Micro-fluidic chip capable of realizing flow rate relying avoidance of liquid drip dimension

A technology of microfluidic chip and droplet size, which is applied in the direction of laboratory containers, laboratory utensils, chemical instruments and methods, etc., and can solve the problems of limited detection and reaction applications, unstable microfluidic chip performance, microfluidic Control technology is difficult to apply and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

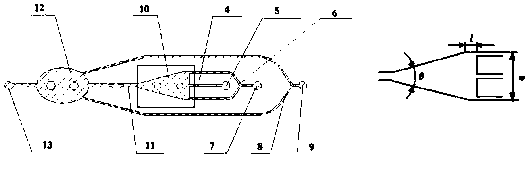

[0024] The working process and effect of inventing a microfluidic chip capable of realizing droplet size independent of flow will be described in detail below in conjunction with the structural drawings.

[0025] The specific working process of this chip is as follows: the discrete phase liquid flows in from the discrete phase inlet 5, the continuous phase liquid flows in from the continuous phase inlet 7, and the two meet in the droplet generation chamber 10, and the discrete phase liquid breaks to generate droplets and together with the continuous phase It flows downstream, enters the droplet observation cavity 12 through the main channel, and finally flows out of the chip through the outlet 13 .

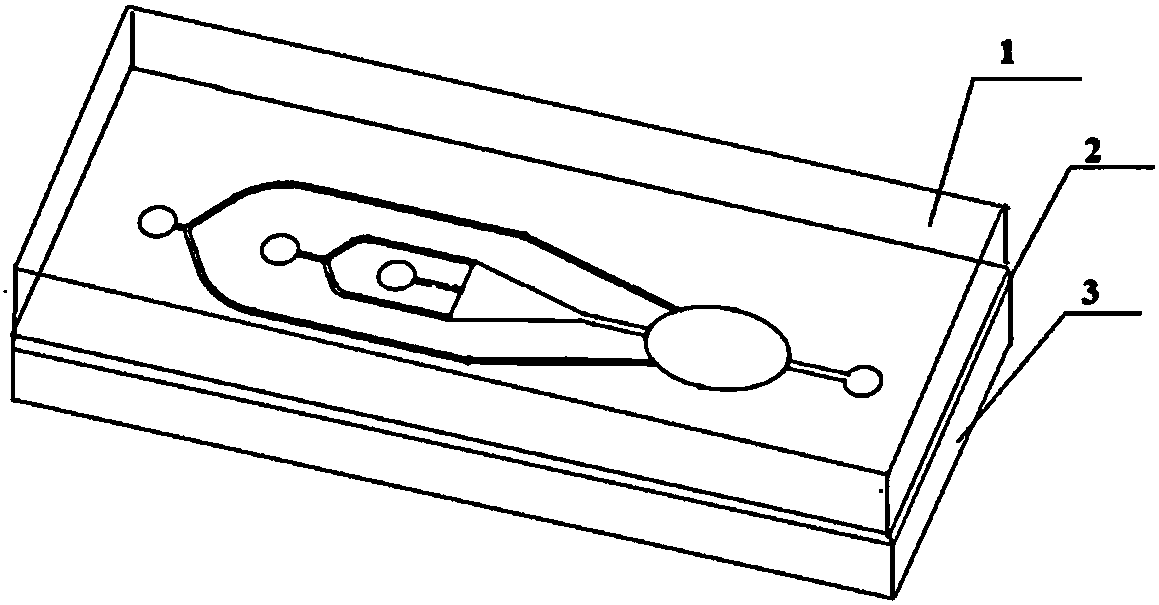

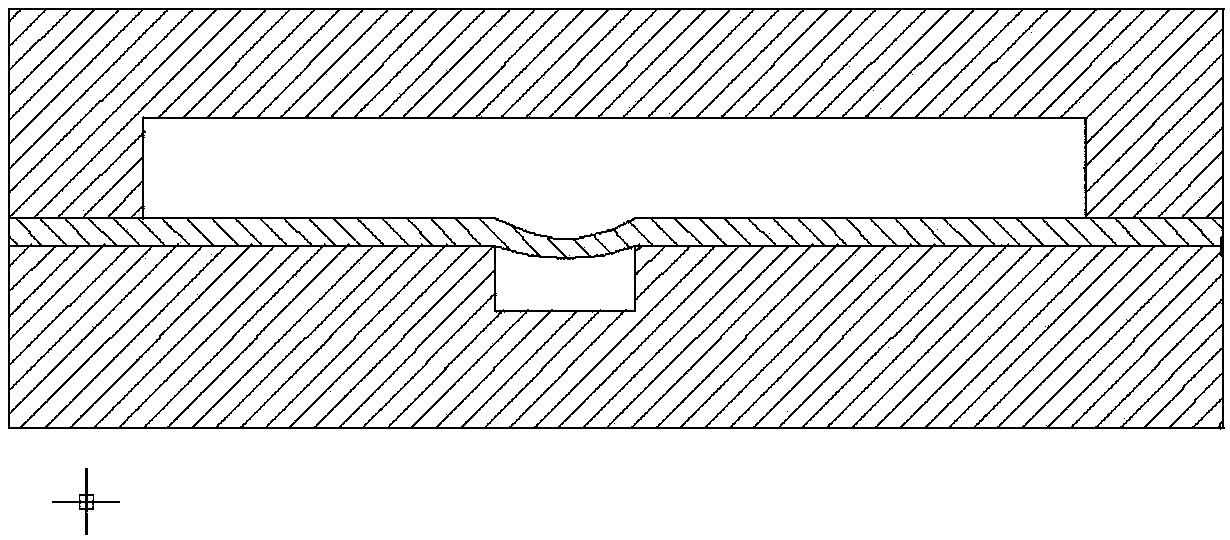

[0026] figure 1 It is a three-dimensional general outline schematic diagram of a microfluidic chip capable of realizing droplet size independent of flow rate in the present invention. figure 2 , image 3 It is a schematic diagram of the working process. There are nine microchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com