Patents

Literature

49 results about "Taguchi methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

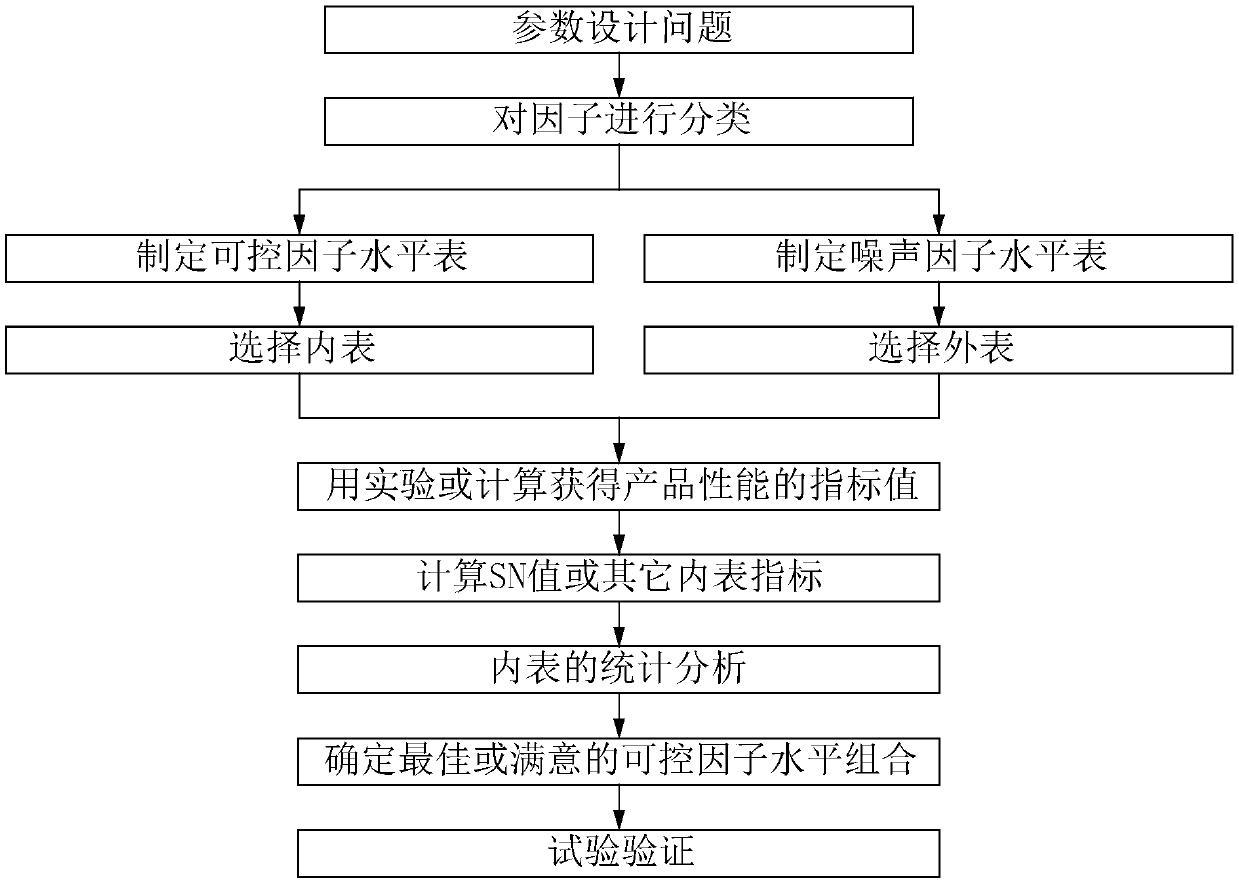

Taguchi methods (Japanese: タグチメソッド) are statistical methods, or sometimes called robust design methods, developed by Genichi Taguchi to improve the quality of manufactured goods, and more recently also applied to engineering,biotechnology, marketing and advertising. Professional statisticians have welcomed the goals and improvements brought about by Taguchi methods, particularly by Taguchi's development of designs for studying variation, but have criticized the inefficiency of some of Taguchi's proposals.

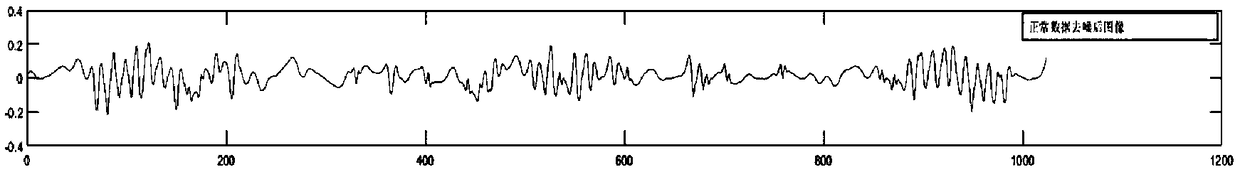

Mechanical wearing part performance assessment and prediction method based on EMD (empirical mode decomposition)-SVD (singular value decomposition) and MTS (Mahalanobis-Taguchi system)

InactiveCN103674511AAvoid error-prone problemsSave math featuresMachine part testingSingular value decompositionFeature vector

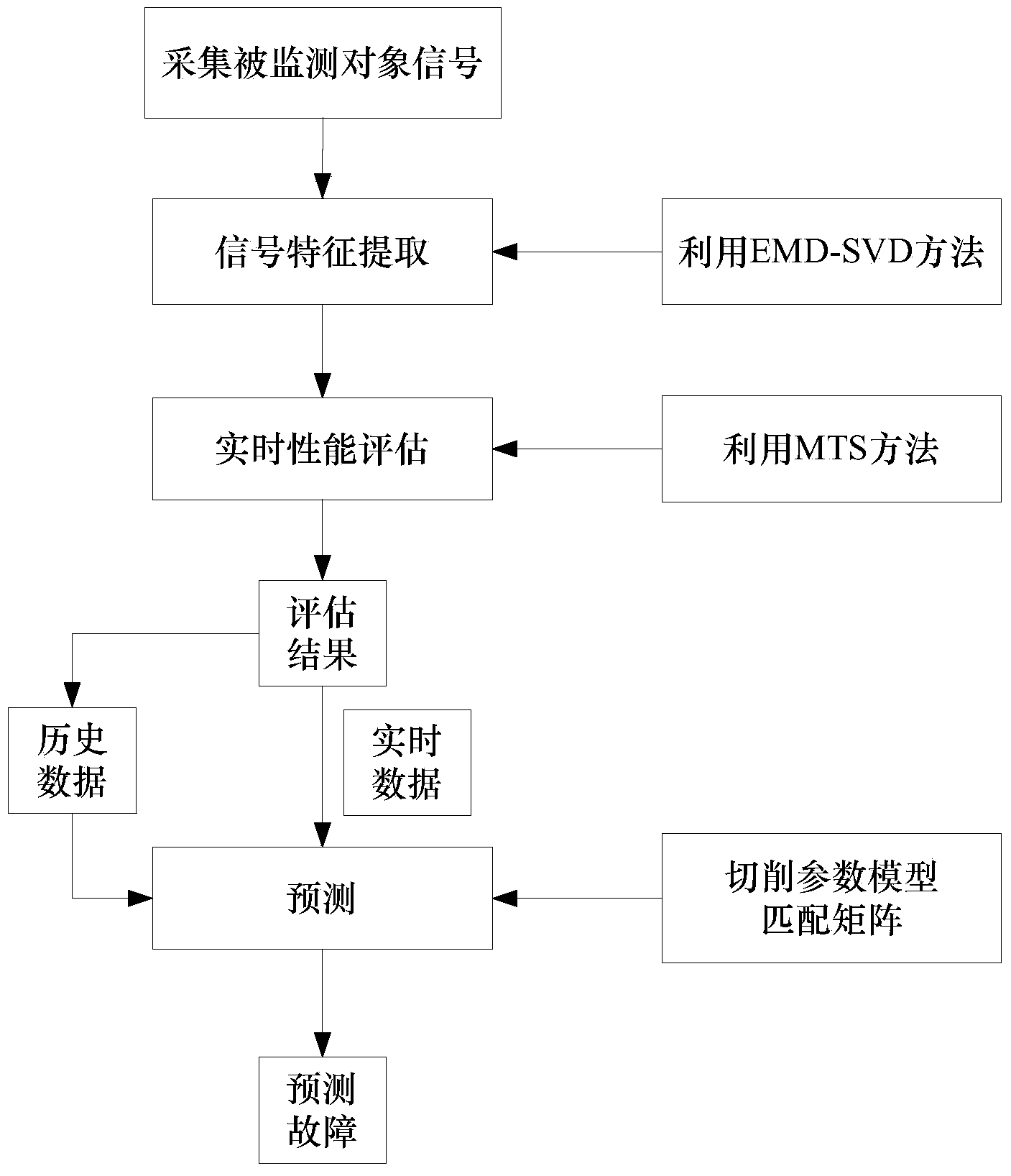

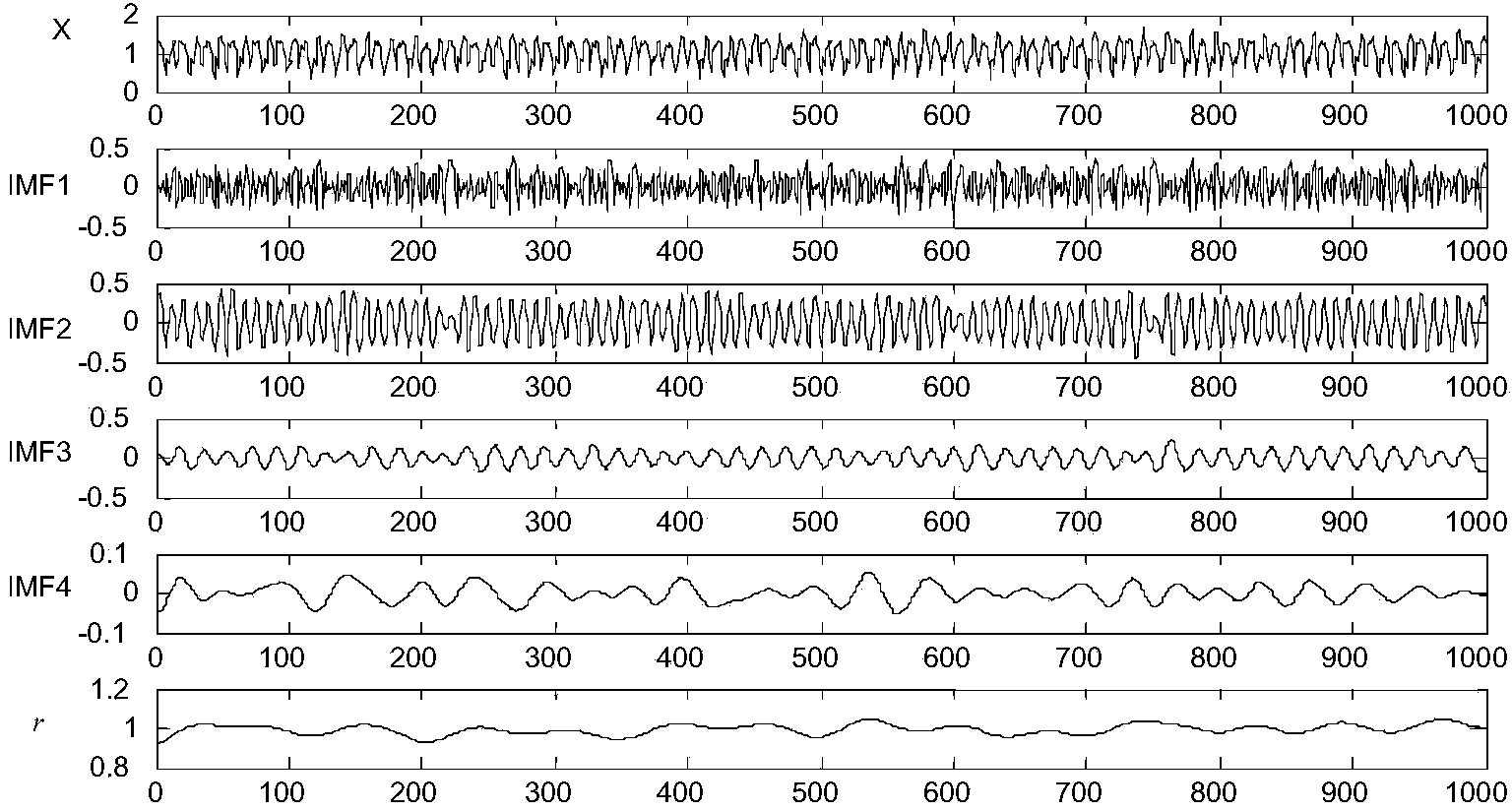

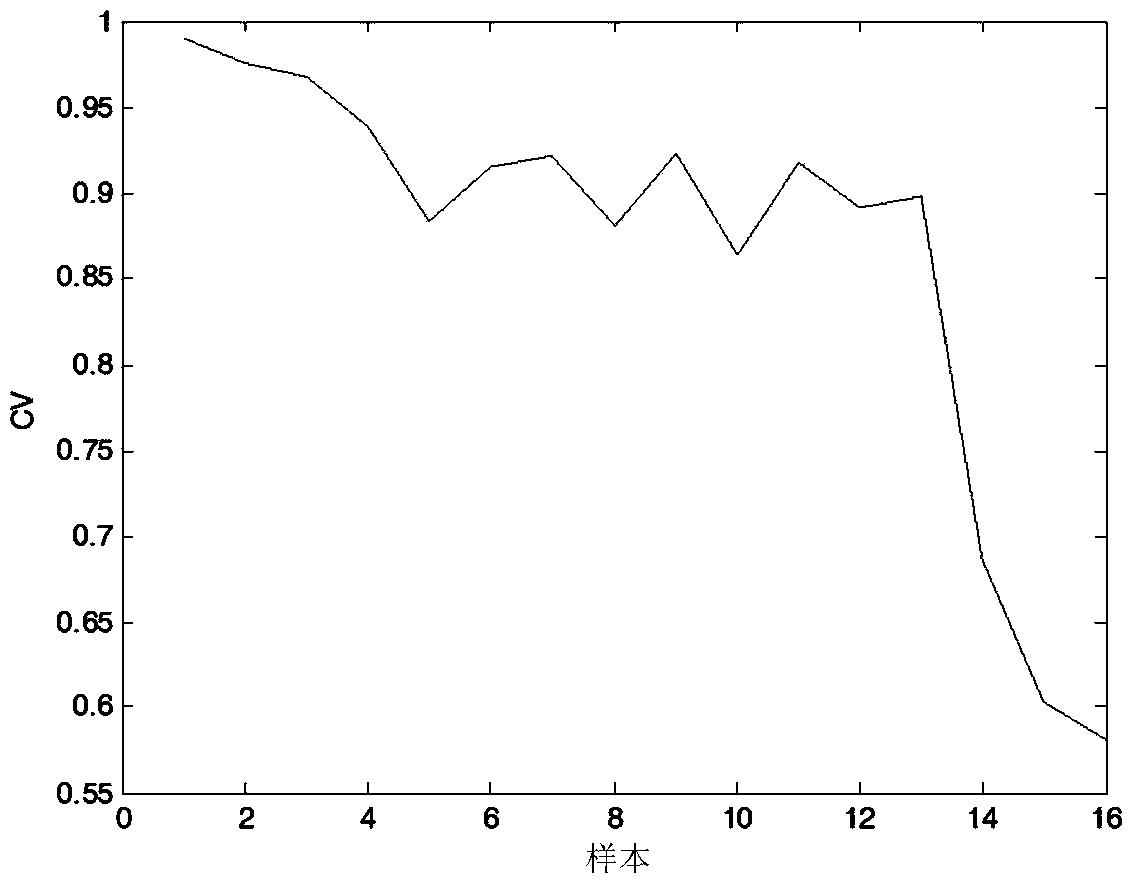

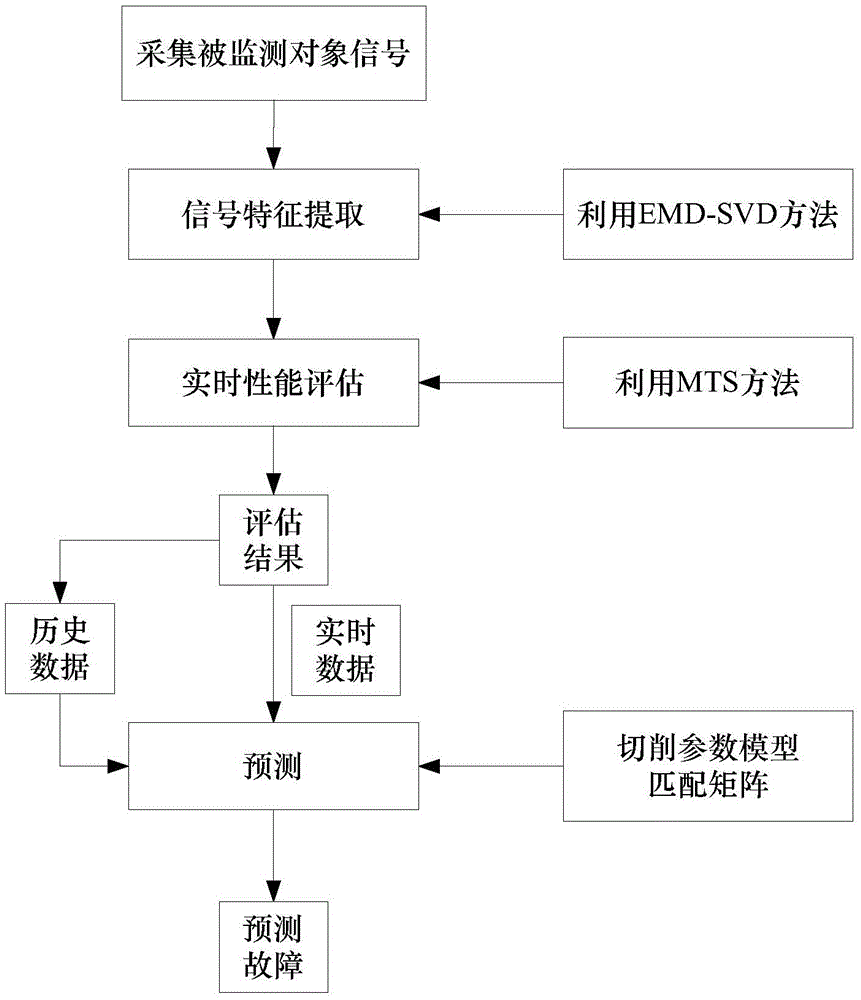

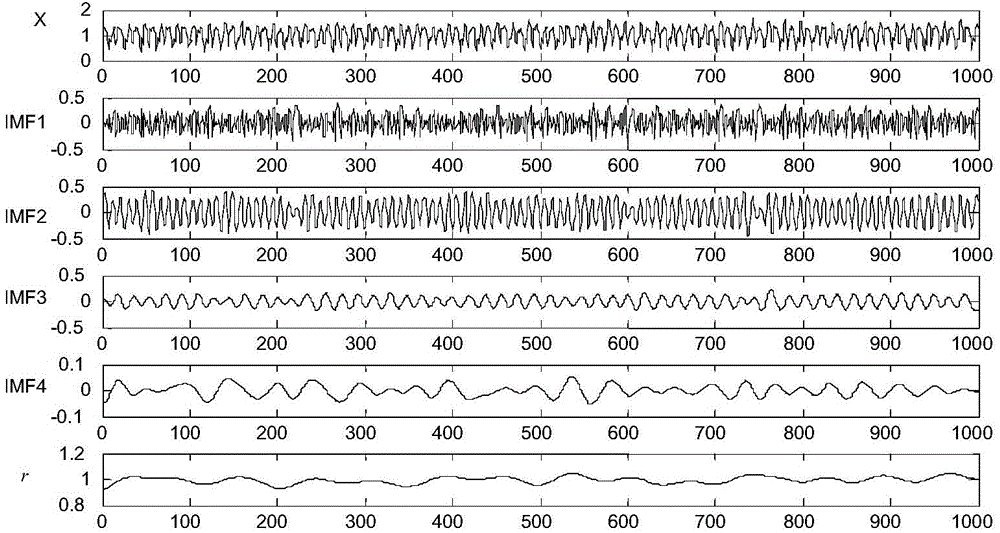

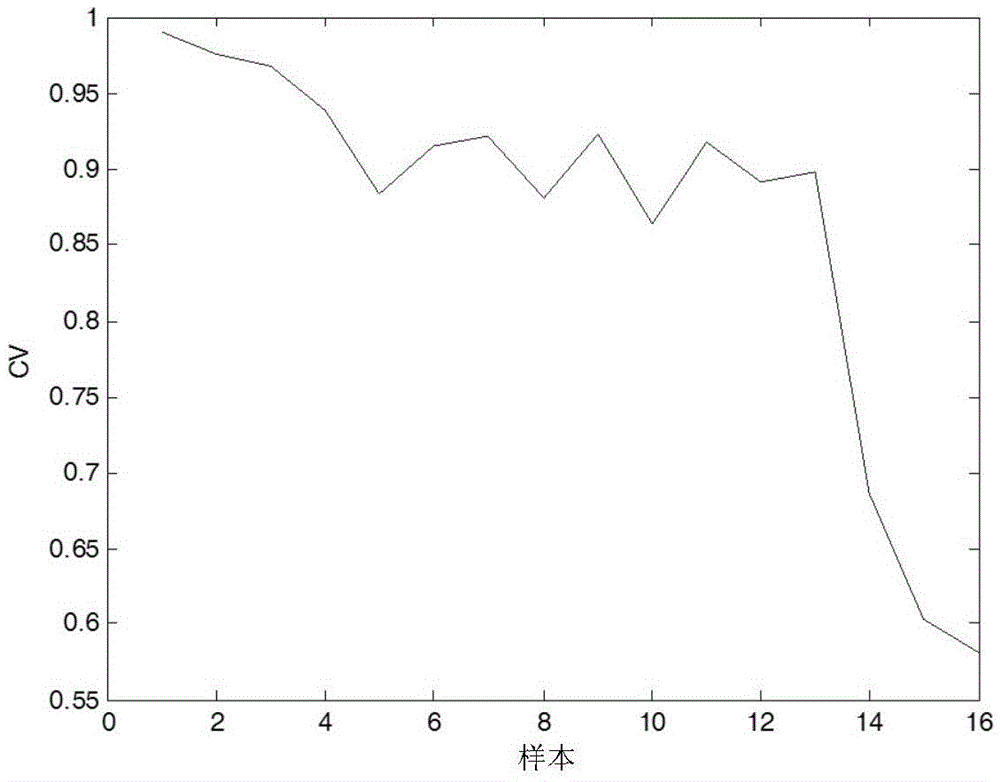

The invention provides a mechanical wearing part performance assessment and prediction method based on based on EMD (empirical mode decomposition)-SVD (singular value decomposition) and an MTS (Mahalanobis-Taguchi system), and belongs to the technical field of mechanical wearing part fault diagnosis. The method comprises: first of all, performing noise reduction processing on acquired signals of a monitored object, then performing EMD on the signals, selecting effective IMF (intrinsic mode function) components and residual functions to form an initial matrix, performing SVD on the initial matrix, and performing normalization processing on obtained characteristic values to obtain characteristic vectors; then using an MTS method to calculate an MD (Mahalanobis Distance), and using a Taguchi method to perform optimization and reduction on the characteristic vectors; and converting the MD into a confidence value, performing assessment on the performance of mechanical wearing parts through tracking the trend of the confidence value, and performing prediction on a fault through a correlation module or a matching matrix between the confidence value and conditions of the monitored object. The method provided by the invention avoids the problem of easily occurring errors when a conventional method is used for processing non-linear non-stationary signals, and reduces fault generation probability, thereby being suitable for industrial real-time monitoring.

