulty in closing residual energy. Absorption and other problems, to achieve the effect of long service life, reasonable structure design and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

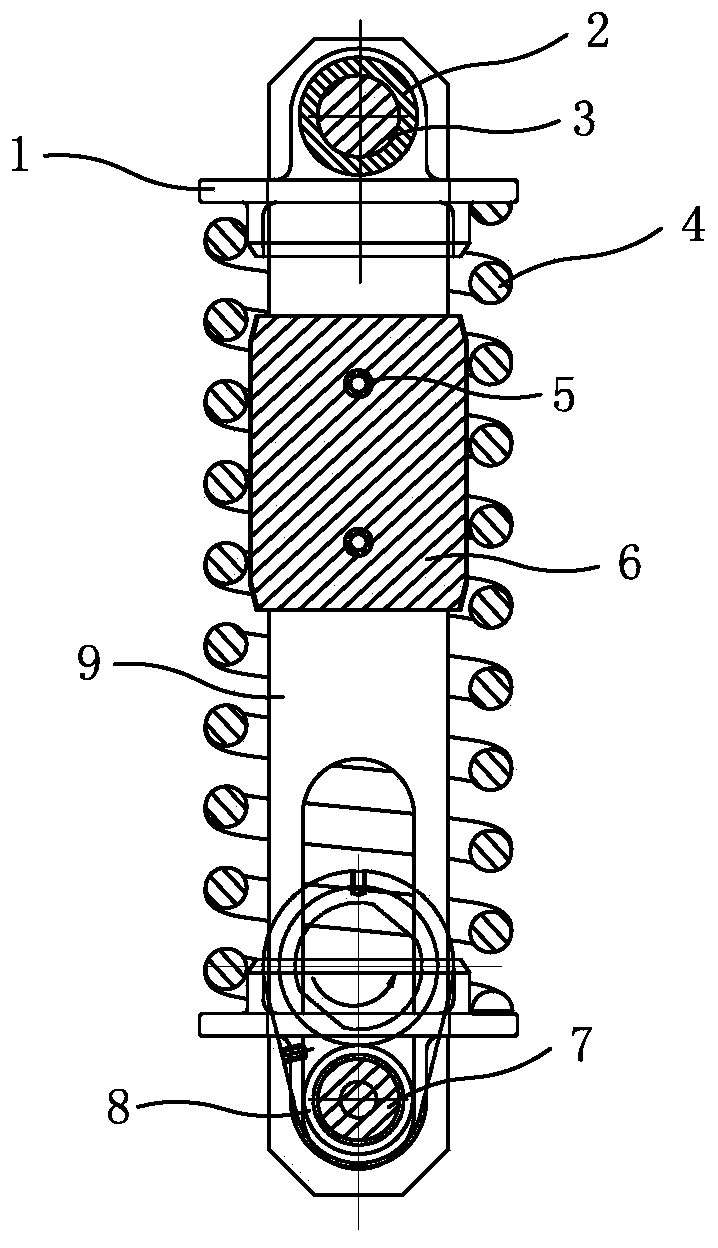

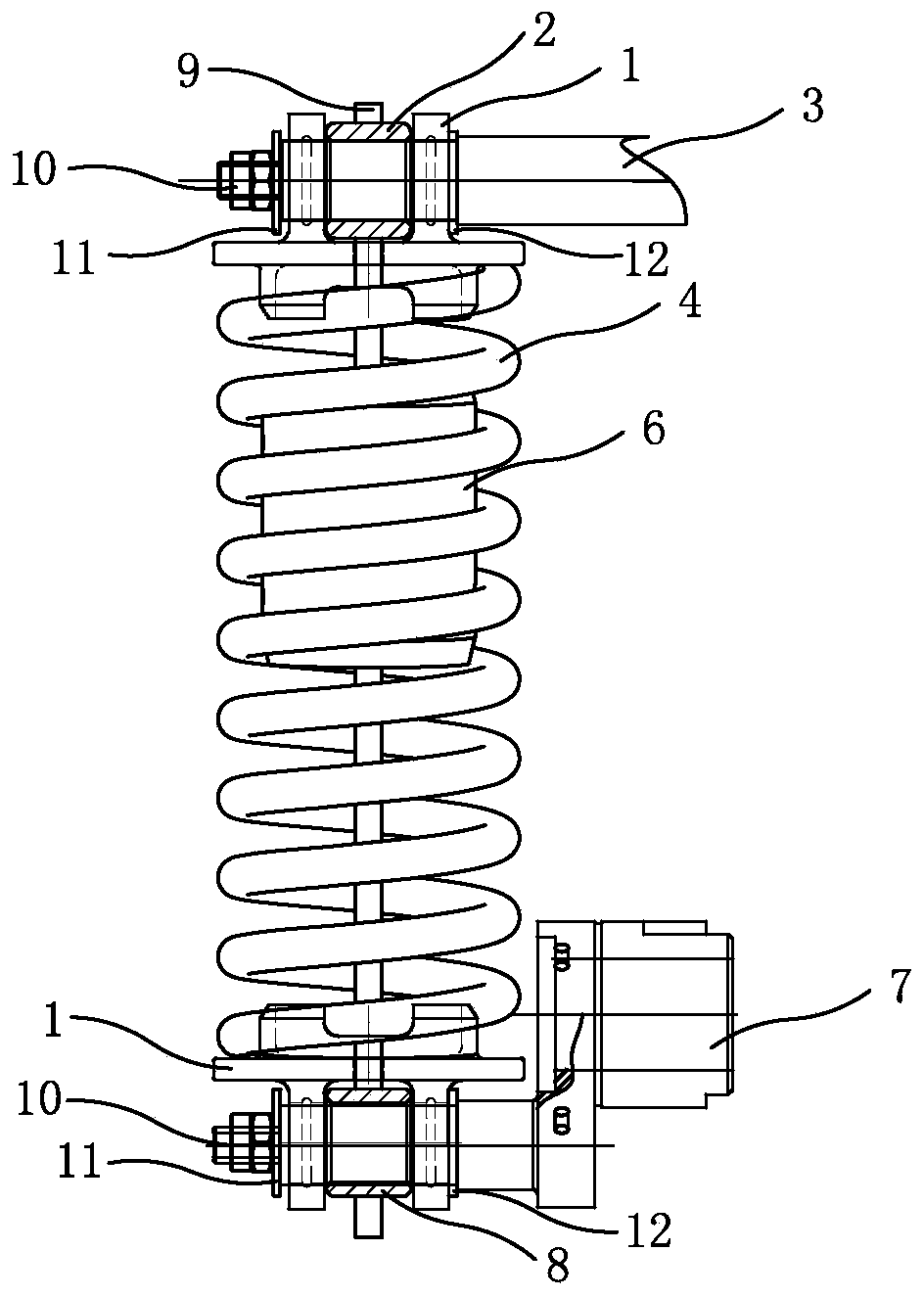

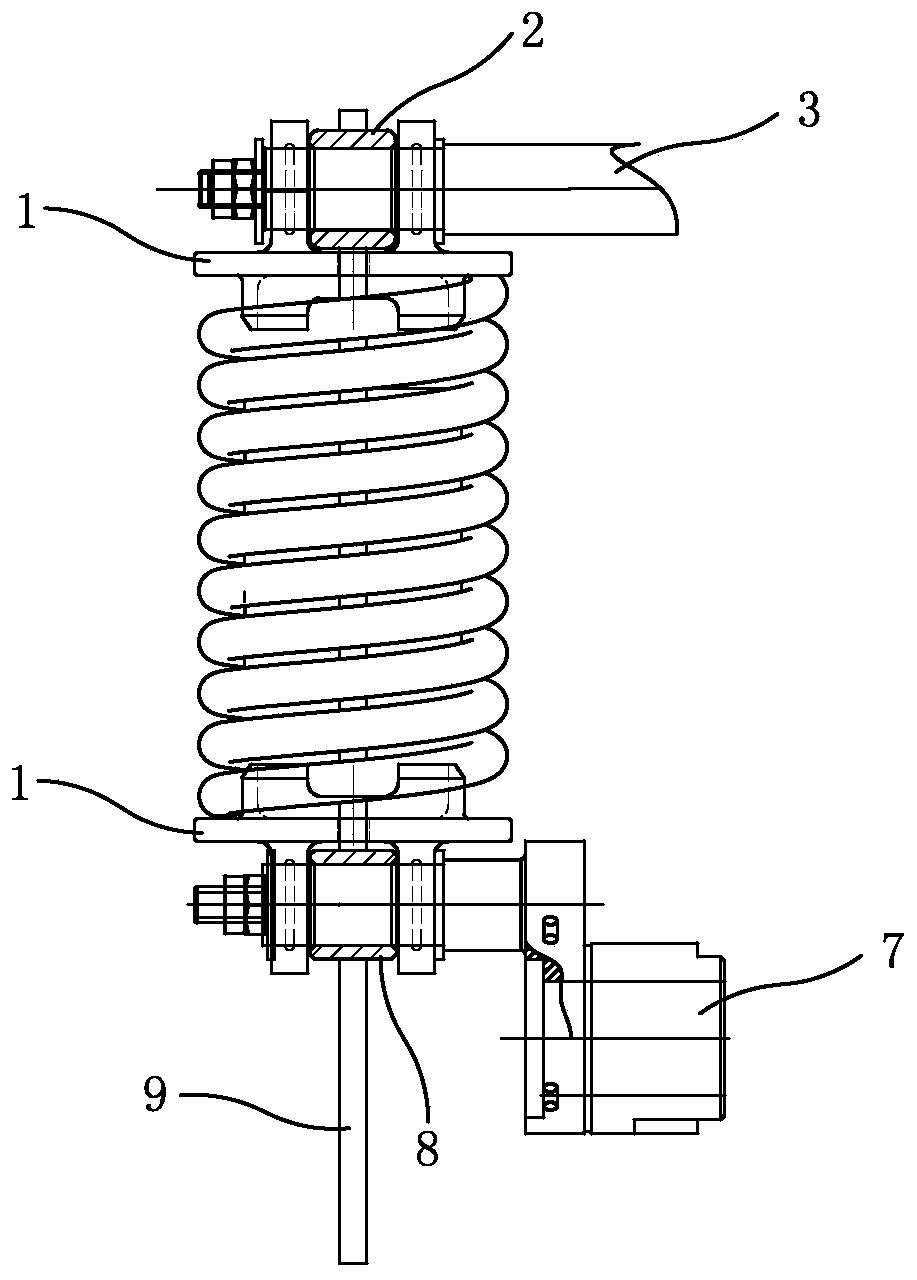

[0016] Now in conjunction with the accompanying drawings, the structure of the present invention will be further described. Such as Figure 1-Figure 5 As shown, the device includes spring seat 1, roller sleeve 2, fixed hanging spring shaft 3, closing spring 4, elastic cylindrical pin 5, buffer sleeve 6, energy storage crank arm 7, guide roller 8, guide plate 9, hexagonal locking The nut 10, the guide plate and the buffer sleeve are combined into a whole through elastic cylindrical pins. The closing springs at both ends of the guide plate are respectively limited to the spring seat, and the spring seat is respectively provided with a roller sleeve and a guide roller. The spring seat at the end of the roller sleeve, the guide plate and the fixed hanger The spring shaft is connected, and the spring seat and the guide plate at the end of the guide roller are connected with one end of the energy storage arm. One end swings as the center of rotation to realize telescoping. Simulta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com