Battery module bottom limiting mechanism of battery compartment

A battery module and limiting mechanism technology, applied in battery pack components, battery assembly machines, secondary battery manufacturing, etc., can solve problems such as affecting battery installation efficiency, time-consuming and laborious replacement of battery modules, and saving time in positioning. Labor saving, ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

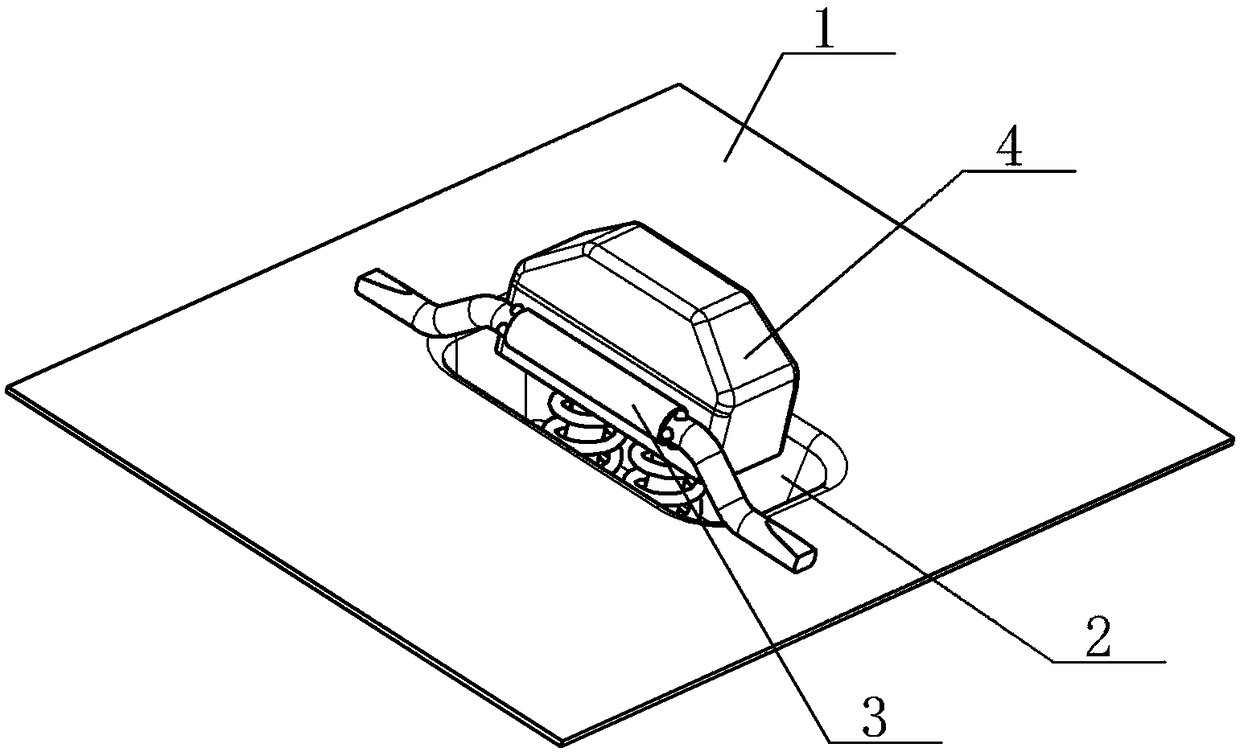

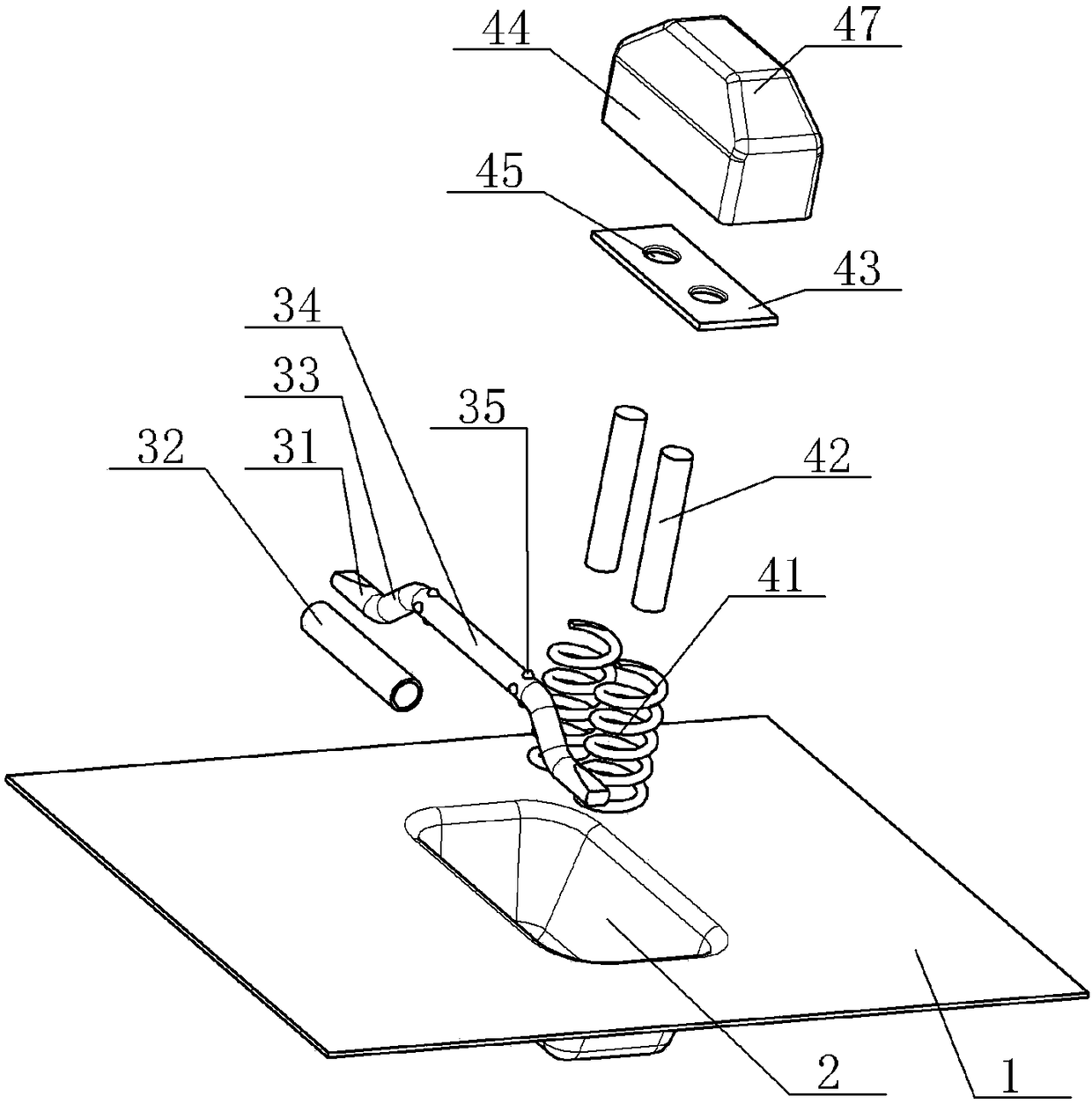

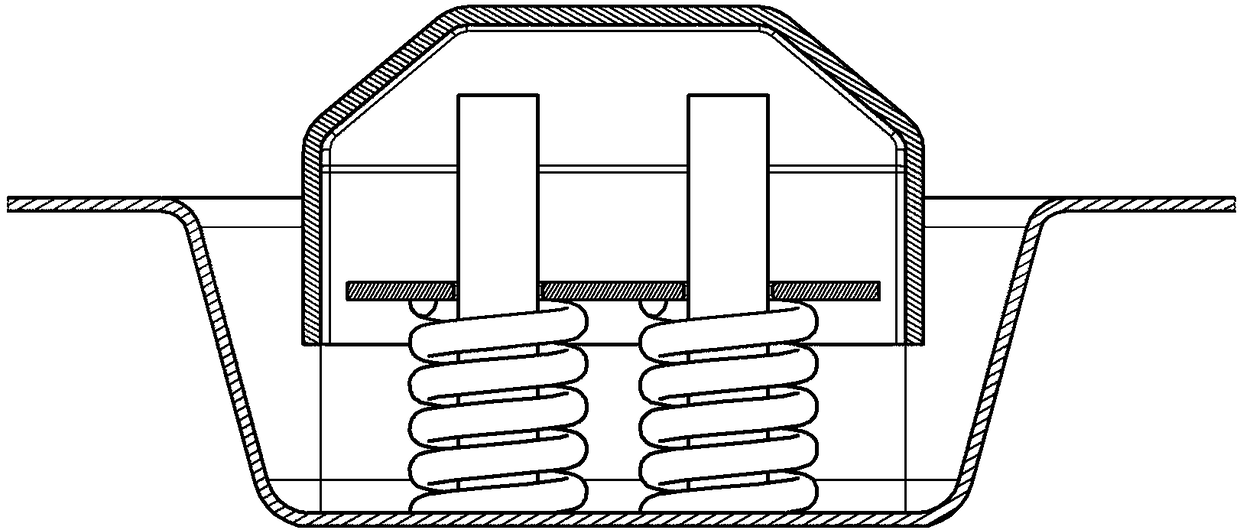

[0023] A limit mechanism at the bottom of the battery module of the battery compartment, see Figure 1-Figure 6 : It includes the lower groove 2 on the bottom plate 1, the collar assembly 3, the pressure spring mechanism assembly 4, the collar assembly 3 includes the collar shaft 31, the collar 32, and the collar shaft 31 includes the middle bending protrusion 33. The collar 32 is set on the straight section 34 of the middle bending protrusion 33, and the two ends of the collar shaft 31 are respectively welded to connect to the corresponding positions of the bottom plate 1. The spring pressing mechanism assembly 4 includes a linear spring 41 and a spring limit post 42 , limit plate 43, limit frame 44, the bottom of each spring limit post 42 is welded to the bottom of the lower groove 2, and each spring limit post 42 is covered with a linear spring 41, and the lower end of the linear spring 41 is fixed At the bottom of the lower groove 2, the upper end of the linear spring 41 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com