Owner:BEIHANG UNIV

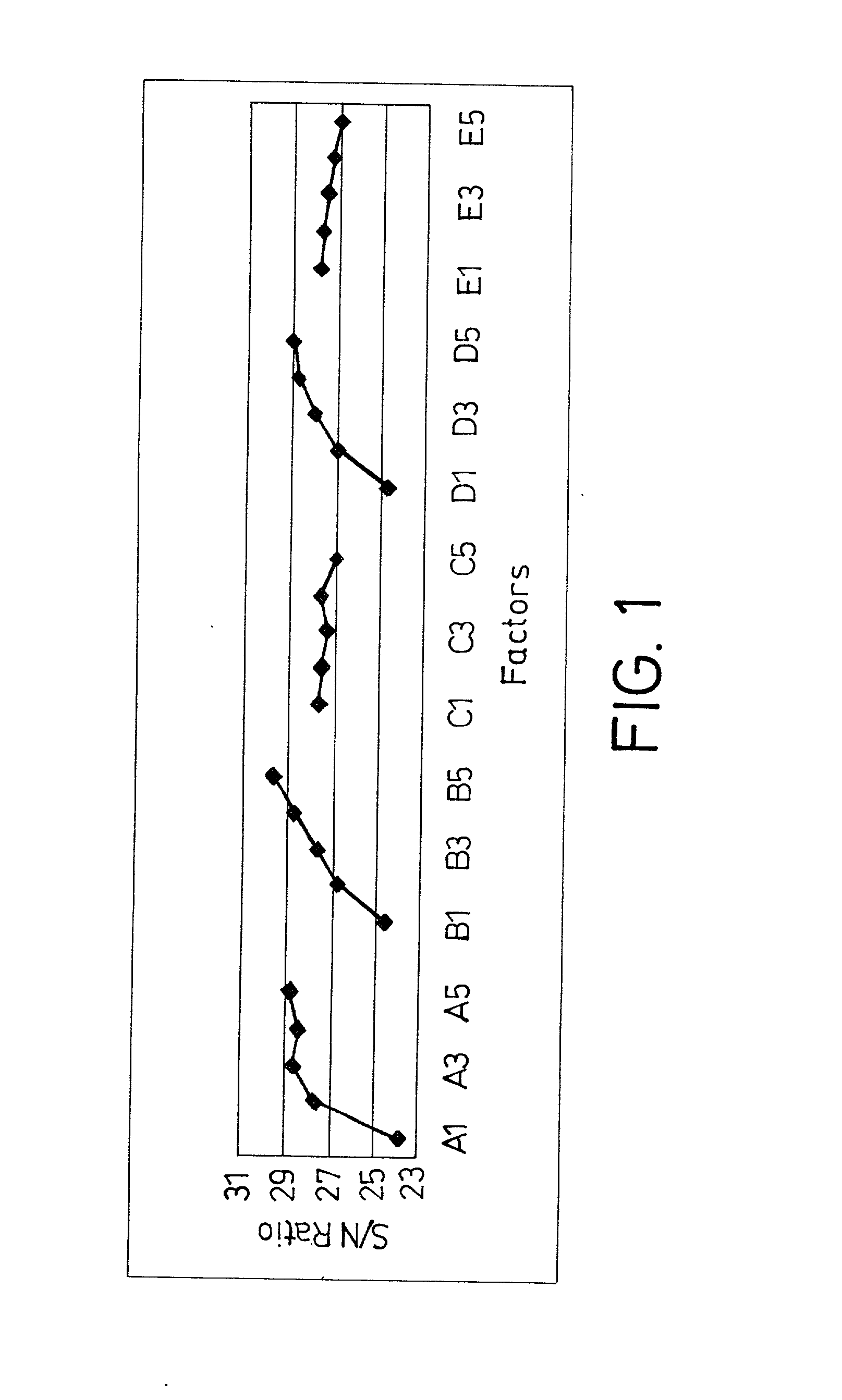

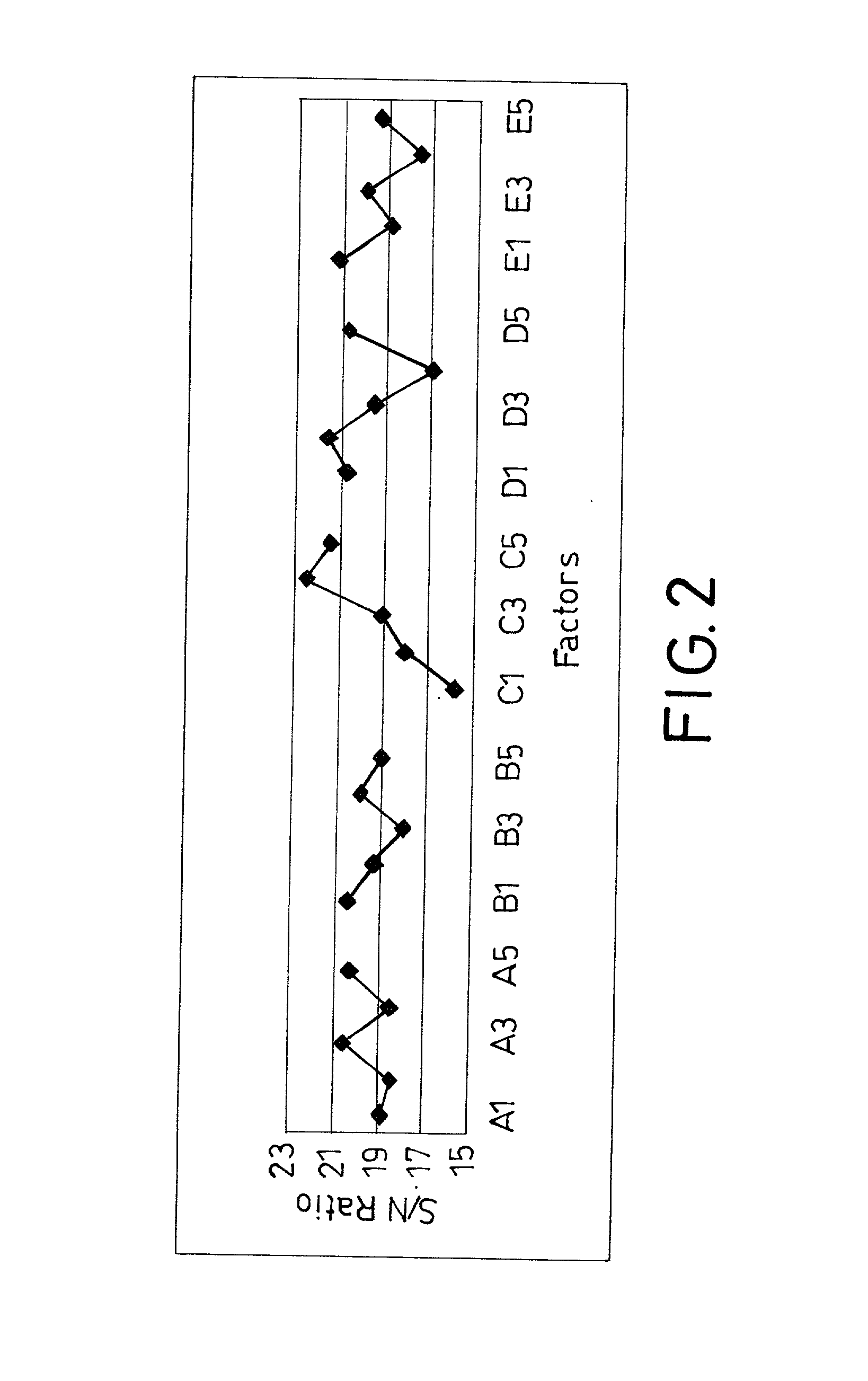

Efficient energy-saving optimizing method for numerical control milling processing process parameters based on Taguchi method

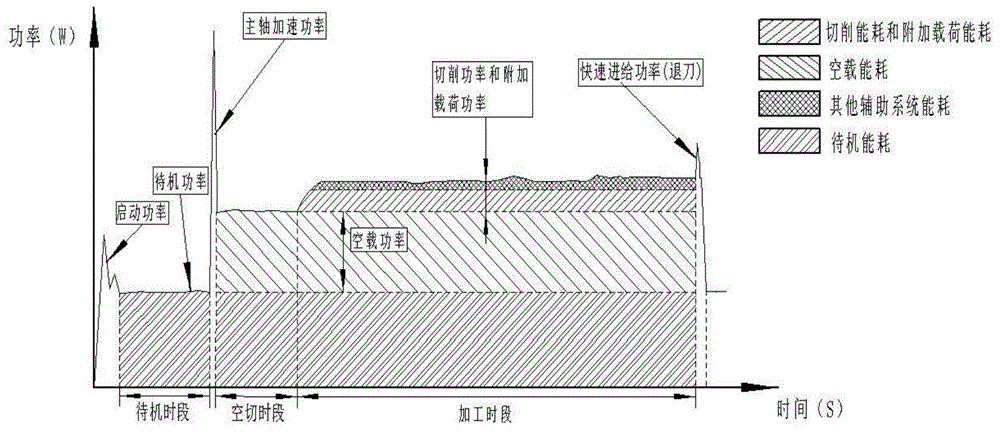

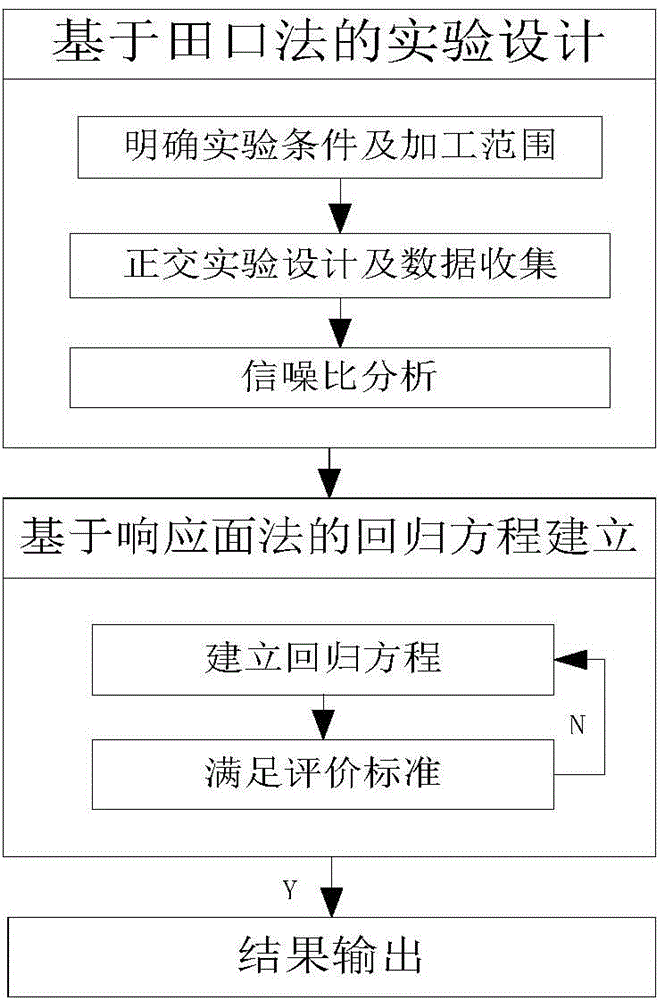

The invention discloses an efficient energy-saving optimizing method for numerical control milling processing process parameters based on a Taguchi method. The efficient energy-saving optimizing method comprises the following steps: analyzing characteristics of a numerical control milling processing process energy consumption time interval and establishing a numerical control milling processing energy efficiency function; designing orthogonal experiment by applying an orthogonal table in the Taguchi method, and adopting signal to noise ratio evaluation to obtain an interference relationship between process parameters and processing time as well as specific energy consumption; obtaining a regression equation of each target by adopting a response surface process, and establishing an efficient energy-saving multi-target optimizing model for numerical control milling processing process parameters; and searching out Paretro optimal solution through a particle swarm optimization. Correlation relationship of specific energy, processing time and process parameters in the processing process is analyzed through experimental data and algorithm optimizing results, so that a complex coupling mechanism between energy consumption efficiency and process parameters is disclosed in the numerical control milling processing process.

Owner:CHONGQING UNIV

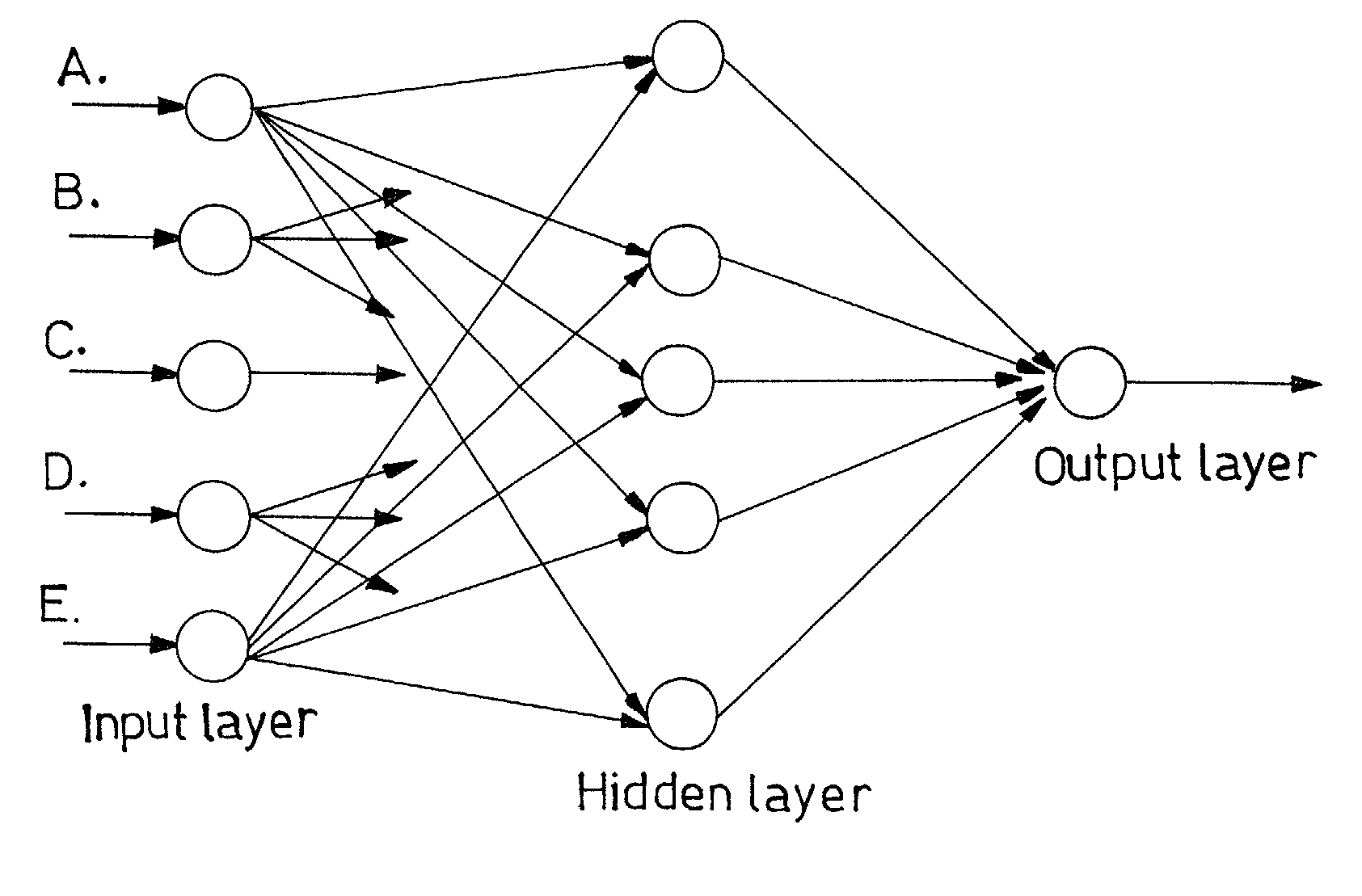

Short-term traffic flow prediction method based on nerve network combination model

InactiveCN105701571AImprove forecast accuracyReduce forecast errorForecastingCharacter and pattern recognitionCluster algorithmNerve network

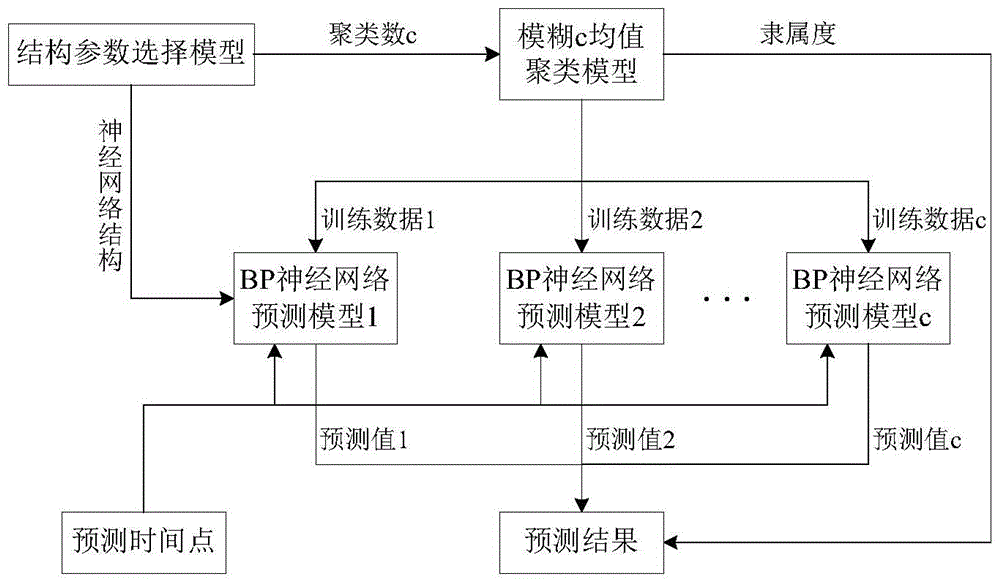

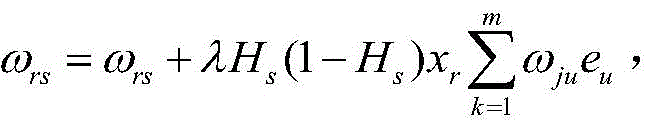

The invention provides a short-term traffic flow prediction method based on a nerve network combination model. The method is used to construct a counterpropagation nerve network combination prediction model and the short-term traffic flow prediction method is provided based on the model. Aiming at a characteristic of a traffic flow, a fuzzy C mean value clustering algorithm is used to cluster the traffic flow. For bunch generated through clustering, a counterpropagation nerve network prediction model is constructed. According to grade of membership, a weighted sum of prediction model prediction results is calculated and is taken as a final prediction result. In order to increase prediction precision, a taguchi method is used to carry out test designing so as to test influences of different structure parameters on prediction model prediction precision, and an optimum structure parameter is used as an initial structure of the prediction model. By using the method in the invention, the prediction precision of the short-term traffic flow can be effectively increased, an influence of a noise on the prediction precision in training data is reduced and operation time is reasonable.

Owner:NANJING UNIV OF POSTS & TELECOMM

Method for determining efficiently parameters in chemical-mechanical polishing (CMP)

InactiveUS6564116B2Semiconductor/solid-state device manufacturingSpecial data processing applicationsMaterial removalEngineering

Owner:NATIONAL CHUNG HSING UNIVERSITY

Method for determining efficiently parameters in chemical-mechanical polishing (CMP)

InactiveUS20030028279A1Semiconductor/solid-state device manufacturingSpecial data processing applicationsMaterial removalEngineering

A method of determining efficiently parameters in chemical-mechanical polishing, especially a method includes a Neural-Taguchi method to seek the best parameter set to increase the quantity of output. This invention involves a time parameter to achieve end-point detection on line during the CMP procedure and also completes a maximum material removal rate (MRR) and a minimum within wafer non-uniformity (WIWNU) at the same time.

Owner:NATIONAL CHUNG HSING UNIVERSITY

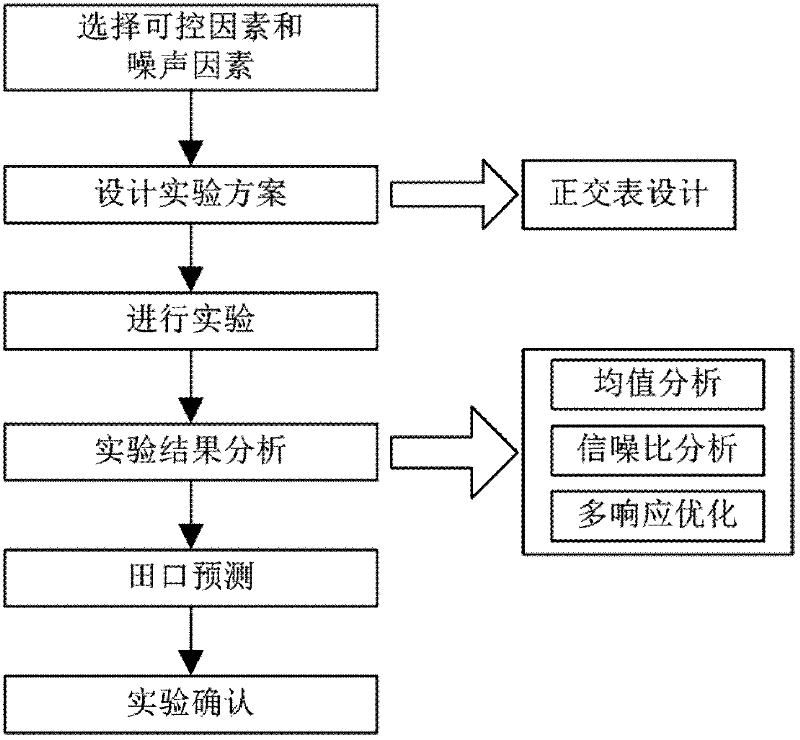

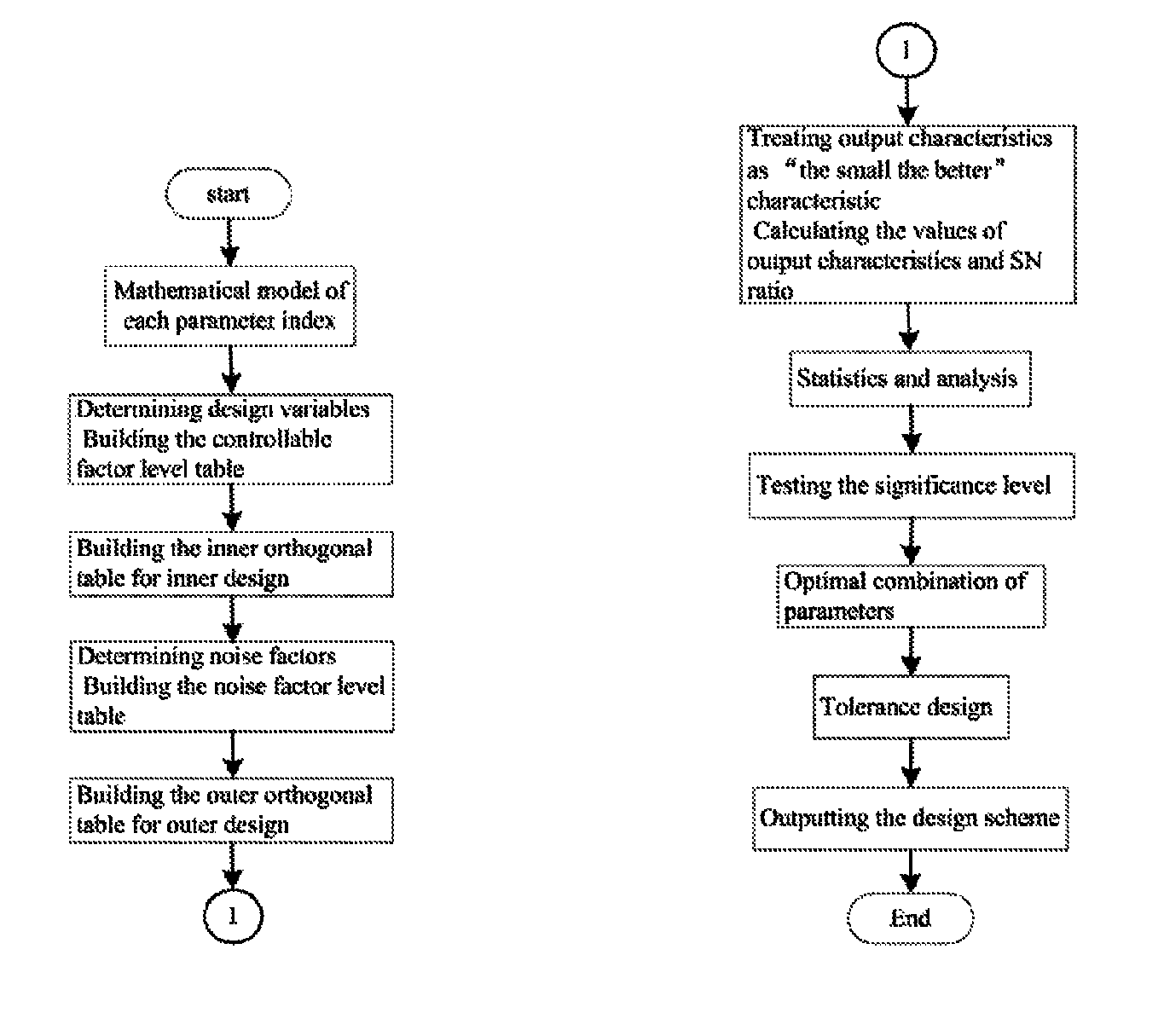

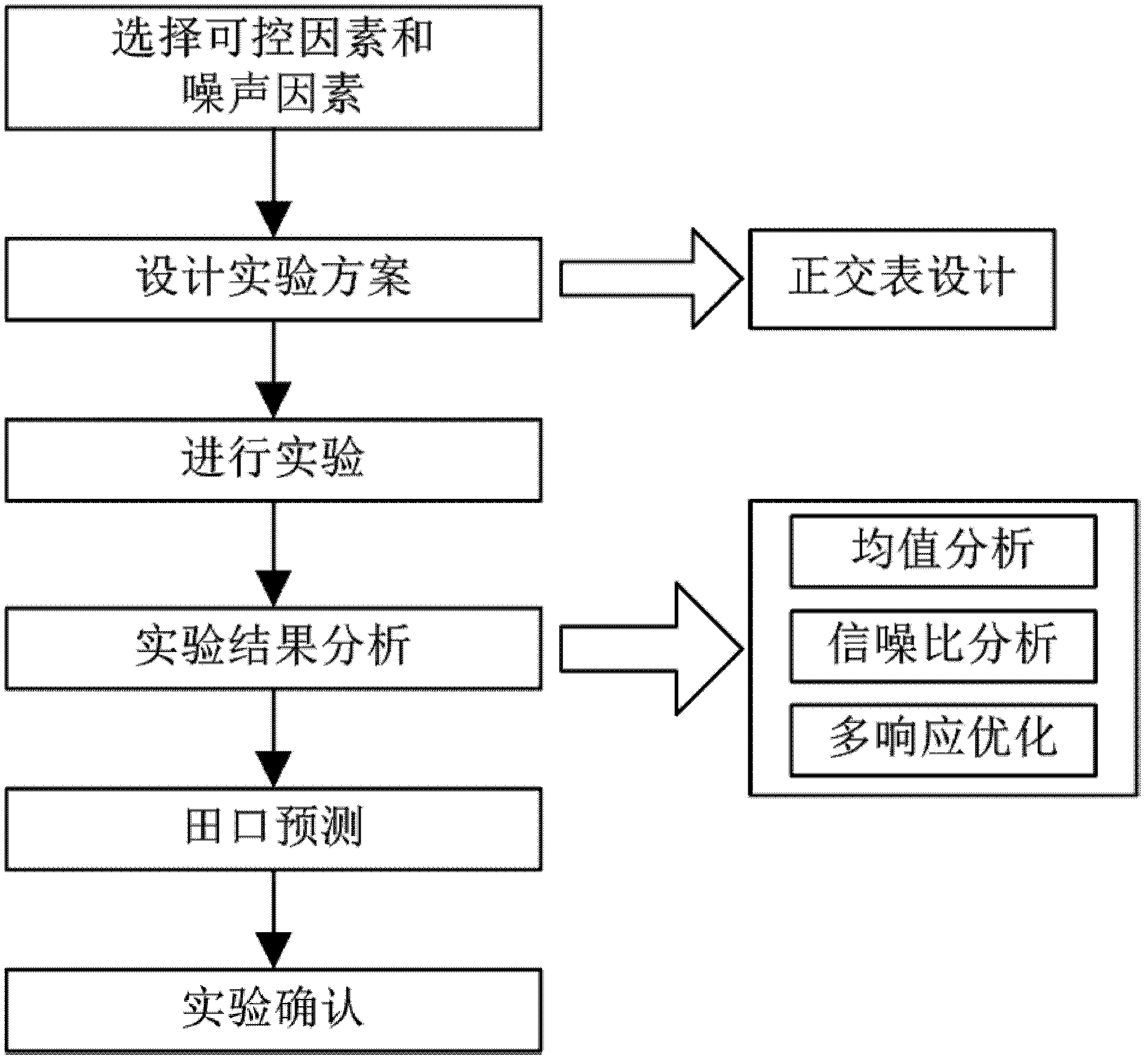

Optimum design method of heat sink based on Taguchi method

InactiveCN102646146AResolve uncertaintyShorten the design cycleSpecial data processing applicationsAviationEngineering

An optimum design method of a heat sink based on the Taguchi method comprises selecting controllable factors and a noise factor; designing an experimental program; performing experiment; analyzing an experimental result; executing the Taguchi method on the experimental result; and finally determining the optimum design by the experiment. The invention adopts simulation combined with Taguchi parameter design, carries out experimental design on relevant parameters of the heat sink, then simulates the heat dissipation effect (power device housing temperature) and heat sink quality by means of simulation method, and analyzes the simulation result, to thereby optimize heat sink parameters and research optimum combination of heat sink parameters. The method has practical value in the technical field of avionic product reliability engineering.

Owner:BEIHANG UNIV

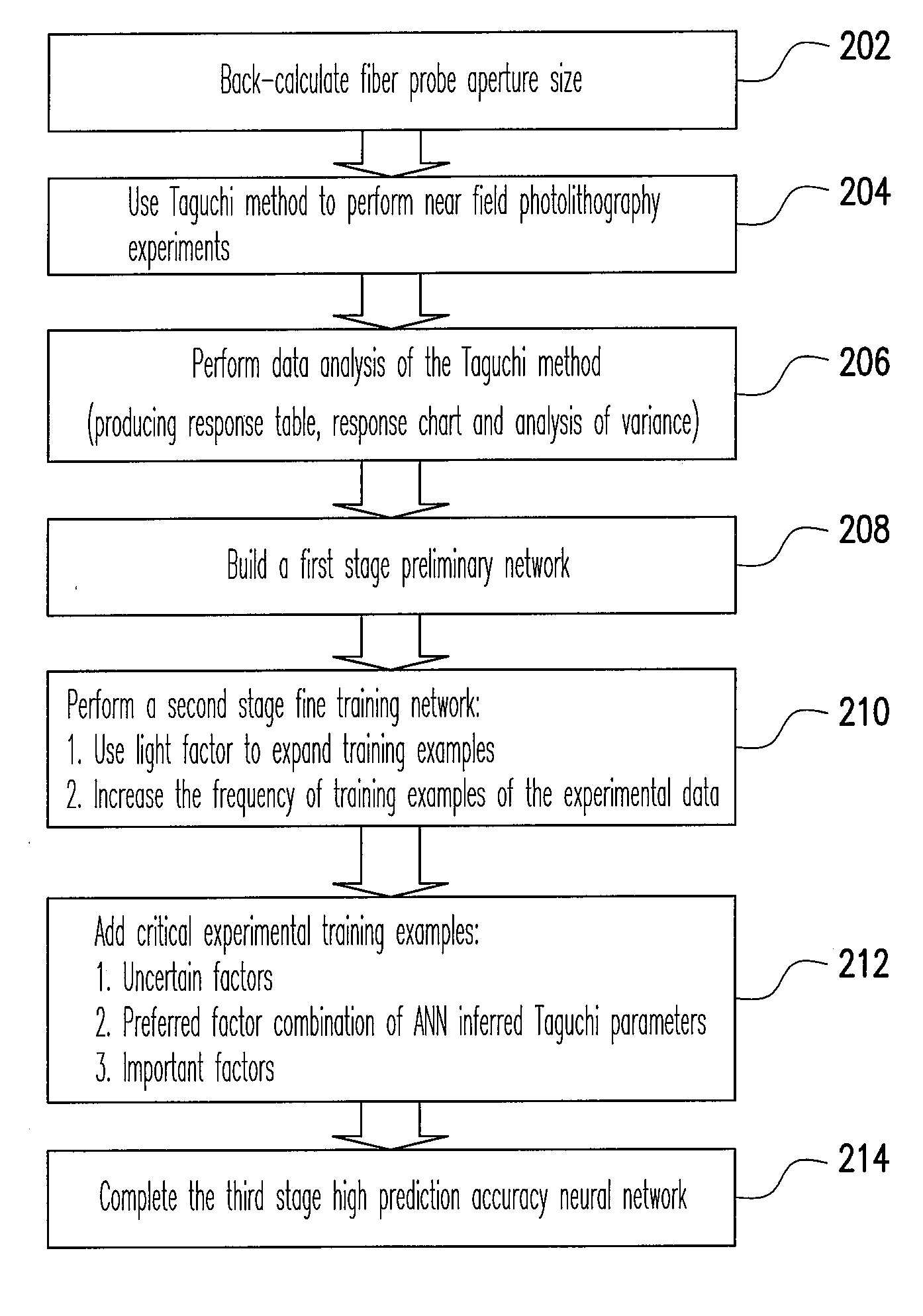

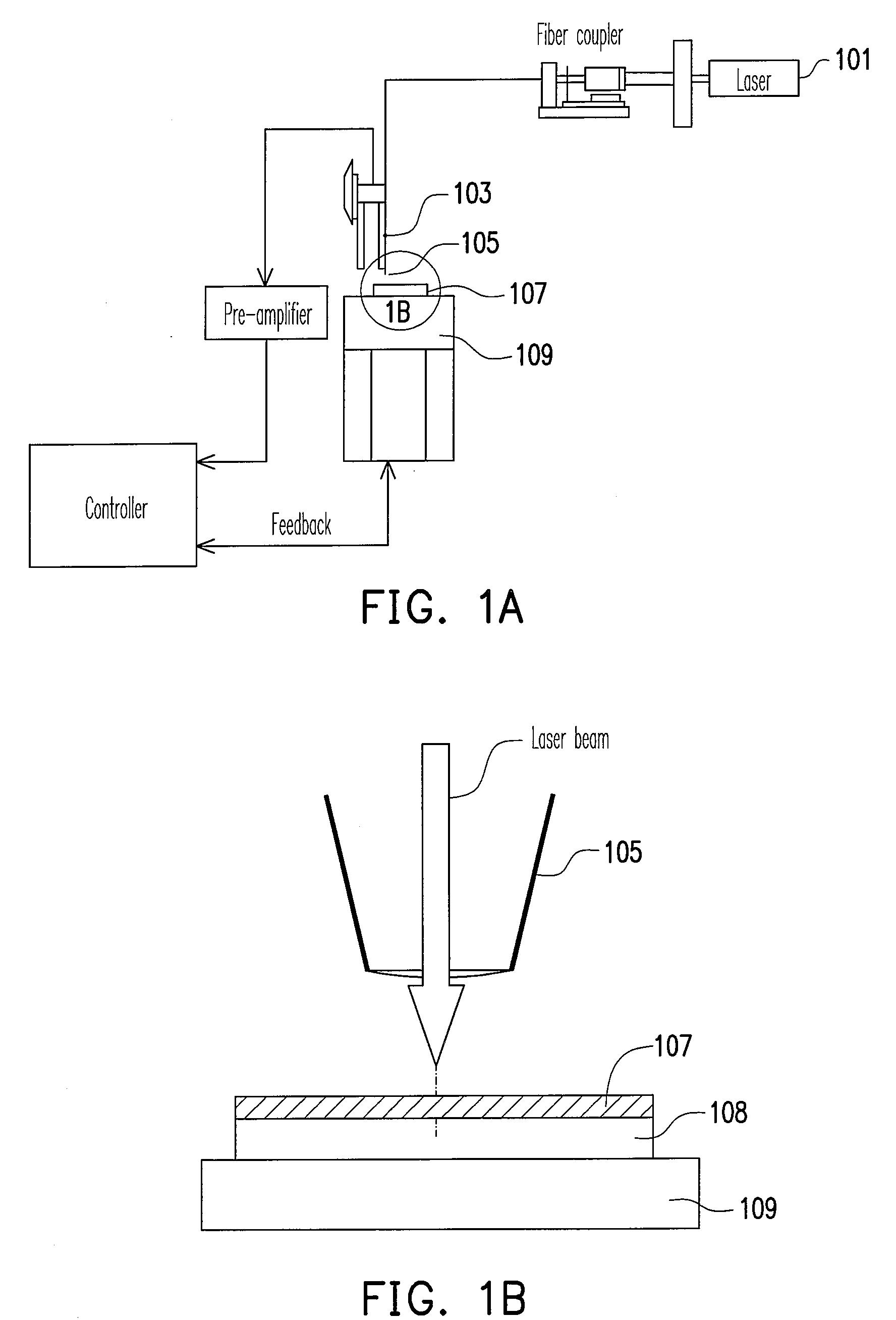

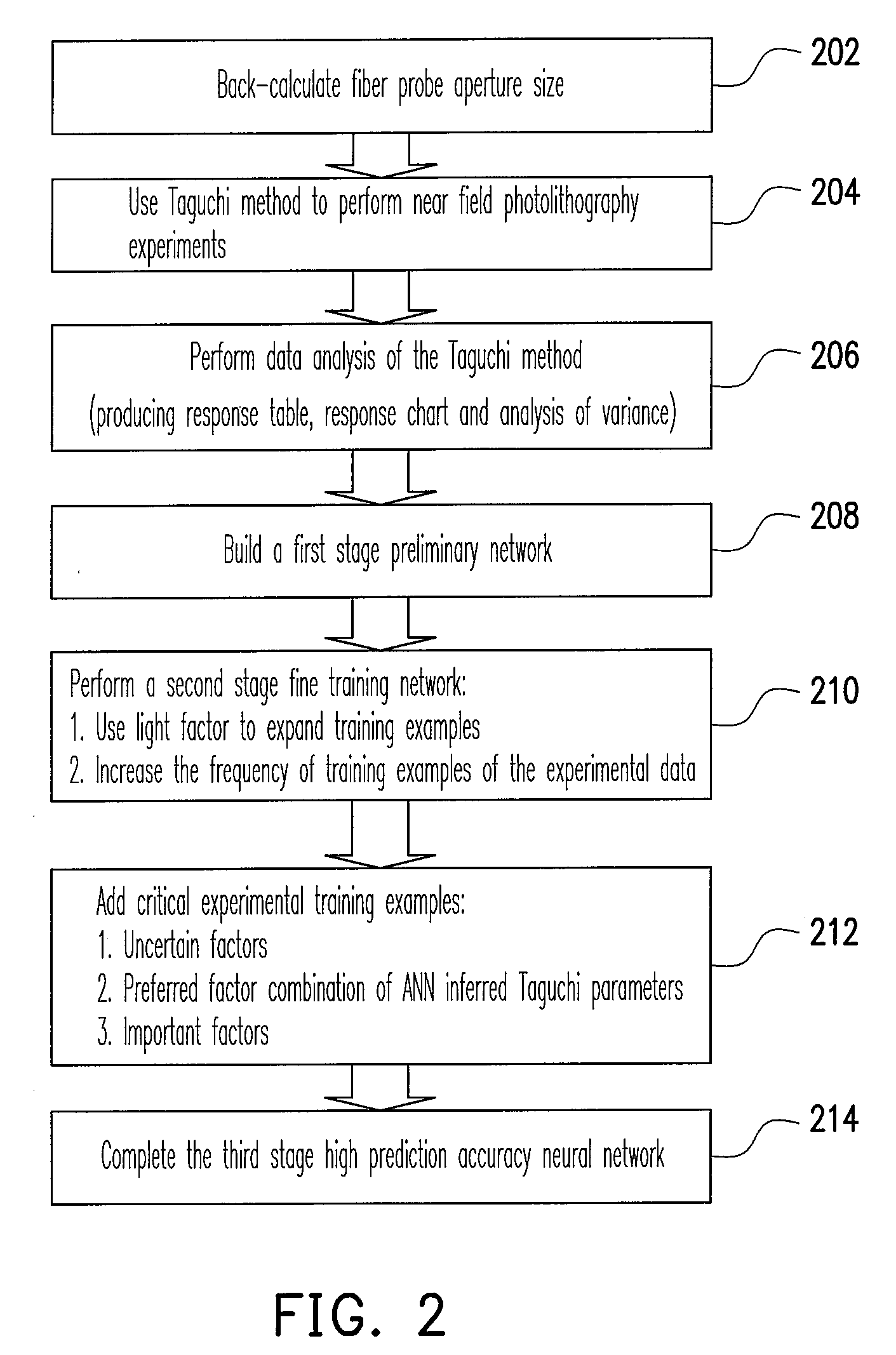

Prediction method of near field photolithography line fabrication using by the combination of taguchi method and neural network

InactiveUS20080222067A1Short forecast timeImprove forecast accuracyGenetic modelsDigital computer detailsNerve networkPredictive methods

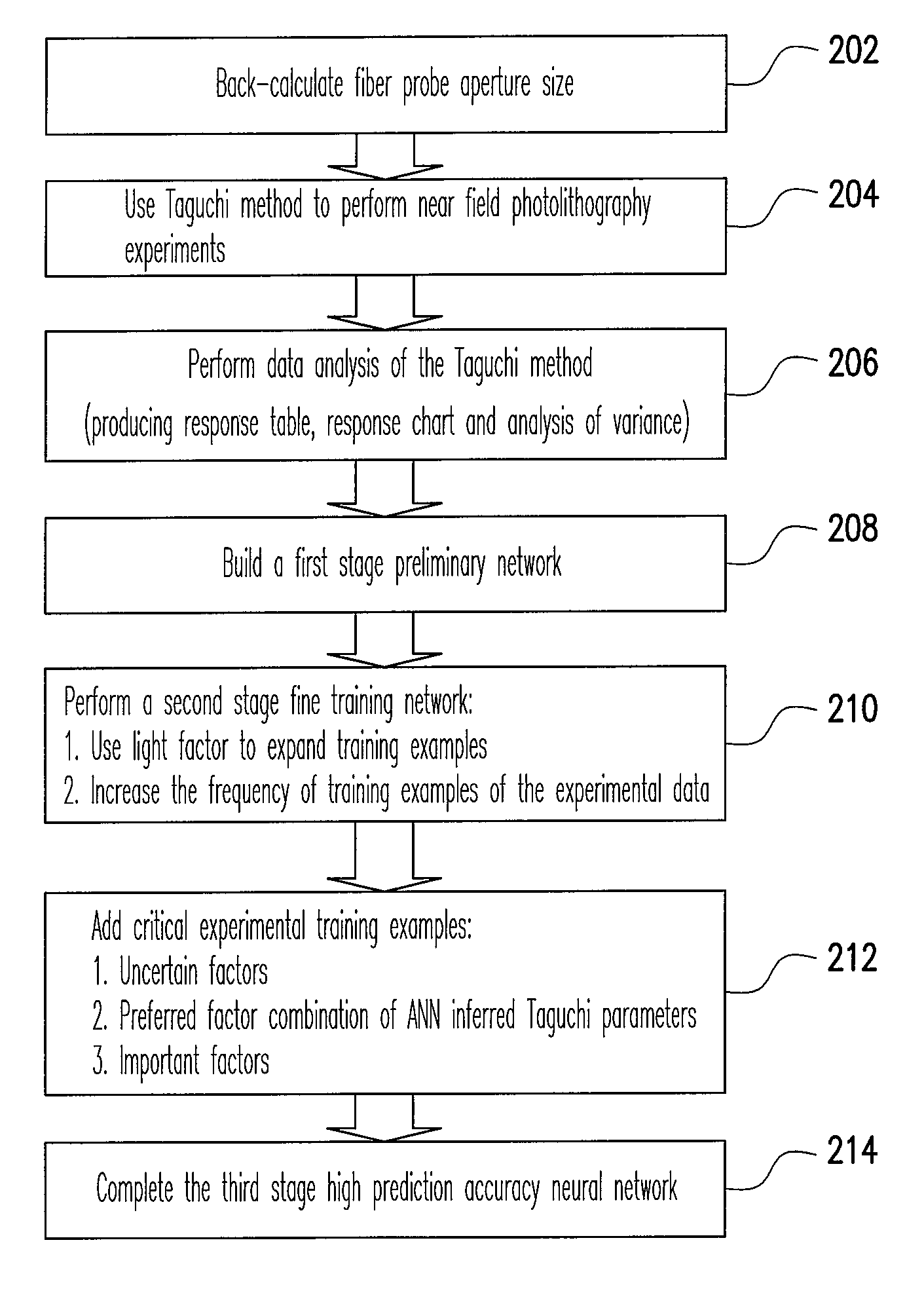

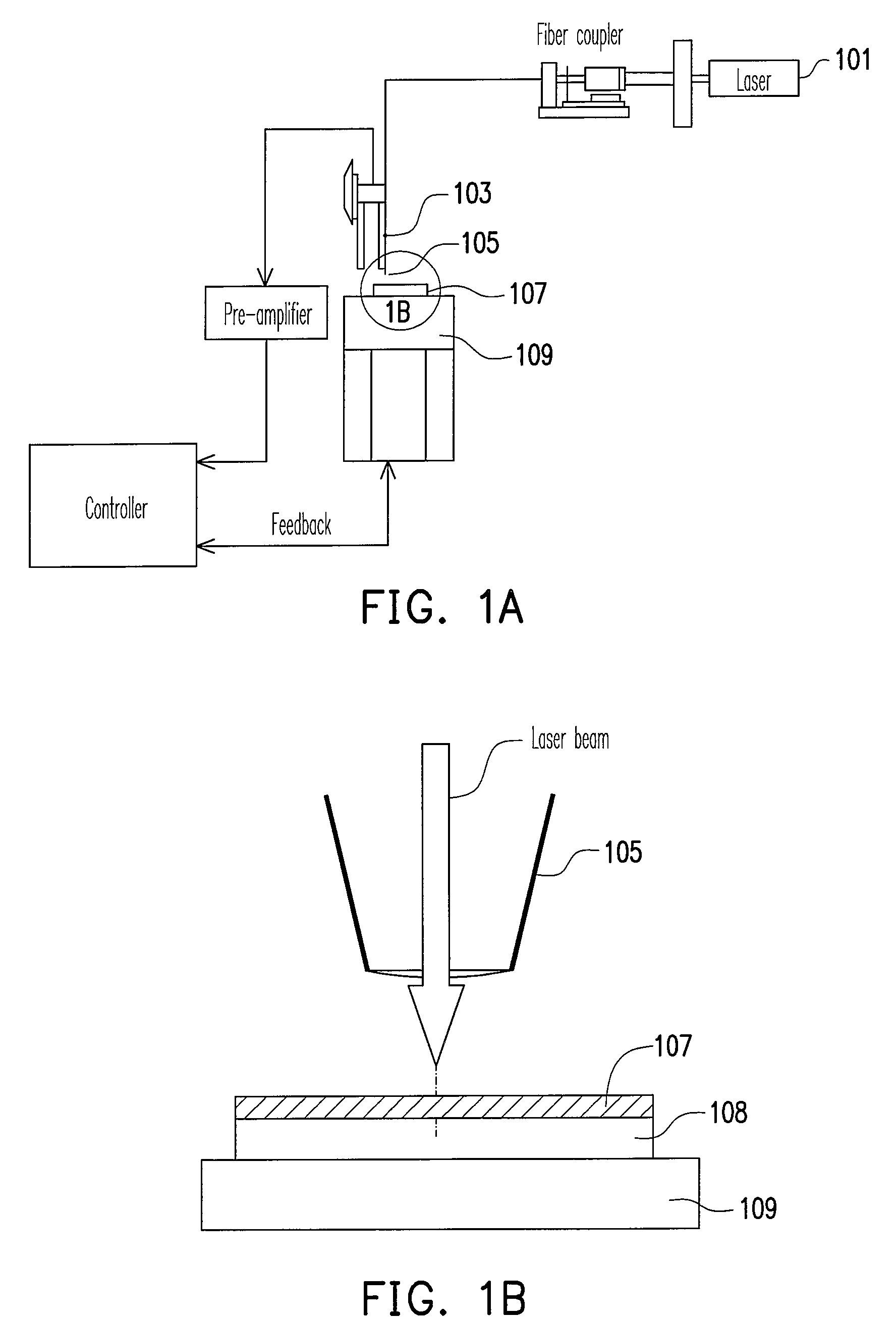

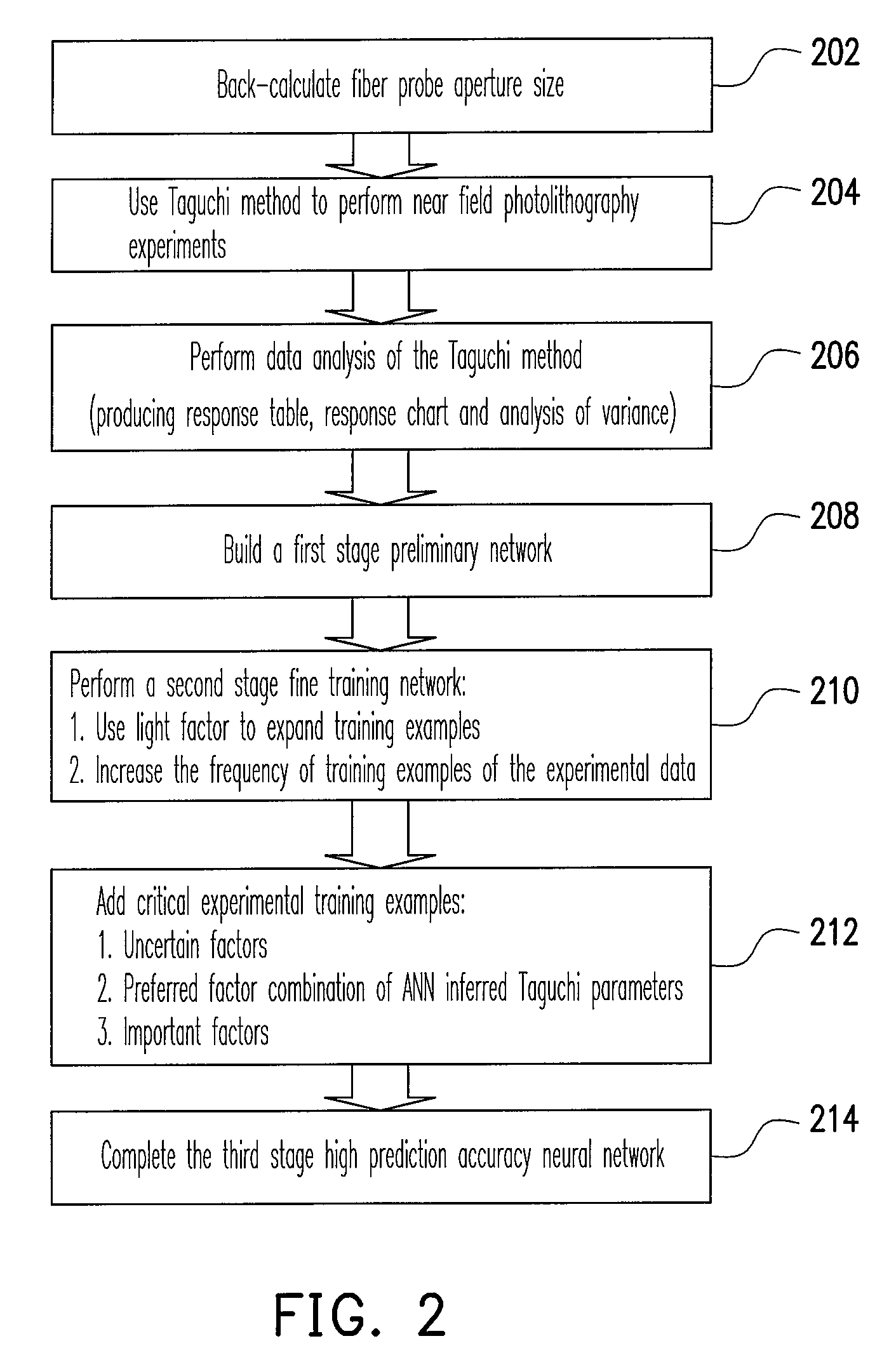

A method of building a set of experimental prediction model that requires fewer experimental frequency, shorter prediction time and higher prediction accuracy by using the advantages of combining the experimental data of Taguchi method and neural network learning is disclosed. The error between the experimentally measured result of photolithography and the simulated result of the theoretical model of near field photolithography is set as an objective function of an inverse method for back calculating fiber probe aperture size, which is adopted in the following Taguchi experiment. The analytical result of Taguchi neural network model of the present invention proves that the Taguchi neural network model can provide more accurate prediction result than the conventional Taguchi network model, and at the same time, improve the demerit of requiring massive training examples of the conventional neural network.

Owner:NAT TAIWAN UNIV OF SCI & TECH

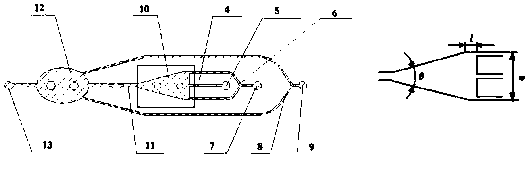

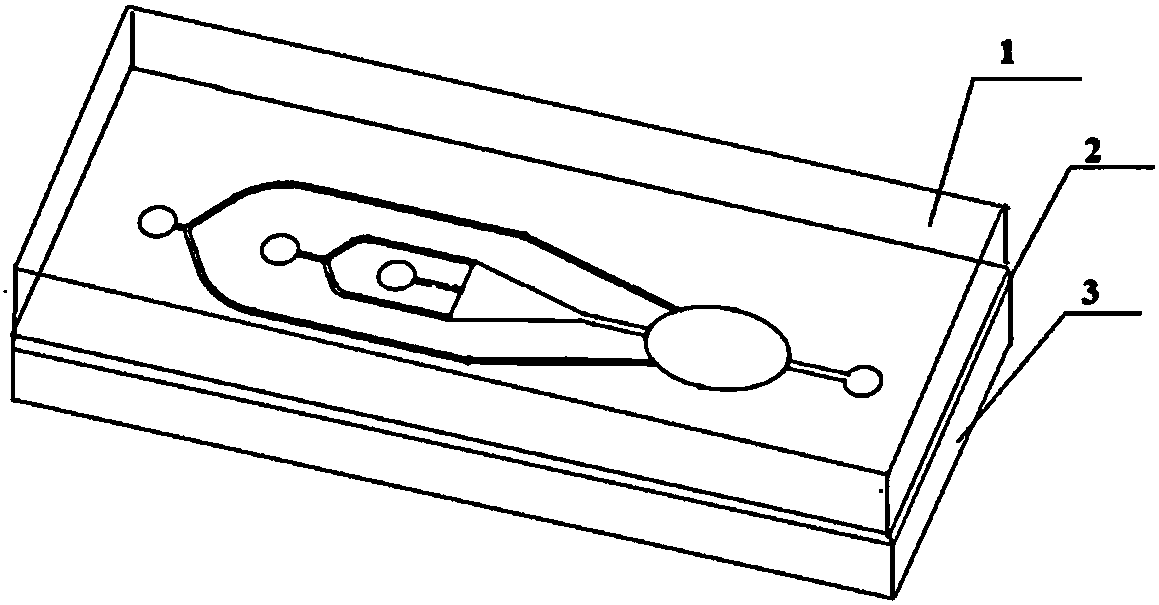

Micro-fluidic chip capable of realizing flow rate relying avoidance of liquid drip dimension

The invention discloses a micro-fluidic chip capable of realizing flow rate relying avoidance of liquid drip dimension, and belongs to the technical field of a micro-fluidic chip. The micro-fluidic chip emphasizes the influence of the interface tension and the geometric configuration on the liquid drip generation; the relying of the liquid drip dimension on the speed can be reduced. The micro-fluidic chip comprises an upper layer passage structure, a middle layer and a lower layer passage structure, wherein the upper layer passage is formed by connecting a dispersed phase passage, a continuousphase passage, a liquid drip generating cavity and a liquid drip observation cavity; meanwhile, a Taguchi method is used for reducing the test times; the optimum geometric parameter structure of theliquid drip generation capability is determined. By using the chip, the liquid drip can be uniformly and stably generated without relying on the two-phase flow rate change; the driving limit of the liquid drip generation is facilitated; the chip performance stability maintenance speed range is expanded, so that the micro liquid drip two-phase flow can be applicable to different driving conditions.

Owner:BEIJING UNIV OF TECH

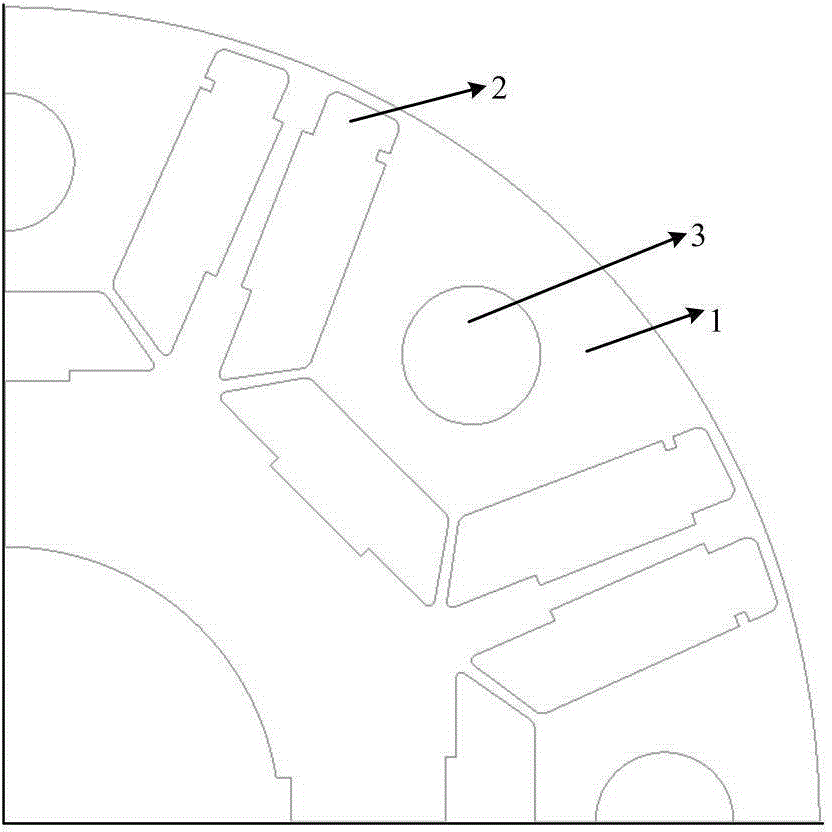

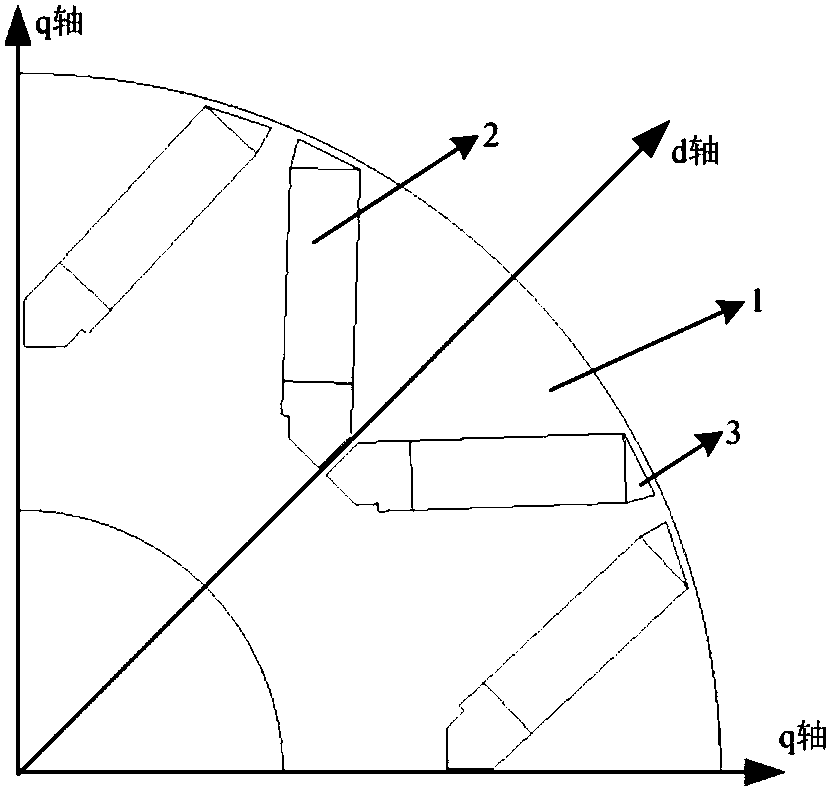

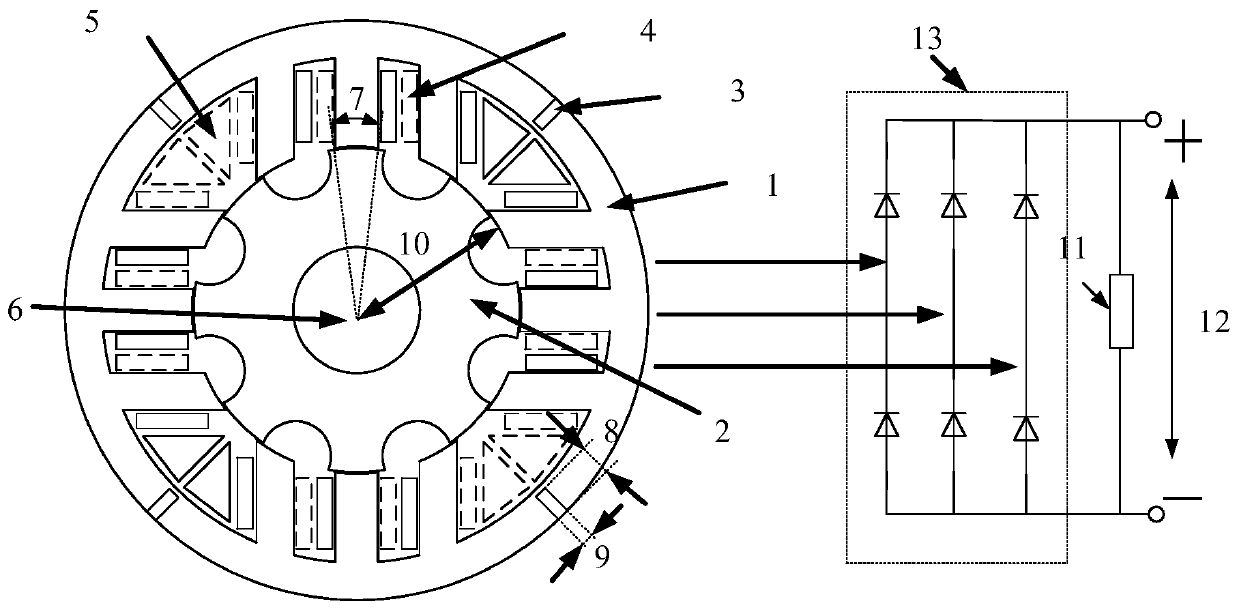

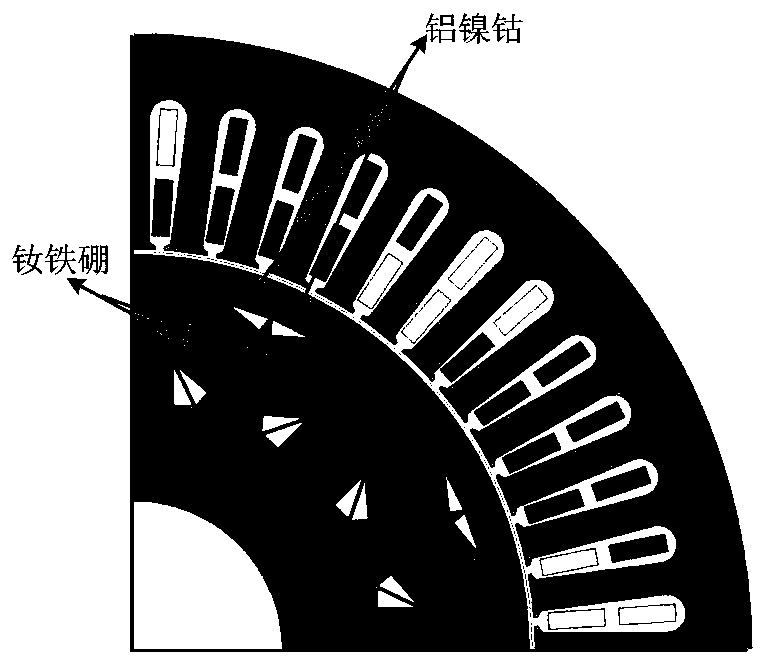

Permanent magnet cavity structure robust design method capable of reducing iron loss of built-in permanent magnet motor

ActiveCN104967262AReduce iron consumptionReduce electromagnetic torqueMagnetic circuit rotating partsManufacturing stator/rotor bodiesHarmonicElectric machinery

The invention relates to a permanent magnet cavity structure robust design method capable of reducing iron loss of a built-in permanent magnet motor. The method comprises steps: initial permanent magnet cavity structures of the motor are determined, and the built-in permanent magnet motor adopts a single layer of U-type permanent magnet structures; the permanent magnet cavity structures of the motor are improved, triangular permanent magnet cavity expansion structures are added at places, near the surface of a rotor iron core, at two sides of each U-type permanent magnet cavity, and the permanent magnet cavities between adjacent poles are connected; and a Taguchi method is used for optimizing the permanent magnet cavity improved structures. The permanent magnet cavity structures of the built-in permanent magnet motor with the single layer of U-type permanent magnet structures are improved, the improved structure can effectively reduce the harmonic component in an air-gap magnetic field, iron loss of the stator and the rotor of the motor is reduced obviously, the optimized permanent magnet cavity structure enables electromagnetic torque ripple and cogging torque of the motor to be reduced obviously, and smooth operation of the motor is enhanced.

Owner:TIANJIN UNIV

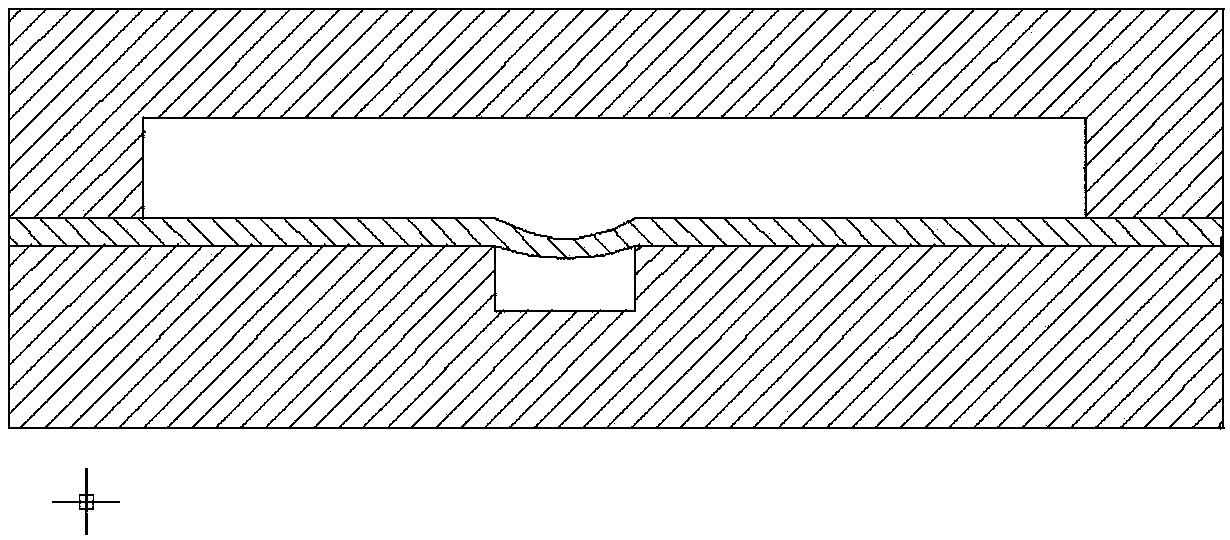

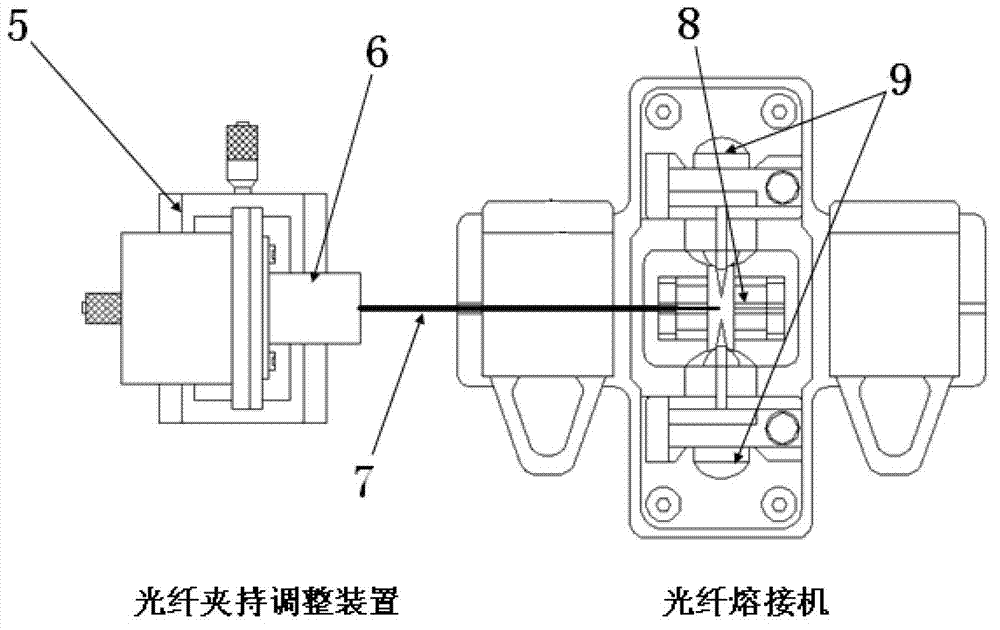

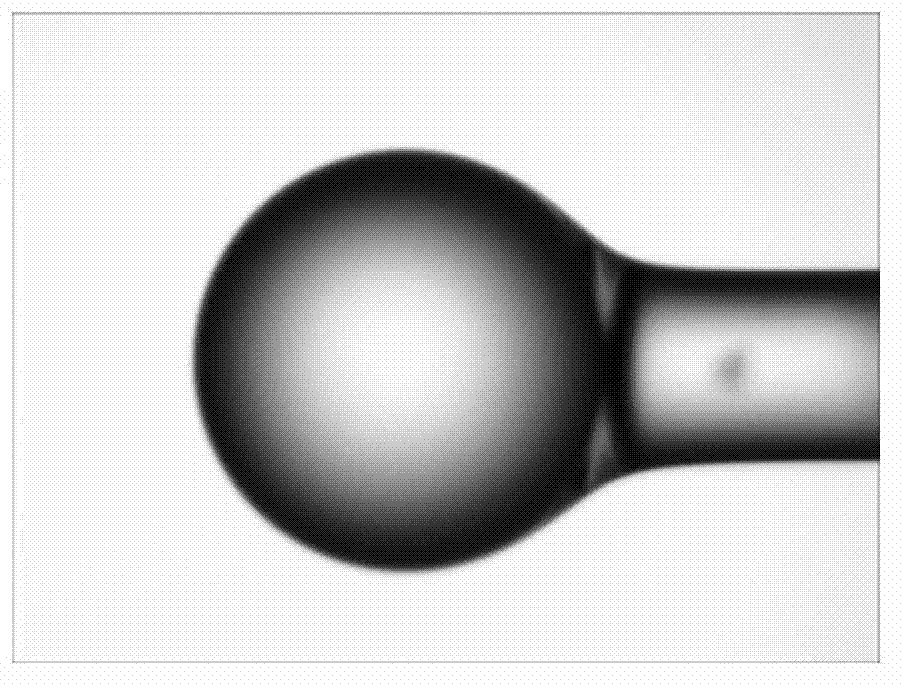

Preparation method of contact-type optical fiber micro probe based on optical fiber tapering technology

ActiveCN103197380ASmall diameterRealize true 3D shape measurementUsing optical meansCoupling light guidesMicrometerEngineering

The invention discloses a preparation method of a contact-type optical fiber micro probe based on an optical fiber tapering technology. Through the optical fiber tapering technology, the diameter of a single mode fiber is attenuated to be in a range of less than 40 micrometers. Then, the single mode fiber after being attenuated is accurately put into a V-type groove in an optical fiber welding machine, and at the same time, the tapered portion of the optical fiber is placed on a discharging region of the optical fiber welding machine. The tapered portion of the optical fiber is heated and fired through the optical fiber welding machine, and the optical fiber is evenly rotated until the end of a tapering optical fiber is melted to be a high-quality micro probe ball. In the process of firing of the optical fiber, process control parameters of the optical fiber welding machine are reasonably arranged based on a taguchi method, the optical fiber is rotated to overcome the impact caused by gravity, and accordingly the micro probe ball which is small in ball diameter, good in sphericity and small in eccentricity is obtained on the end portion of the tapering optical fiber. The micro probe ball and the tapering optical fiber form the contact-type optical fiber probe.

Owner:HEFEI UNIV OF TECH

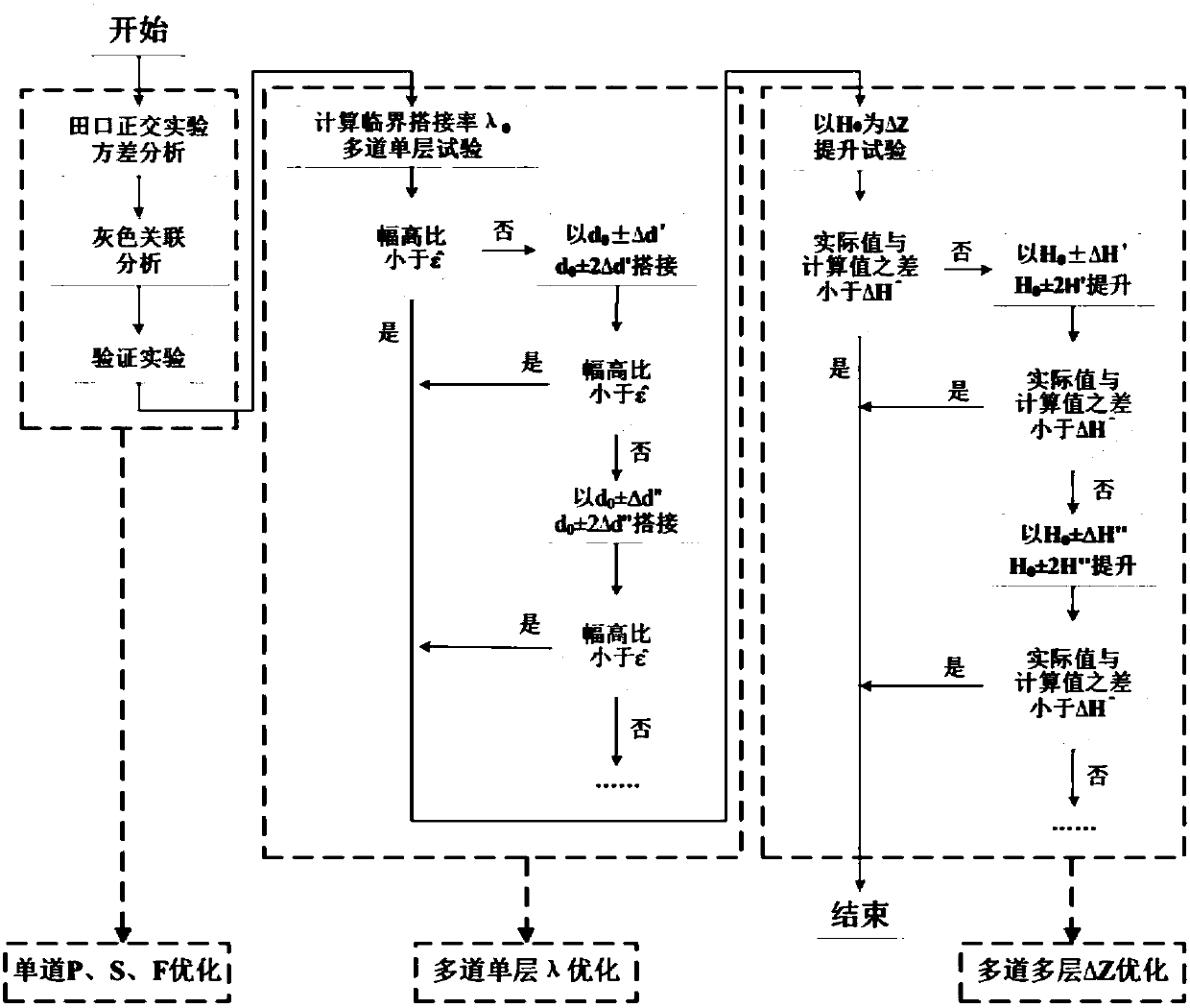

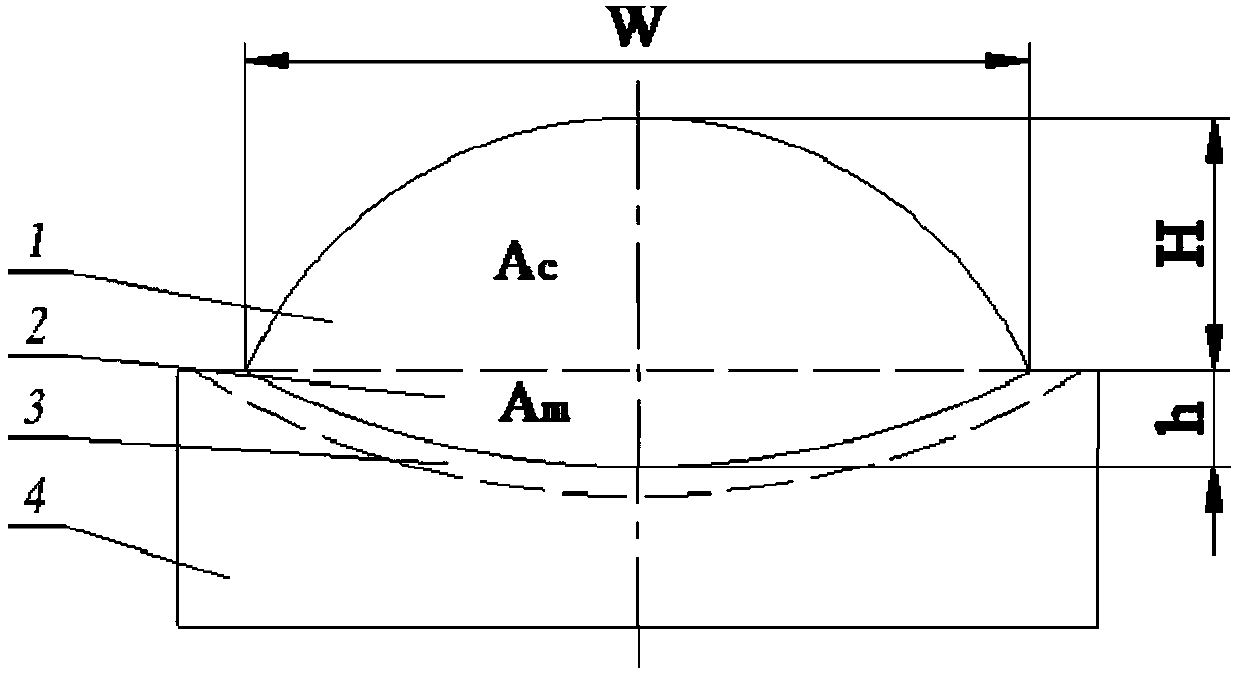

Method for optimizing parameters of laser cladding process on plane

ActiveCN108559995AImprove accuracy and reliabilityAnalyze Impact TrendsMetallic material coating processesGrey correlation analysisAnalysis of variance

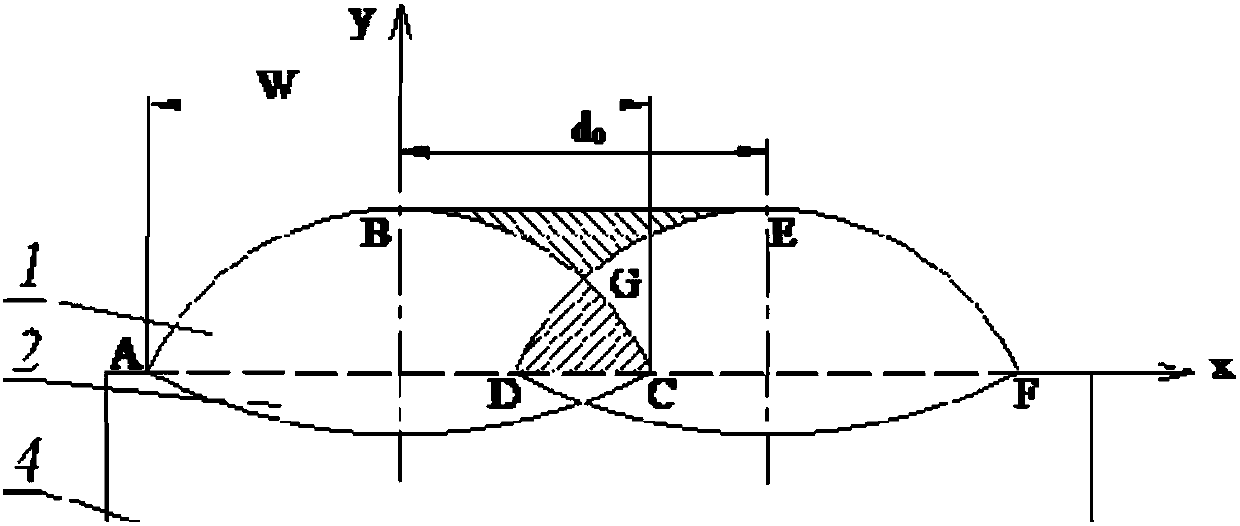

The invention relates to a method for optimizing the parameters of a laser cladding process on a plane. The method for optimizing the parameters of the laser cladding process on the plane comprises the following steps: S1, taking a laser power, a scanning speed and a powder feeding speed as the parameters to be optimized, designing an orthogonal experiment according to a Taguchi method, and takinga weld width, a weld height and a dilution rate as response targets and carrying out variance analysis; S2, analyzing the three response targets by virtue of a grey correlation analysis method and then obtaining the final optimal parameter combination; S3, fitting the outline of a cladding layer under the final optimal parameter combination into a function and establishing a geometric model, calculating and analyzing, and then obtaining the optimal value of an overlapping rate; and S4, carrying out multi-channel and multi-layer cladding experiment, calculating and analyzing, and then obtaining the optimal value of a Z-axis lifting amount. The method for optimizing the parameters of the laser cladding process on the plane is capable of conveniently, rapidly, accurately and reliably obtaining the optimal parameters in a single-channel cladding process, a single-channel and multi-layer cladding process and a multi-channel and multi-layer cladding process when different cladding powders and / or laser cladding devices are used for carrying out laser cladding experiment on the plane.

Owner:NORTHEASTERN UNIV

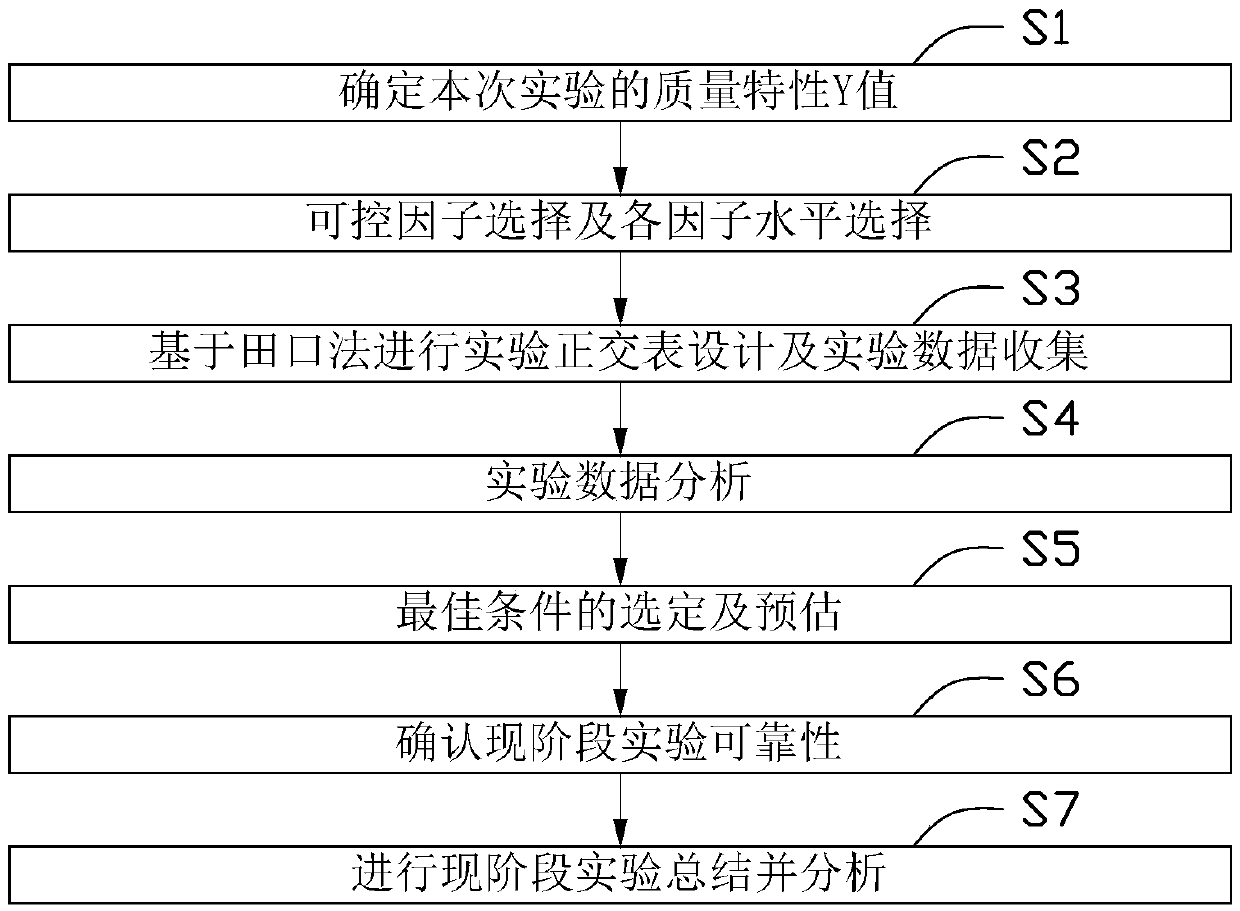

Optimization method for metal 3D printing technology parameters

InactiveCN110560685AReduce optimization costsReduce the number of experimentsAdditive manufacturing apparatusIncreasing energy efficiencyExperimental data analysisLayer thickness

The invention provides an optimization method for metal 3D printing technology parameters. The method comprises the steps of determining a quality characteristic Y value of this experiment; selectingcontrollable factors and all factor levels; designing an experiment orthogonal table and collecting experiment data based on a Taguchi method; analyzing the experiment data; selecting and estimating an optimal condition; determining the experiment reliability of the present stage; carrying out an experiment summary of the present stage and carrying out analysis. According to the optimization method for the metal 3D printing technology parameters, based on the Taguchi method, the experiment frequency is reduced, and the cost of optimizing the technology parameters is lowered. The rule of the influence of the controllable technology parameters such as powder spreading layer thickness, laser power, scanning speed and scanning line spacing distance on the specific density of a metal 3D printing part is disclosed.

Owner:FUSHIRUI PRECISION IND ZHENGZHOU CO LTD

Prediction method of near field photolithography line fabrication using by the combination of taguchi method and neural network

InactiveUS7747419B2Avoid excessive frequencyShort forecast timeGenetic modelsDigital computer detailsNerve networkPredictive methods

Owner:NAT TAIWAN UNIV OF SCI & TECH

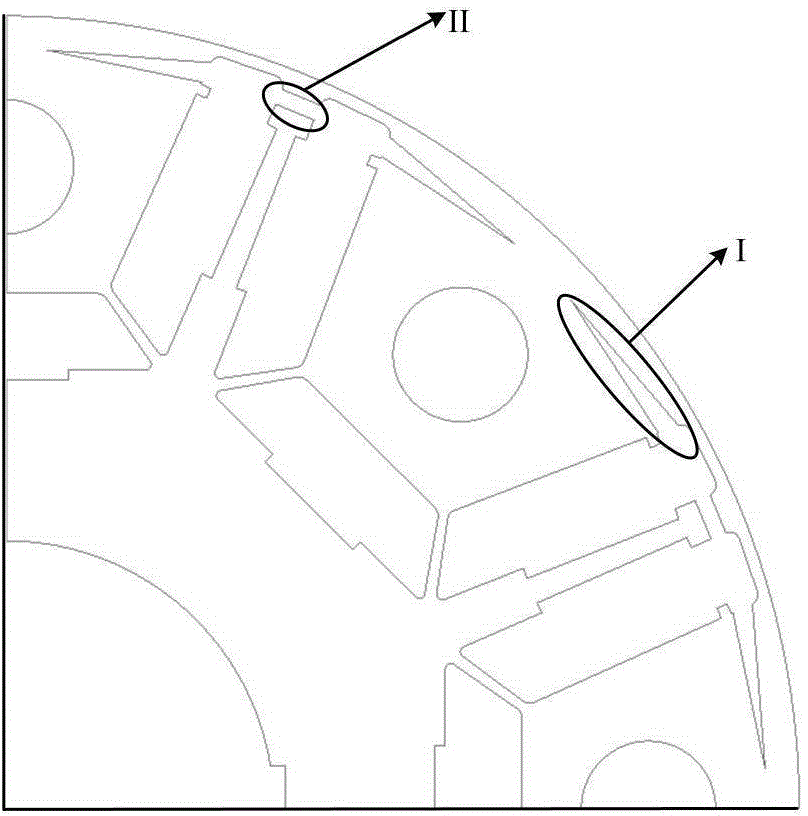

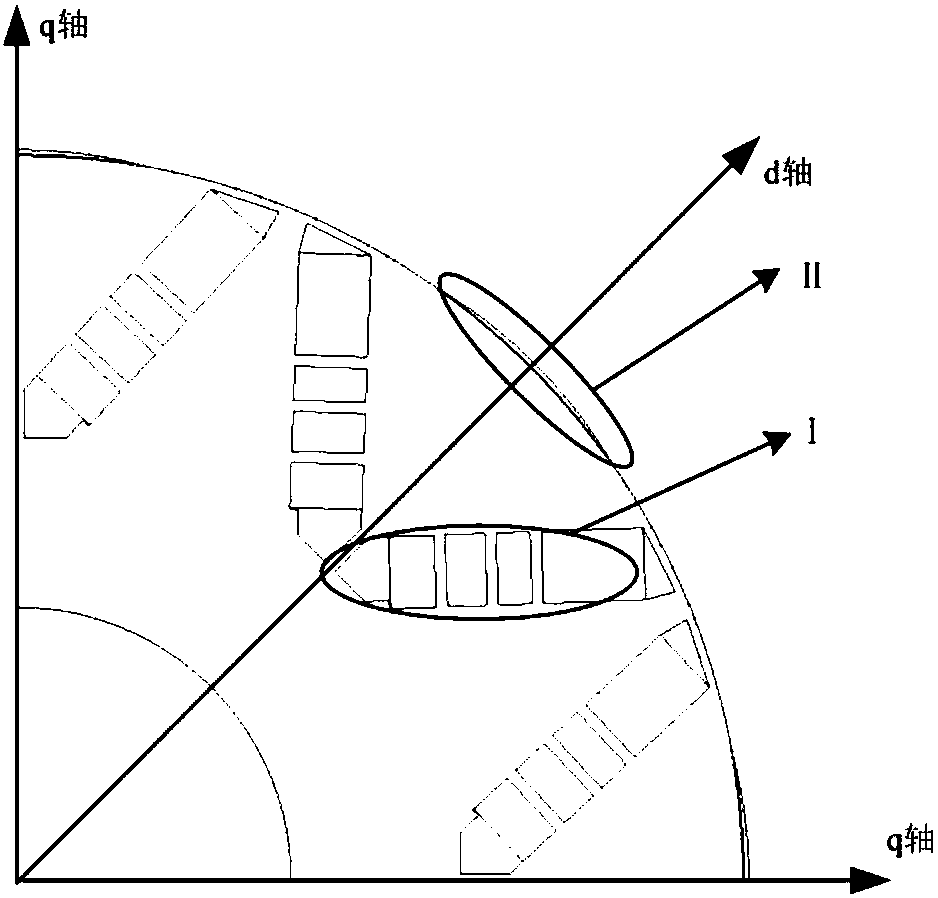

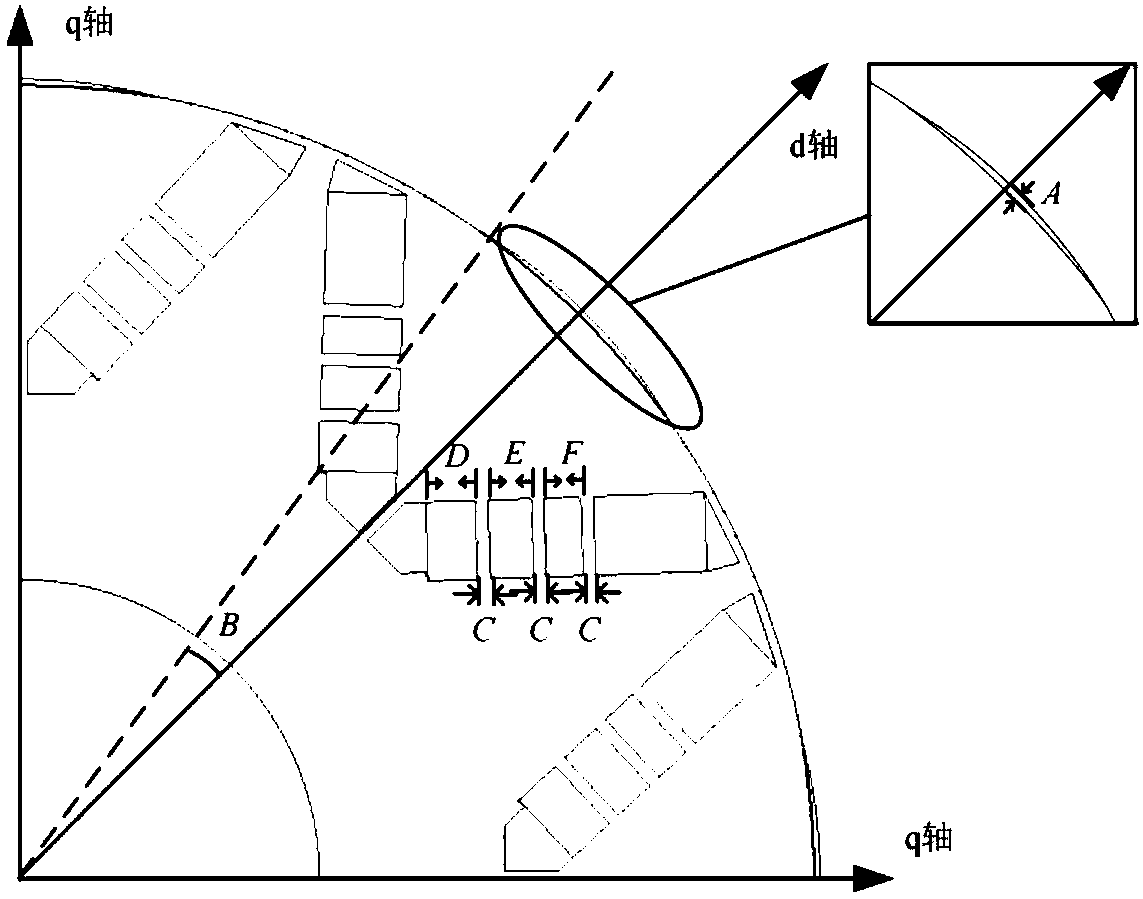

Rotor structural robustness design method for widening built-in permanent magnet synchronous motor speed range

ActiveCN108566004AExtended speed rangeImprove stabilityMagnetic circuit rotating partsPermanent magnet synchronous motorEngineering

The invention relates to a rotor structural robustness design method for widening a built-in permanent magnet synchronous motor speed range. The method comprises: determining the initial rotor structure of a motor and providing a permanent magnet with a single-layer V-shaped structure; improving the rotor structure of the motor; using a Taguchi method to optimize the above improved structural scheme, and determining an optimization variable, an optimization objective and a constraint condition; establishing a factor level table; performing finite element simulation on the motor under differentconditions, and obtaining the values of d-axis inductance, the q-axis inductance and the electromagnetic torque under different factor levels; performing average value analysis; performing variance analysis on a result based on the average analysis; and determining the optimal solution and improving a prototype.

Owner:TIANJIN UNIV

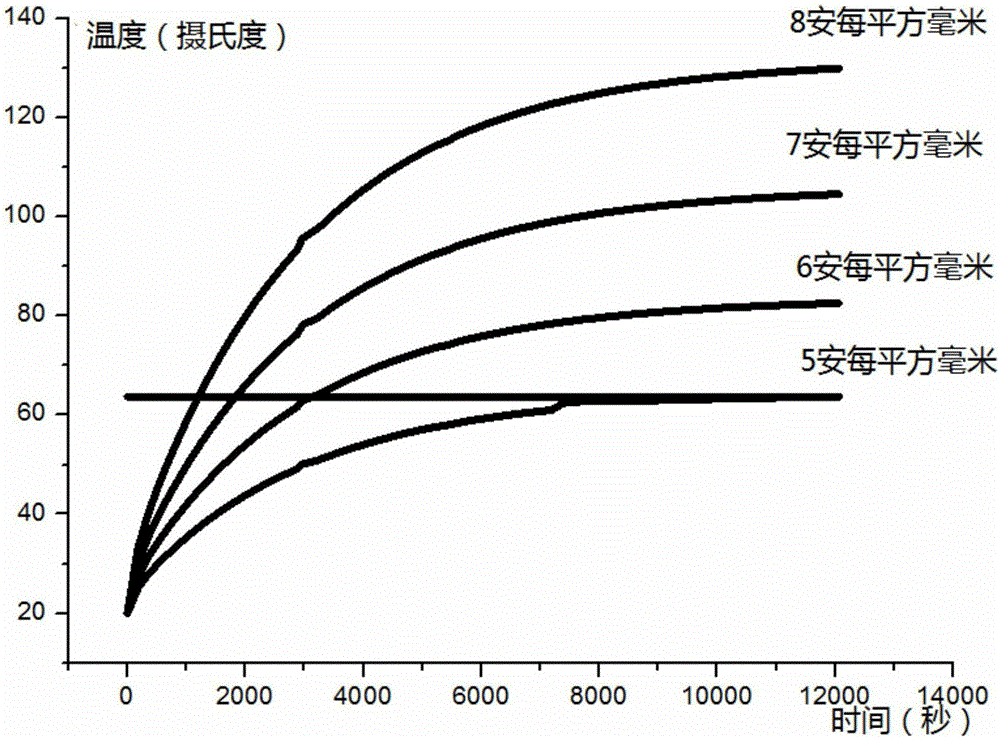

Method for determining working current and time of permanent-magnet linear motor based on taguchi method

ActiveCN105844026AShorten the timeSave resourcesDesign optimisation/simulationSpecial data processing applicationsEngineeringCooling time

The invention discloses a method for determining the working current and time of a permanent-magnet linear motor based on a taguchi method. The method comprises the following steps of: firstly, performing temperature rising and cooling tests of a test motor in the event that environmental conditions are constant; then, calculating steady temperature rising and cooling processes of the test motor under different current densities by using an electromagnetic-thermal coupling finite element calculation method, furthermore, comparing simulation and test results, if the simulation and test results are same, drawing out temperature rising and cooling curves of the motor, and if the simulation and test results are not same, modifying a simulation parameter according to an experimental result until the simulation and test results are same; and finally, determining temperature of the motor under different current densities, different operation times and different cooling times according to the determined temperature rising and cooling curves of the motor, and furthermore, obtaining temperature rising combinations most according with engineering practices of the selected motor under the current densities, the operation times and the cooling times by using a taguchi algorithm, such that an optimal combination is obtained.

Owner:SOUTHEAST UNIV

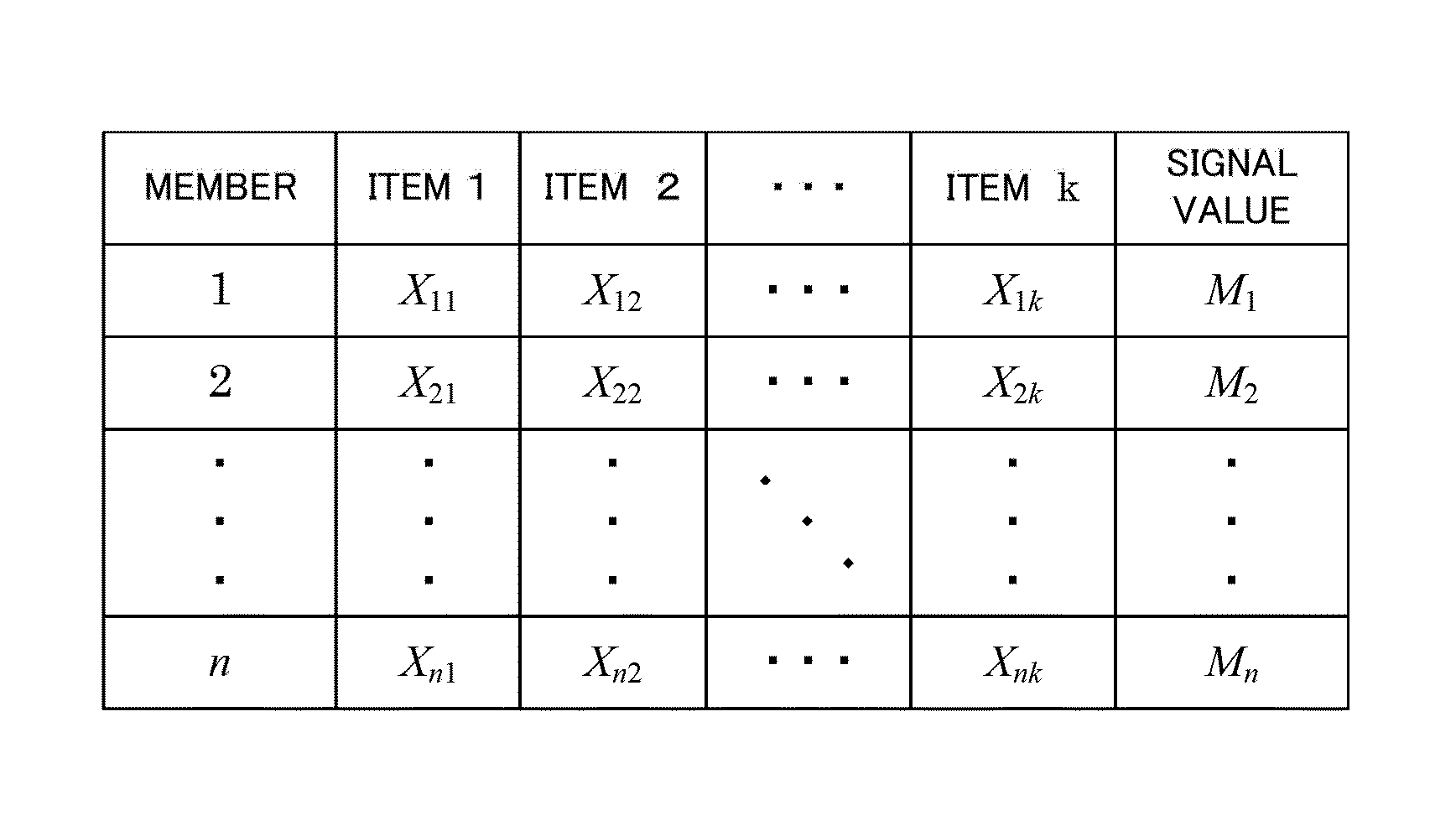

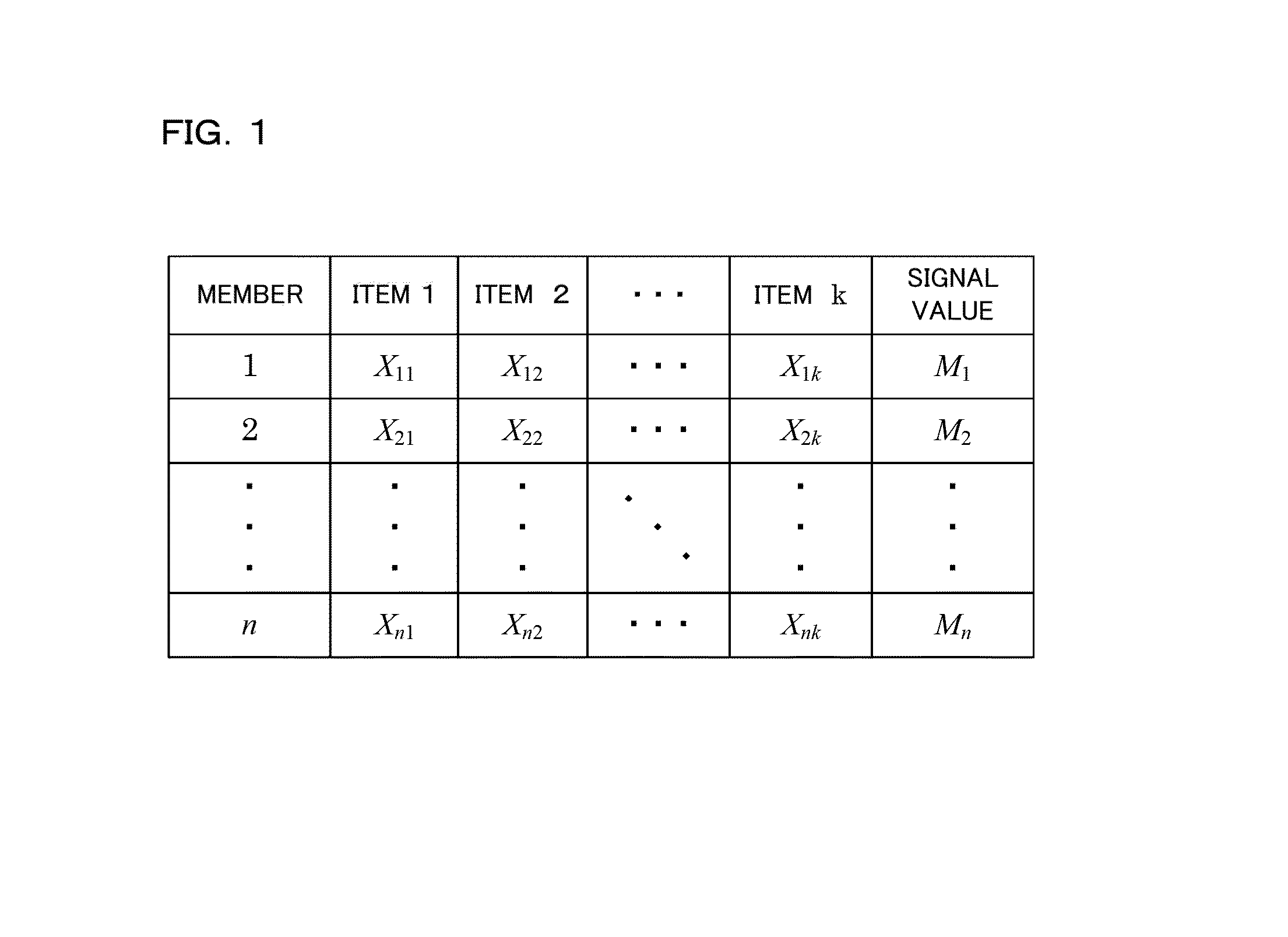

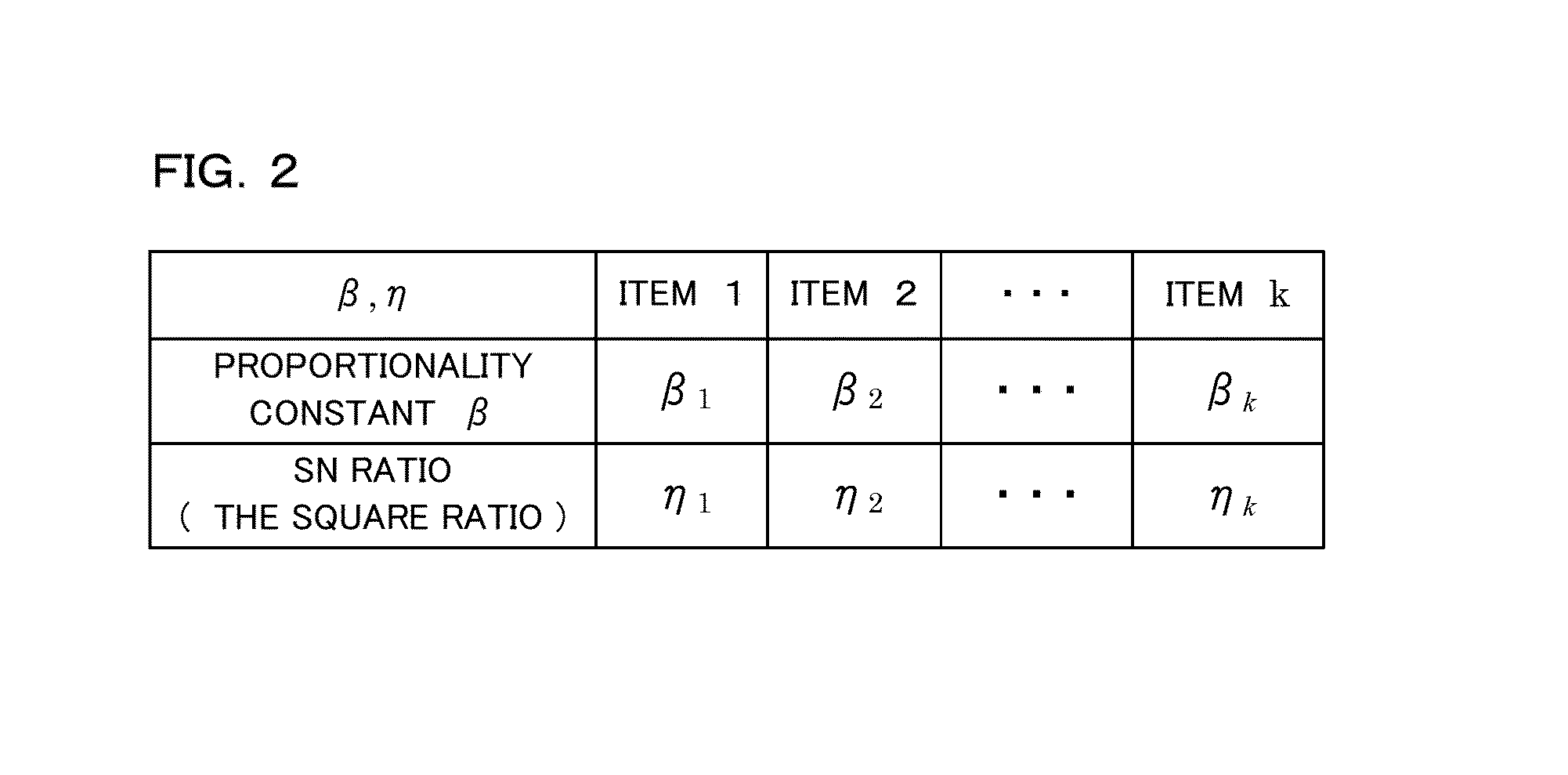

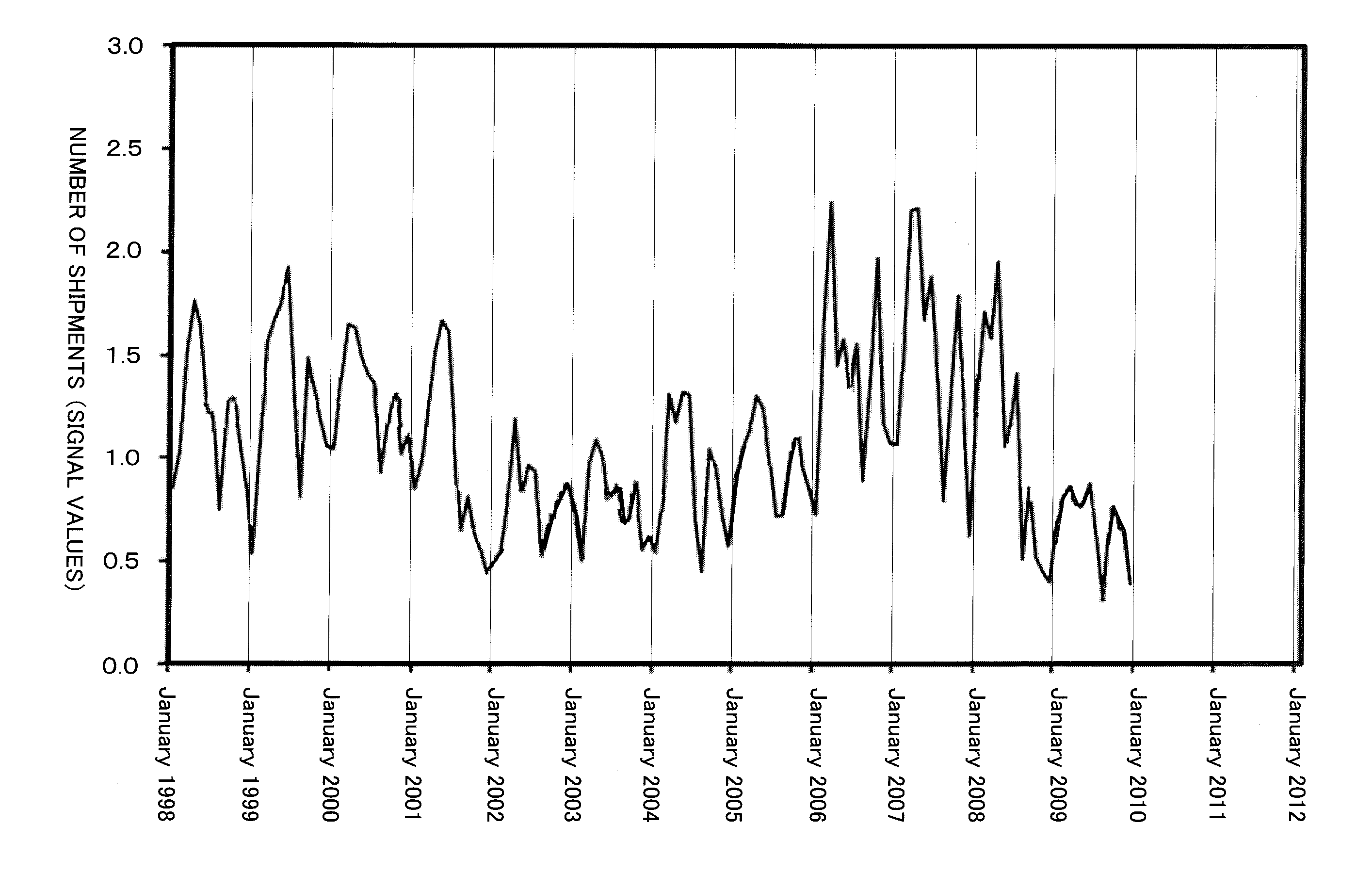

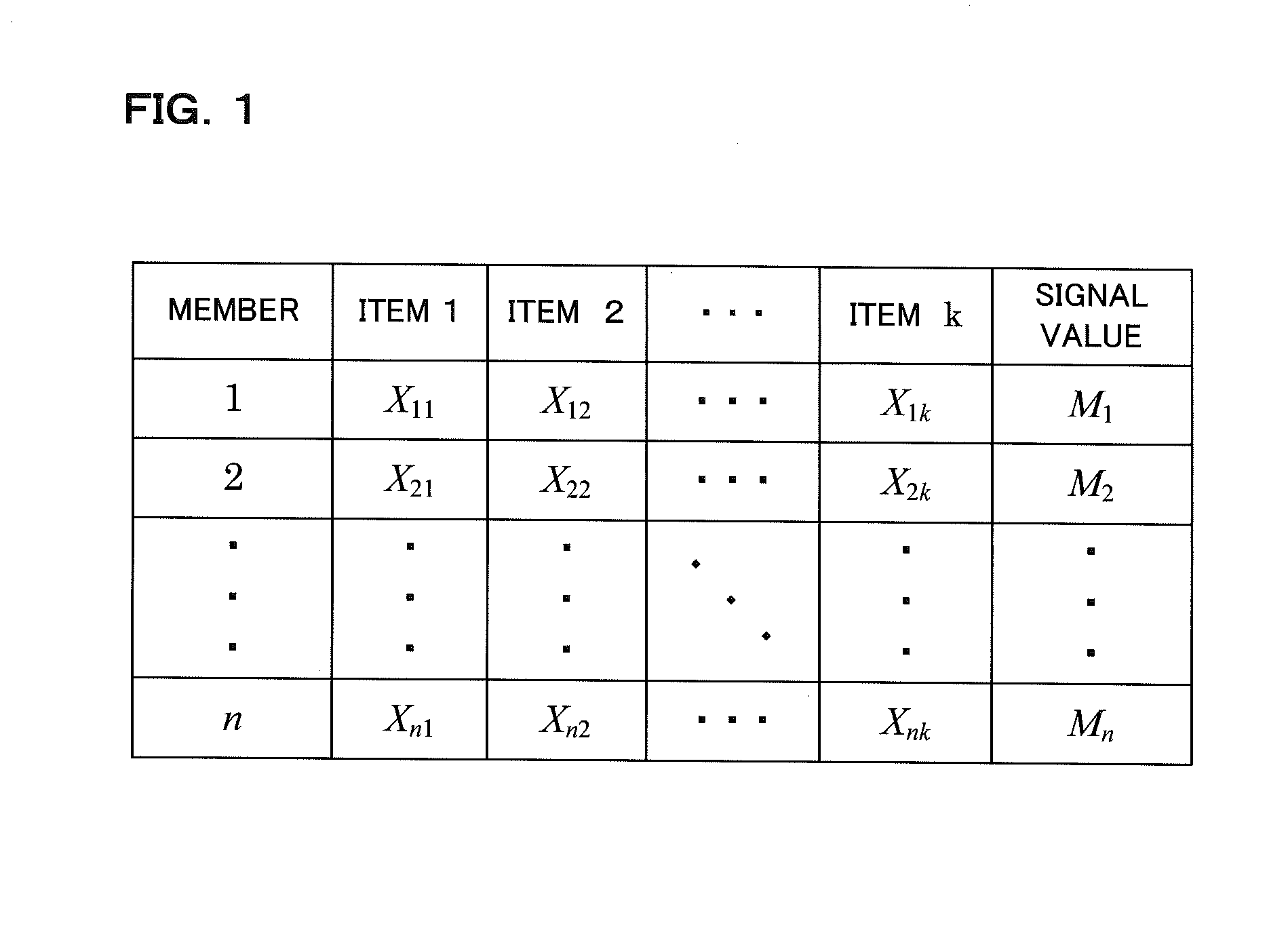

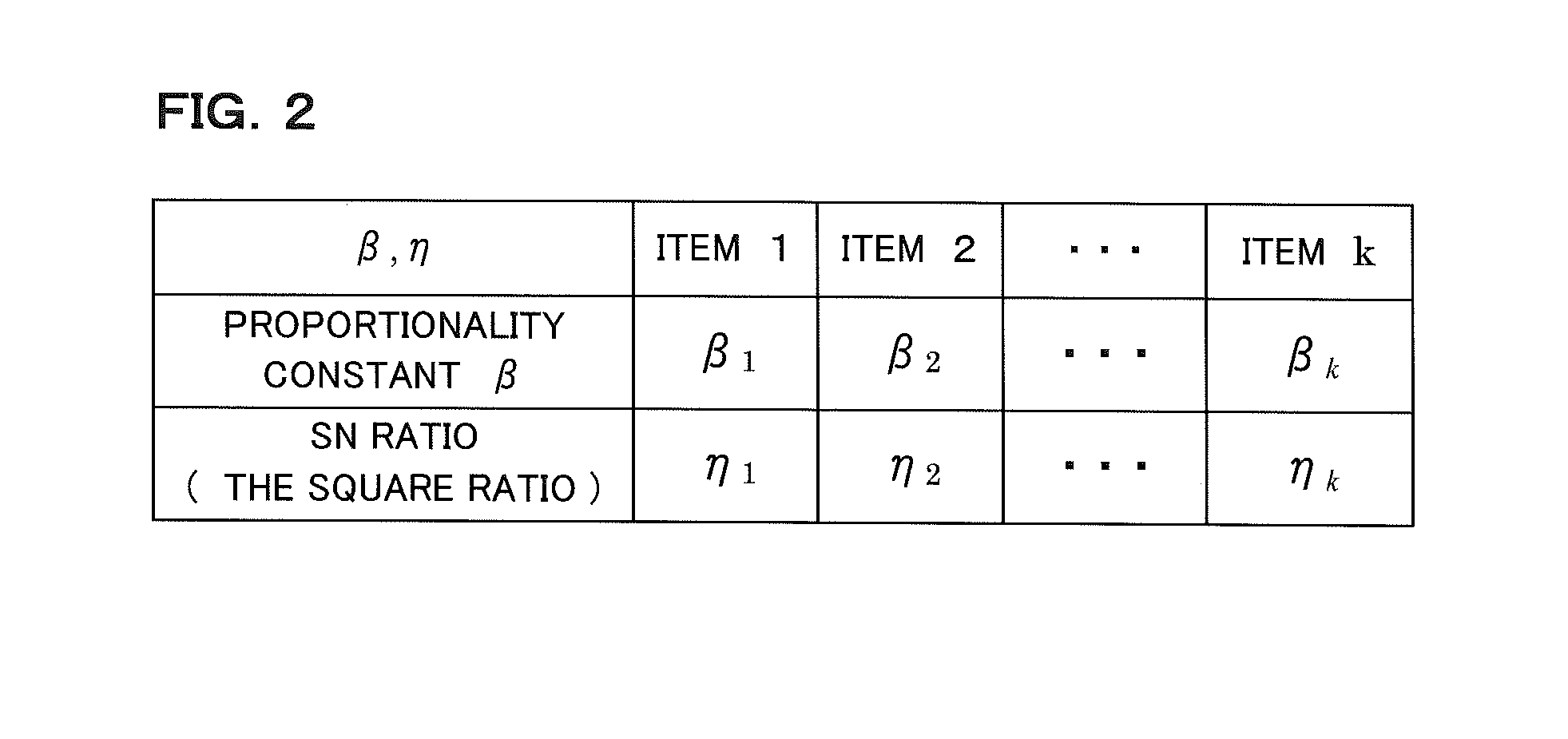

Prediction device, prediction method, and computer readable medium

InactiveUS20150339579A1High precisionEliminate the effects ofForecastingChaos modelsTemporal changeAlgorithm

Provided are a prediction device, a prediction method, and a computer program, which related to prediction method using Taguchi-method, and which reflect, in addition to a time difference model, trends in changes over time, thus further improving prediction accuracy. For example, the prediction device determines, from signal values stored in a time series and data for each item, whether or not the signal trend of the signal values has periodicity, and if the signal trend has not periodicity, then a signal period is selected on the basis of the most recent signal trend and the MD trend for each item, and Taguchi-method is used on the data for each item and the signal values in the selected signal period, and prediction is carried out.

Owner:YANMAR CO LTD

Prediction device, prediction method, and computer readable medium

InactiveUS20150170169A1Contribution to effectHigh precisionForecastingMarketingTemporal changeAlgorithm

Provided are a prediction device, a prediction method, and a computer program, related to prediction method using Taguchi-method, and which reflect, in addition to a time difference model, trends, in changes over time, thus further improving prediction accuracy. For example, the prediction device selects, from signal values stored in a time series and data for each item, a period based on the MD of the data for each item and the trend of the MD, namely a signal period in which the data for each item is similar, and carries out a prediction using Taguchi-method on the signal values and data for each item in the selected period.

Owner:YANMAR CO LTD

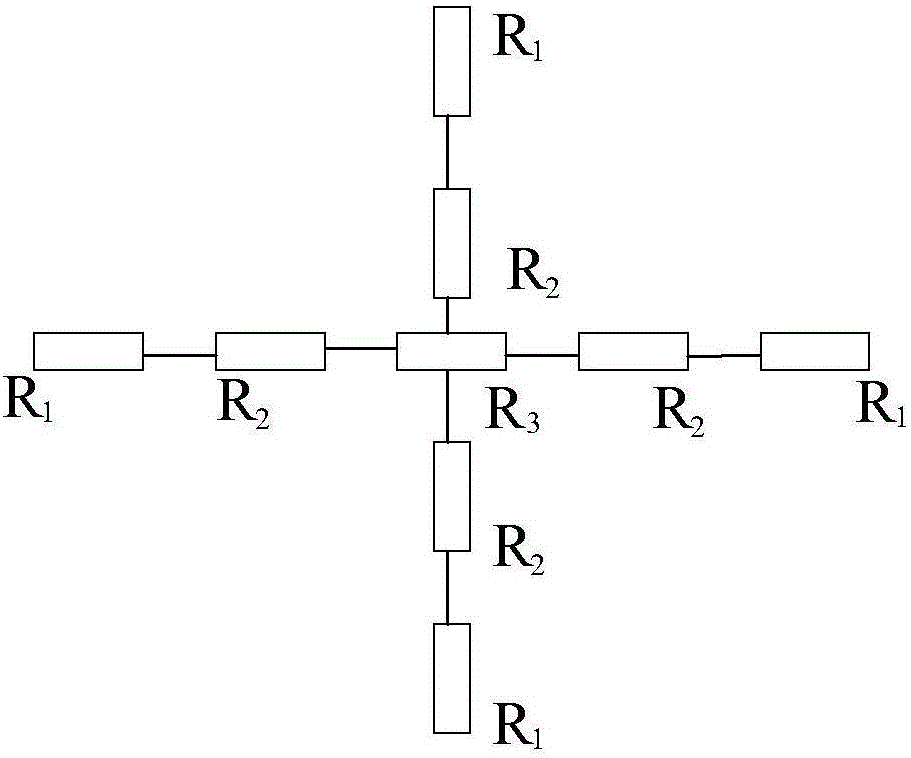

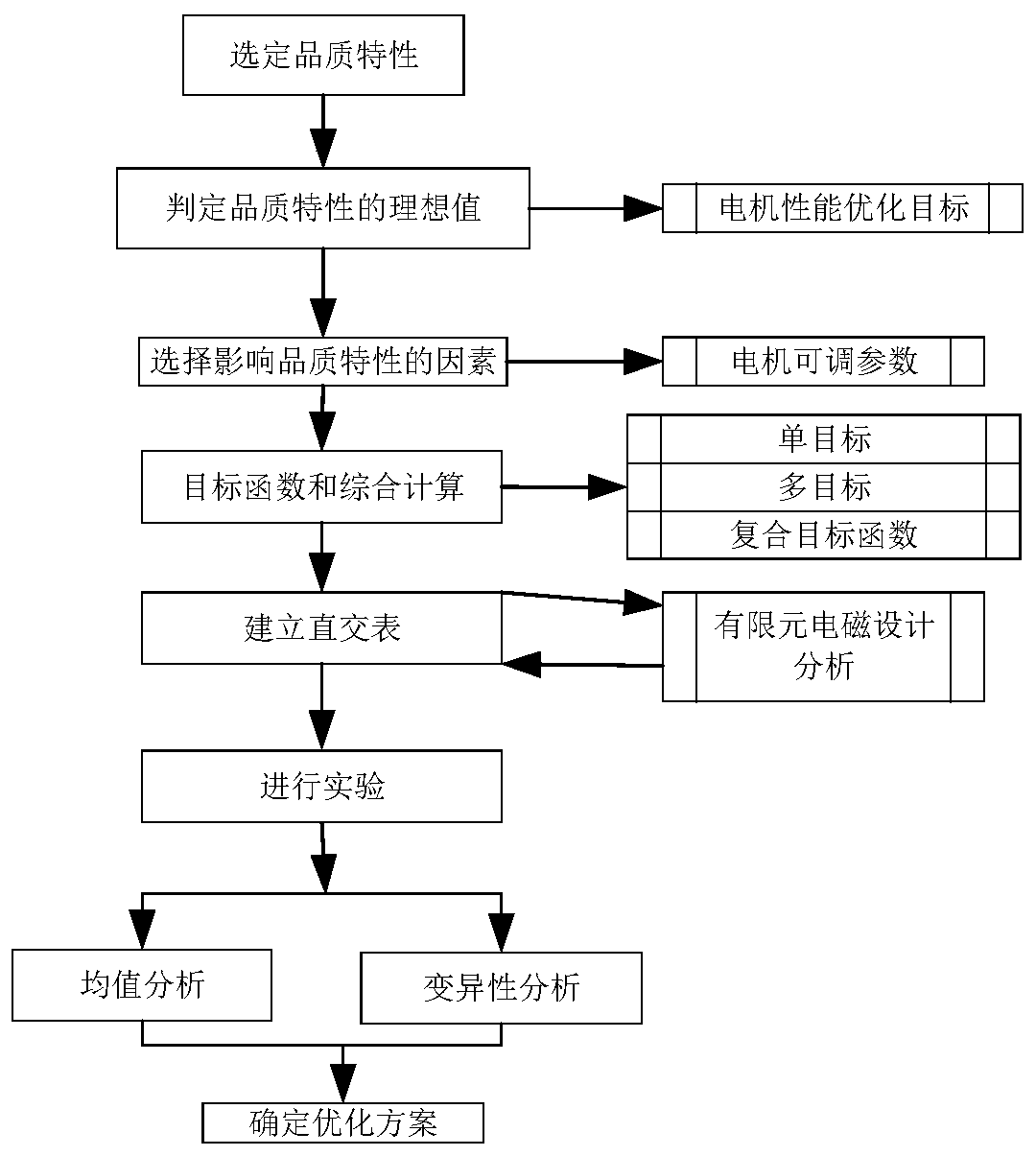

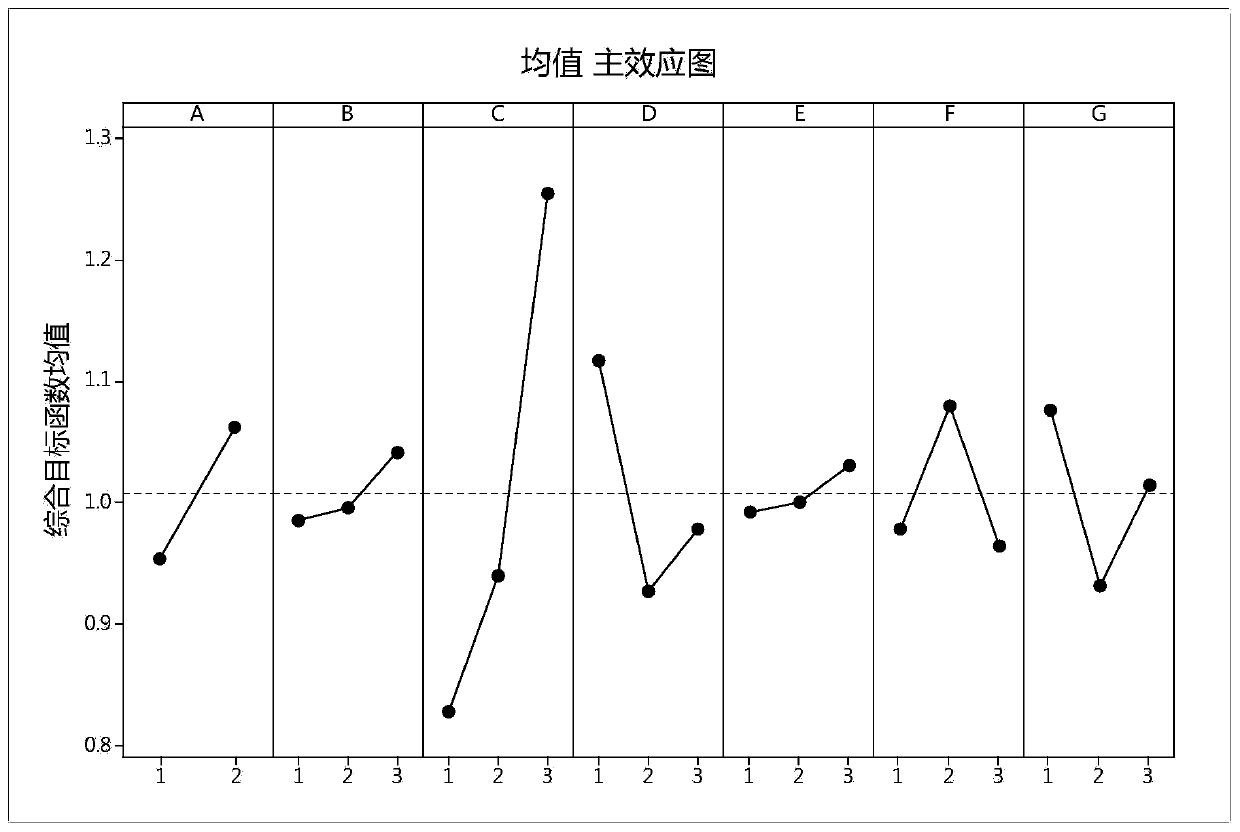

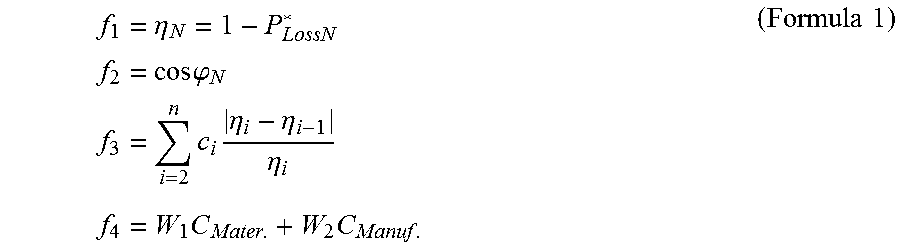

Optimization design method for doubly salient hybrid excitation generator based on Taguchi method

ActiveCN110390157AFavorable for large-scale industrial applicationsReduced number of experimental groupsGeometric CADManufacturing dynamo-electric machinesFast optimizationMean value analysis

The invention discloses a optimization design method for a doubly salient hybrid excitation generator of a Taguchi method, and belongs to the field of doubly salient hybrid excitation generator multi-parameter multi-objective optimization. The method comprises the following steps: (1) selecting quality characteristics of response and judging an ideal value of the quality characteristics; (2) selecting factors influencing quality characteristics; (3) determining an objective function and a comprehensive calculation method; (4) establishing an orthogonal table; (5) carrying out an experiment; and (6) performing mean value analysis and variability analysis to confirm an optimal design scheme. Compared with the traditional number of parameterized simulation experiment groups, the method has the advantages that the number of experiment groups is greatly reduced, the design period is greatly shortened, optimization efficiency is greatly improved, and the large-scale industrial application ofthe motor is facilitated. Compared with a traditional magnetic circuit method for designing a motor, design precision is high, and errors are small; and the method has good portability and is convenient for further rapid optimization of industrial products.

Owner:ZHEJIANG UNIV

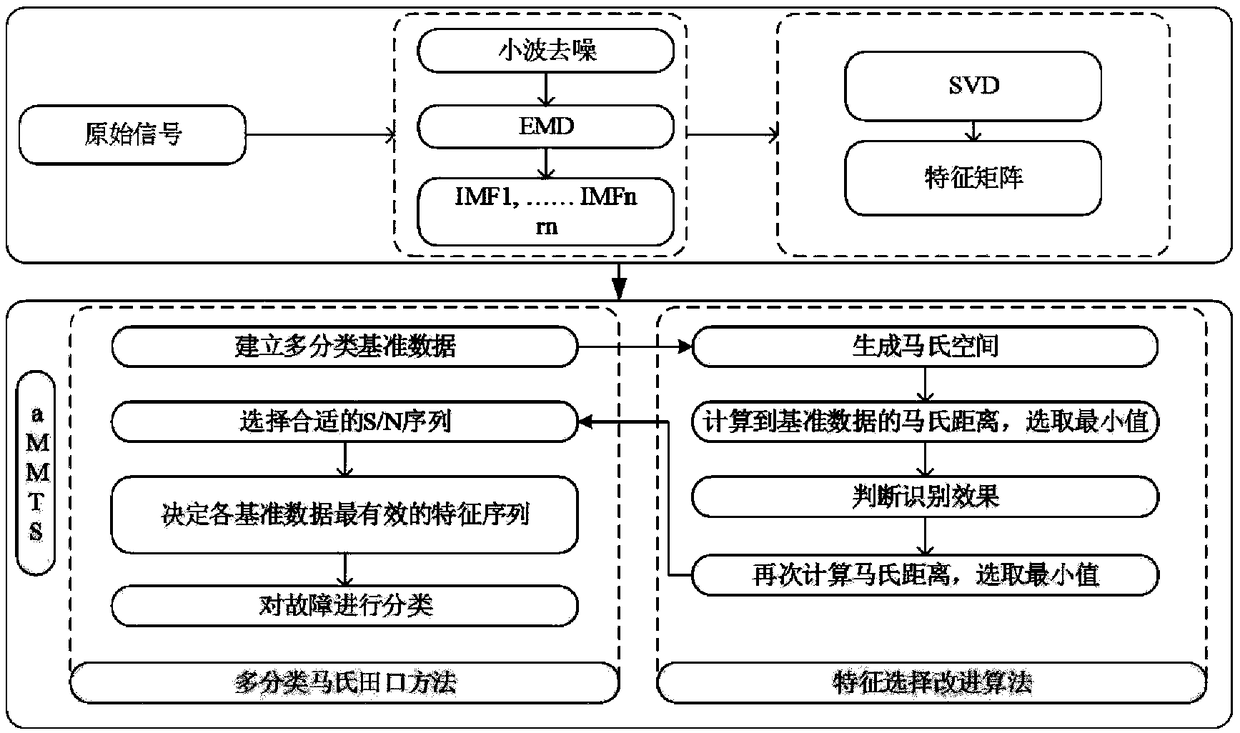

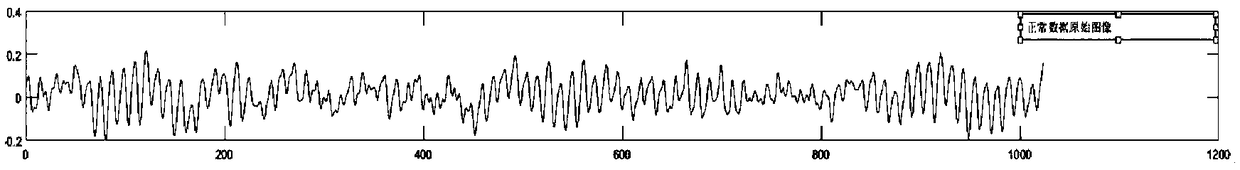

Fault diagnosis method of rotating machinery based on adaptive multi-classified Markov Taguchi method

ActiveCN109297711ATo achieve the purpose of extracting the essence of the signalGuaranteed robustnessMachine part testingFeature vectorWavelet denoising

The invention relates to a fault diagnosis method of rotating machinery based on an adaptive multi-classified Markov Taguchi method. The fault diagnosis method comprises: first, performing wavelet denoising and EMD to decompose the rotating mechanical vibration signal into multiple intrinsic mode functions (IMF); then, subjecting the initial feature matrix of each IMF component to singular value division using SVD, and taking the obtained singular value as a feature vector of a signal; finally, adaptively improving the multi-classified Markov Taguchi method, and using the new method as a classifier for fault diagnosis. The method of the invention can accurately identify and classify faults, and has high recognition accuracy, and the method is reliable.

Owner:BEIJING JIAOTONG UNIV

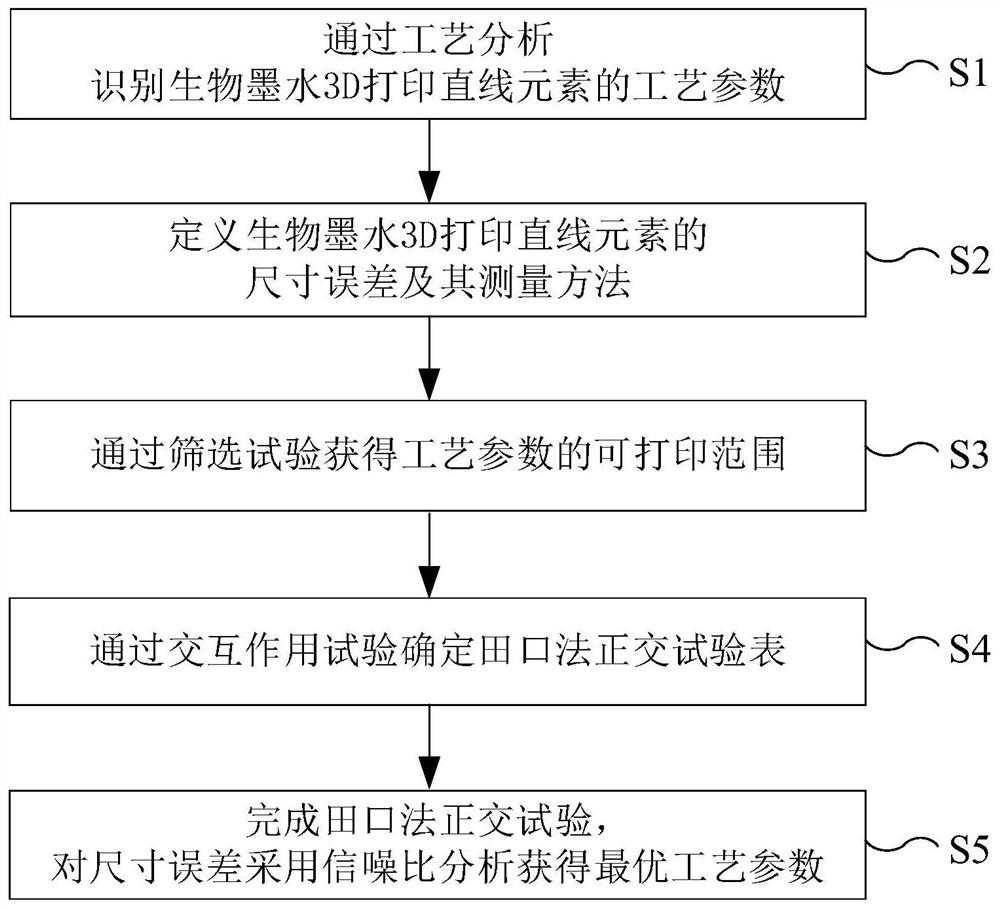

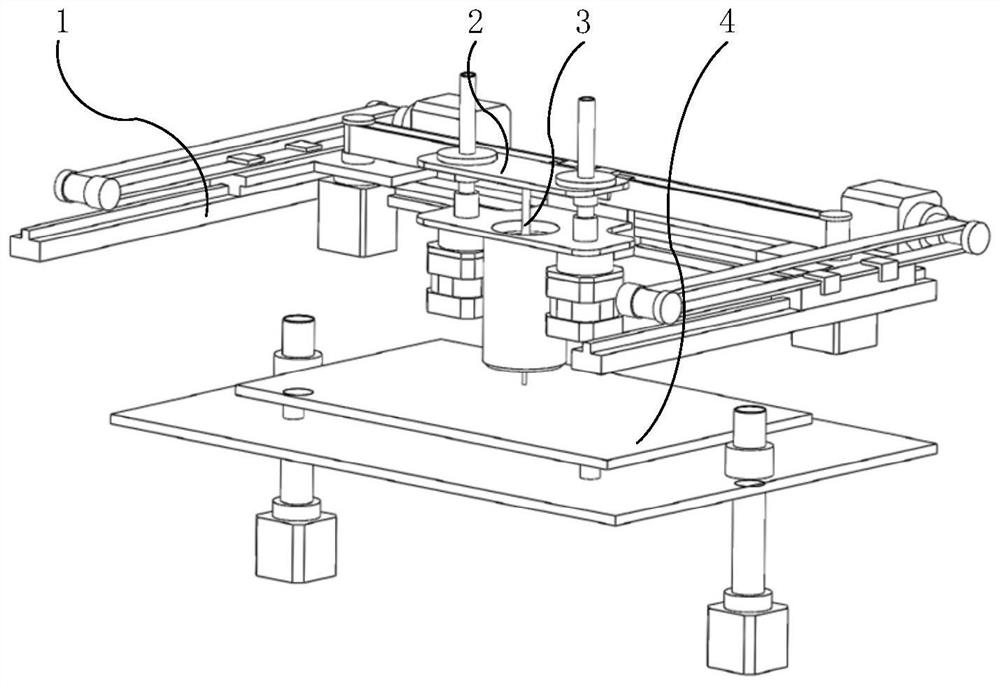

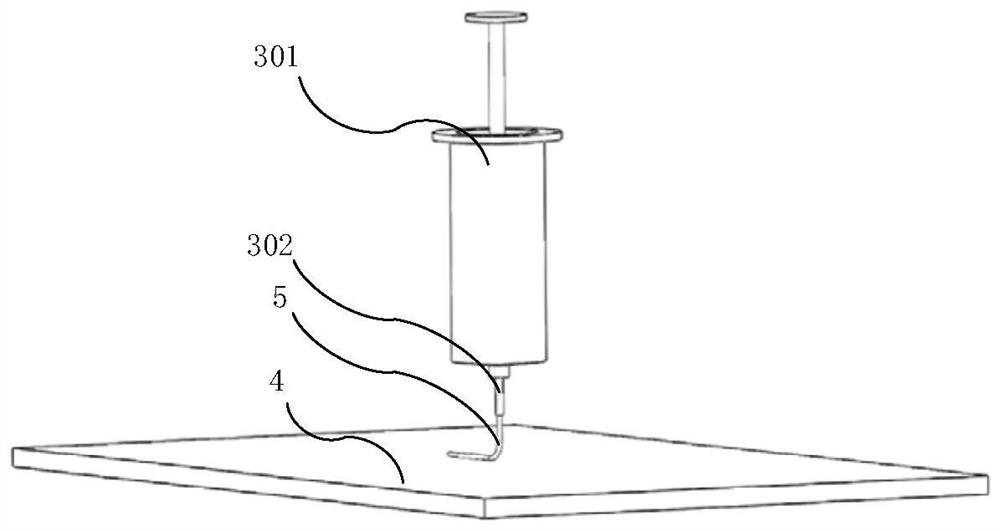

Bio-ink 3D printing straight line element process parameter optimization method

ActiveCN113427766AThe process parameter optimization method is convenientAdditive manufacturing apparatusManufacturing data aquisition/processingComputer printingProcess engineering

The invention discloses a bio-ink 3D printing straight line element process parameter optimization method, which comprises the following steps: S1, determining process parameters influencing the bio-ink 3D printing straight line element effect by analyzing a 3D printing process; S2, defining a size error of a bio-ink 3D printing straight line element and a measurement method of the bio-ink 3D printing straight line element; S3, obtaining a printable range of each process parameter through a screening test; S4, determining a Taguchi method orthogonal test table through an interaction test; S5, completing a Taguchi method orthogonal test, and performing signal-to-noise ratio analysis on a size error to obtain an optimal process parameter. According to the process parameter optimization method, the optimal process parameter combination can be conveniently, quickly, accurately and reliably obtained when different bio-inks and / or extrusion type 3D printers are tried to carry out bio-ink 3D linear element printing.

Owner:厦门天宇丰荣科技有限公司

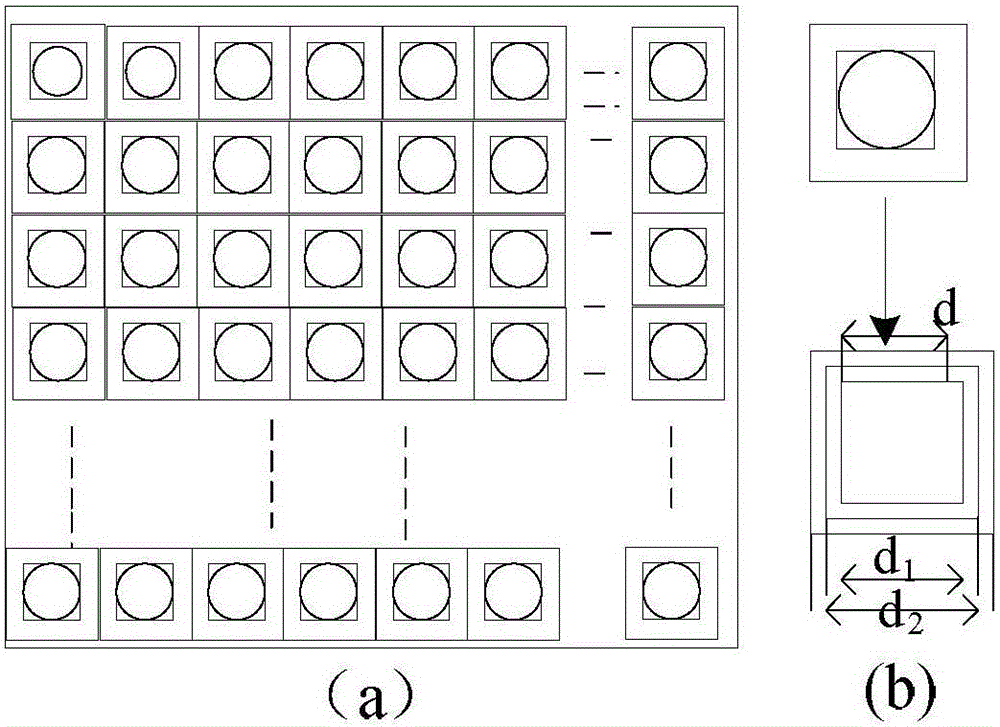

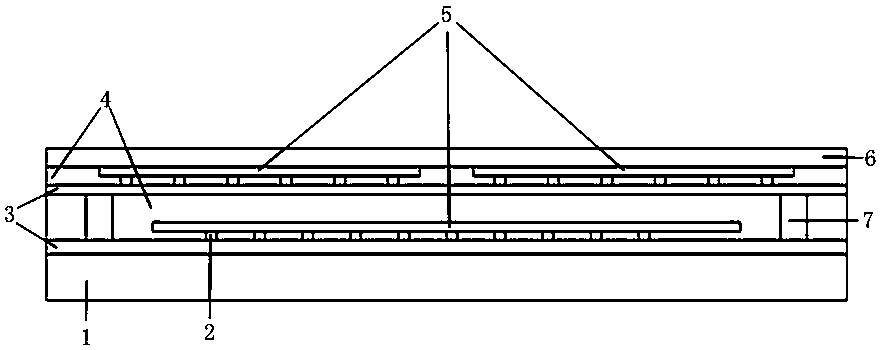

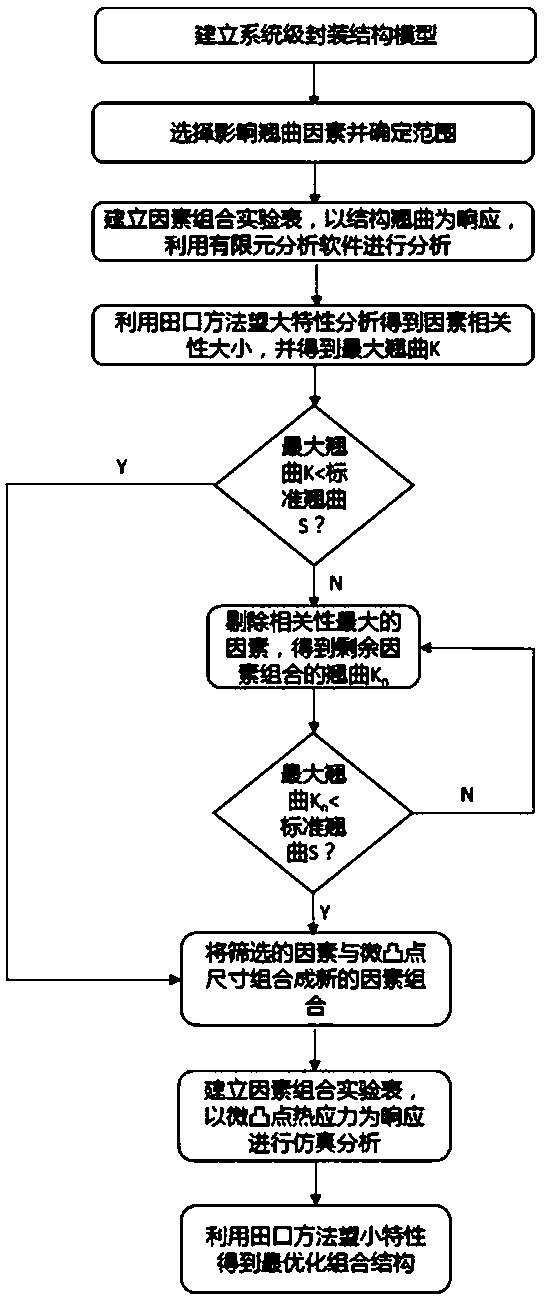

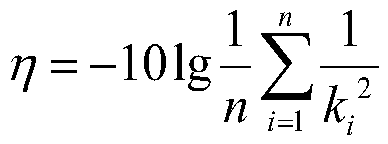

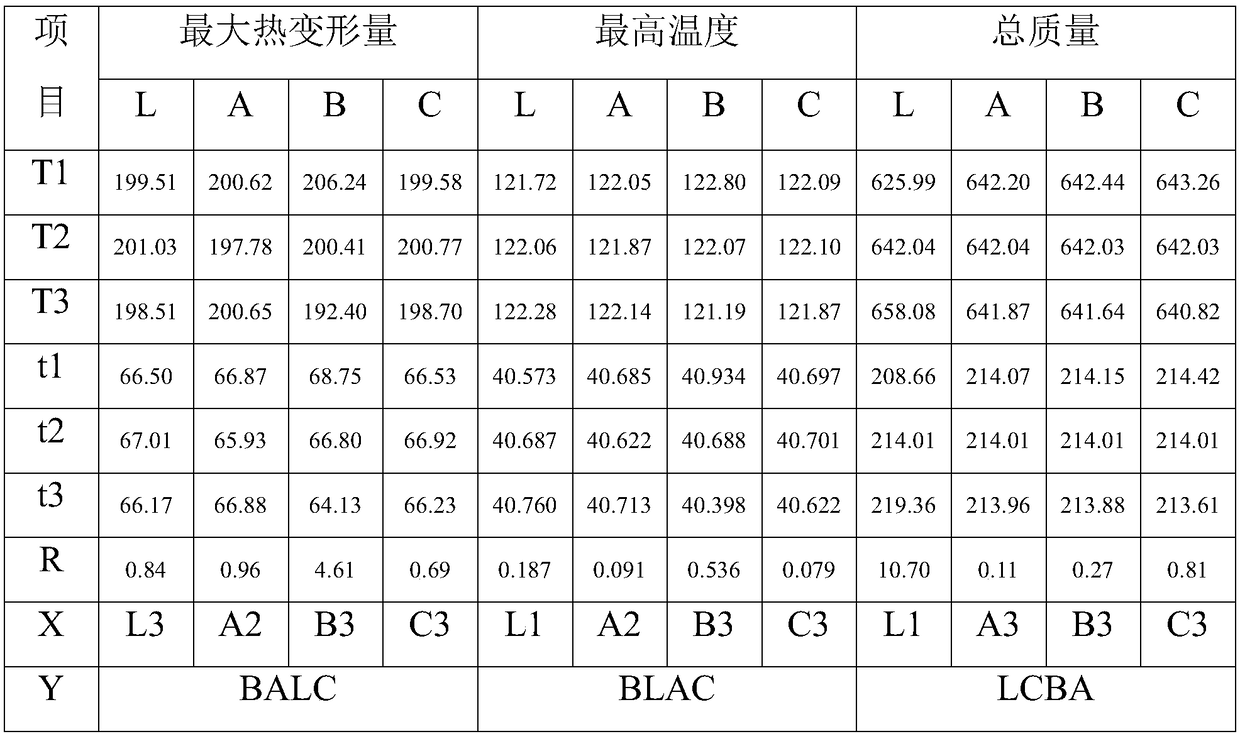

System-in-package thermal reliability comprehensive optimization design method

ActiveCN110442969AImprove thermal reliabilitySimple structureSpecial data processing applicationsCombined testSystem in package

The invention discloses a system-in-package thermal reliability comprehensive optimization design method. The method belongs to the technical field of system-in-package, and is characterized by comprising the following steps: establishing a system-in-package structure model, selecting factors and levels influencing warping to establish a combined test table, analyzing by taking structure warping as a response, and utilizing screening factor combinations of a Taguchi method larger-the -better characteristics to ensure the thermal reliability of the structure warping; combining the factors included in the screening result influencing warping with the sizes of the micro-bumps, establishing a new combination test table, analyzing, taking the thermal stress of the micro-bumps as a response, obtaining an optimal combination structure by using a Taguchi method smaller-the-better characteristic, and completing the comprehensive optimization design of the system-in-package thermal reliability.The warping of the system-in-package structure is taken as a reference, on the premise of ensuring the warping reliability, the thermal reliability of the micro-bumps of the system-in-package structure is optimized and analyzed by utilizing the minimization characteristic of the Taguchi method, a final optimized structure is obtained, and the thermal reliability of the system-in-package structureis improved.

Owner:XIDIAN UNIV

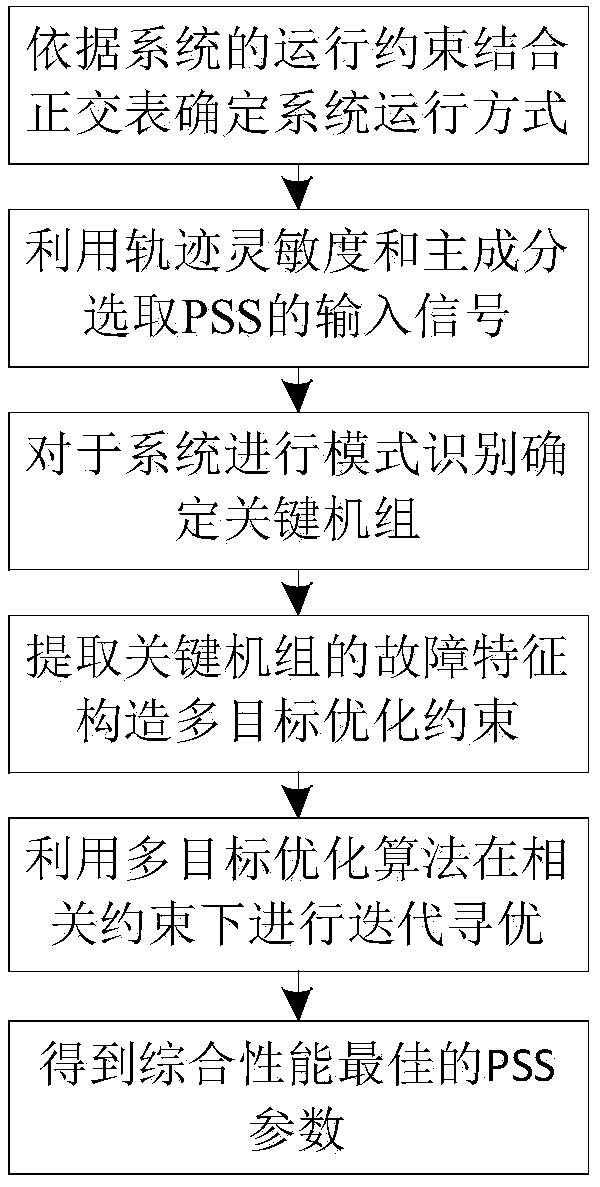

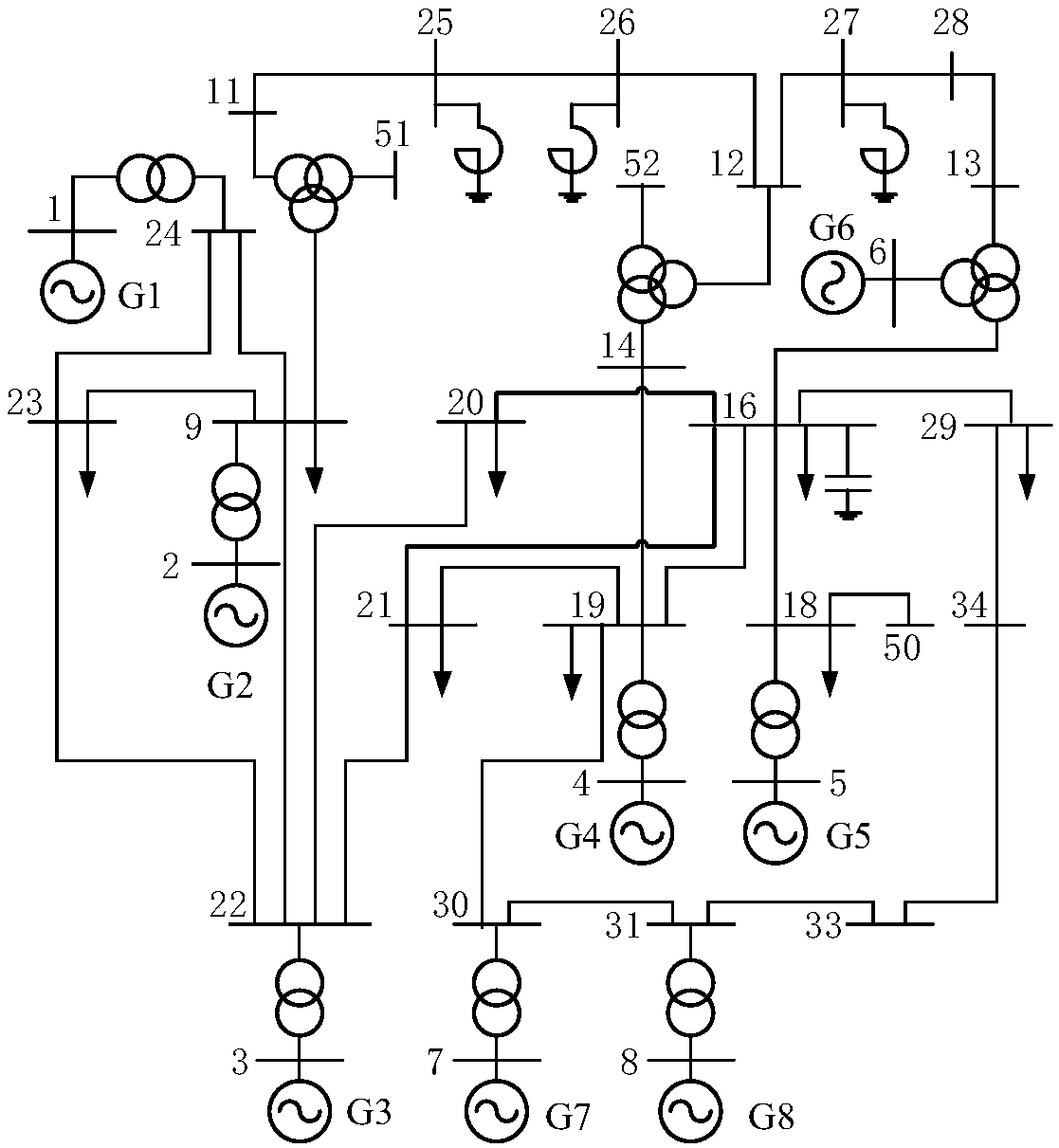

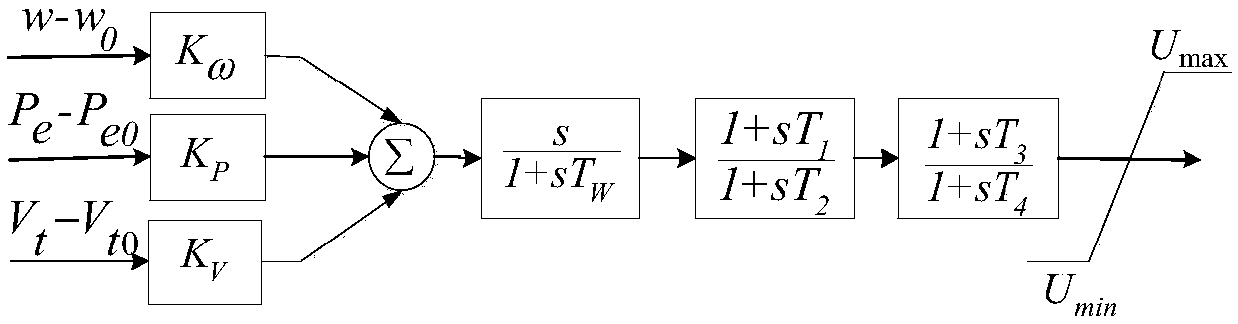

Coordinated optimization method for multi-machine PSS parameters under multiple operation modes

ActiveCN107658865AIncrease the robustness indexGood damping propertiesFlicker reduction in ac networkPower oscillations reduction/preventionRobustificationMulti objective optimization algorithm

The invention discloses a coordinated optimization method for multi-machine PSS parameters under multiple operation modes. The method comprises the steps of firstly determining operation modes of a system, calculating comprehensive evaluation indexes of input signals of each PSS under multiple operation modes according to the trace sensitivity and principal component analysis, and selecting the signal with the relatively large evaluation index as the input signal of the PSS; carrying out mode recognition on the system to select out key units, extracting fault characteristics of the key units,and constructing a robustness objective and a stability objective by using the extracted fault characteristics and combining an ITAE criterion with a taguchi method, thereby constructing a multi-objective optimization algorithm; and finally carrying out iterative optimization of each PSS according to the constructed multi-objective optimization algorithm to obtain the optimum parameter meeting thestability and the robustness of the system under multiple operation modes. According to the coordinated optimization method, global parameter optimization of the transient process of the system undermultiple machines and multiple operation modes is achieved, the oscillation suppression capacity of the power system stabilizers is improved and the robustness under the multiple operation modes is strengthened.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

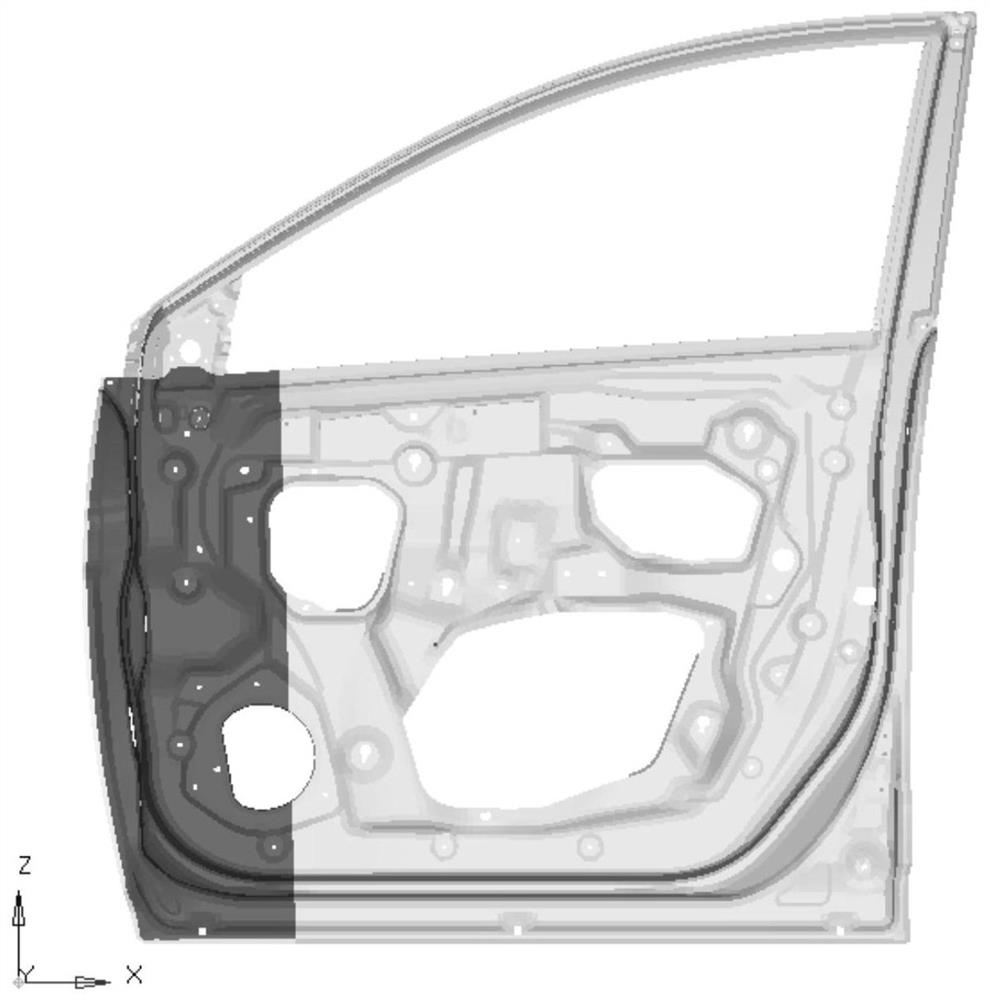

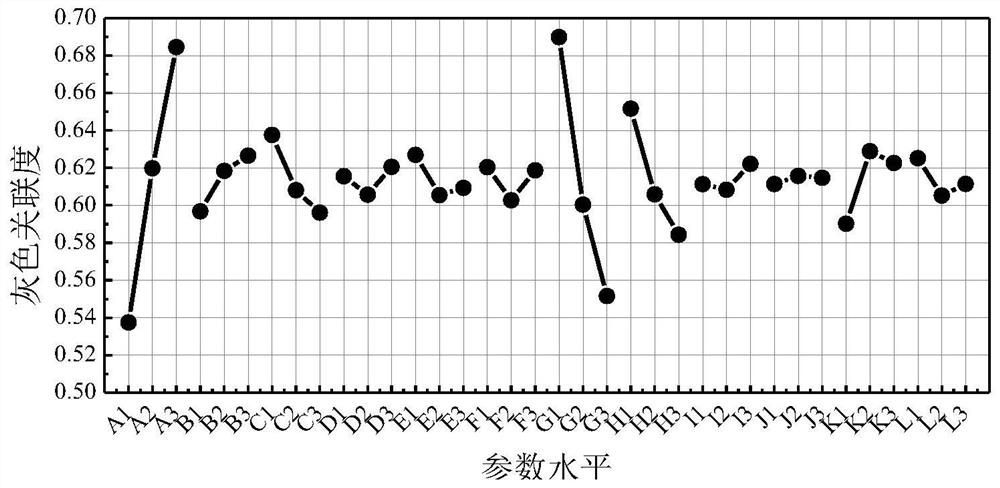

Vehicle door optimization design method based on Taguchi method and entropy weight grey correlation analysis

PendingCN114329788AOptimal structural parametersLightweight effect is goodGeometric CADDesign optimisation/simulationPattern recognitionGrey correlation analysis

The invention provides a vehicle door optimization design method based on a Taguchi method and entropy weight grey correlation analysis, and the method comprises the following steps: S1, building a vehicle door finite element model, verifying the effectiveness of the finite element model, and determining a design variable and an optimization target; s2, carrying out an orthogonal test according to the design variable table and the optimization target; s3, establishing a target response data matrix, and performing Taguchi analysis; s4, performing linear normalization processing on the signal-to-noise ratio sequence of each response; s5, performing gray correlation analysis to obtain a gray correlation coefficient sequence corresponding to each response; s6, calculating the weight value of the grey correlation coefficient sequence of each response and the grey correlation degree sequence of the comprehensive response; s7, calculating the average value of the sum of the grey correlation degree sequences corresponding to each level of each factor; and S8, according to an entropy weight method, calculating each response weight, and determining an optimal variable combination. According to the vehicle door optimization design method, the vehicle door structure optimization design scheme with good performance can be accurately and rapidly output.

Owner:WUHAN UNIV OF TECH

A performance evaluation and prediction method of mechanical wear parts based on emd-svd and mts

InactiveCN103674511BSave math featuresImprove real-time performanceMachine part testingFeature vectorSingular value decomposition

The invention provides a mechanical wearing part performance assessment and prediction method based on based on EMD (empirical mode decomposition)-SVD (singular value decomposition) and an MTS (Mahalanobis-Taguchi system), and belongs to the technical field of mechanical wearing part fault diagnosis. The method comprises: first of all, performing noise reduction processing on acquired signals of a monitored object, then performing EMD on the signals, selecting effective IMF (intrinsic mode function) components and residual functions to form an initial matrix, performing SVD on the initial matrix, and performing normalization processing on obtained characteristic values to obtain characteristic vectors; then using an MTS method to calculate an MD (Mahalanobis Distance), and using a Taguchi method to perform optimization and reduction on the characteristic vectors; and converting the MD into a confidence value, performing assessment on the performance of mechanical wearing parts through tracking the trend of the confidence value, and performing prediction on a fault through a correlation module or a matching matrix between the confidence value and conditions of the monitored object. The method provided by the invention avoids the problem of easily occurring errors when a conventional method is used for processing non-linear non-stationary signals, and reduces fault generation probability, thereby being suitable for industrial real-time monitoring.

Owner:BEIHANG UNIV

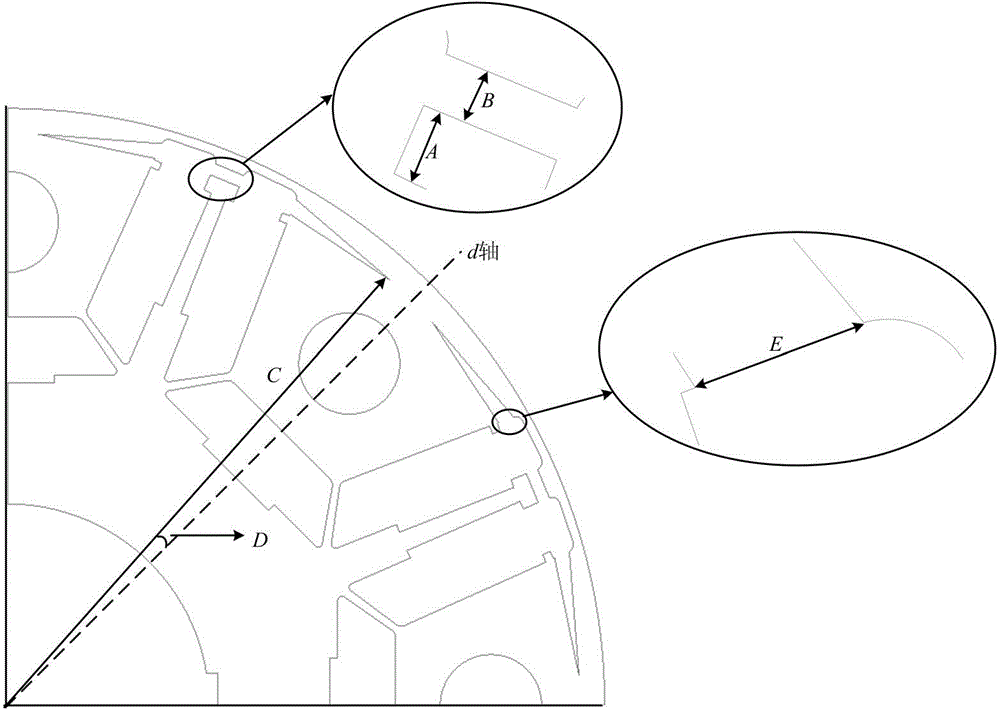

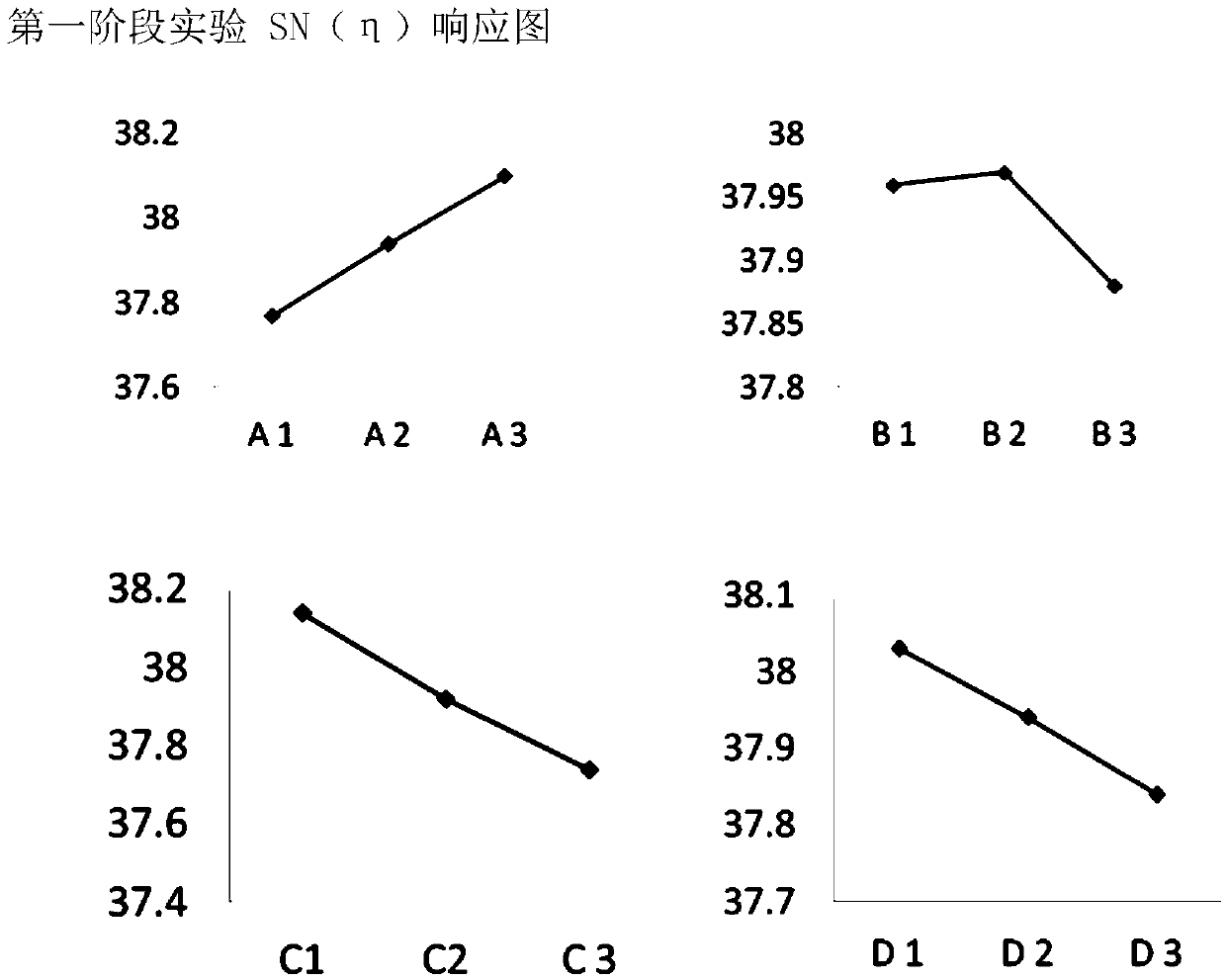

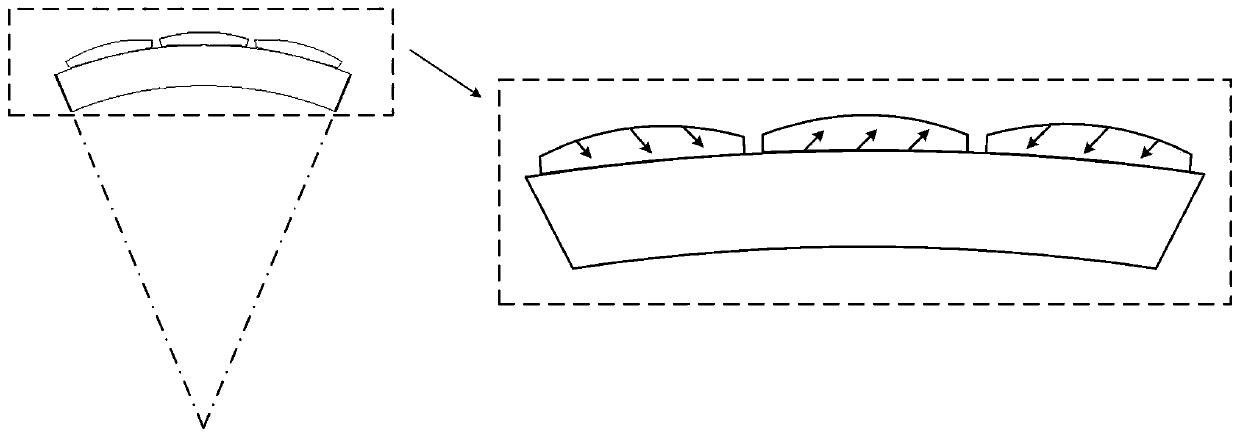

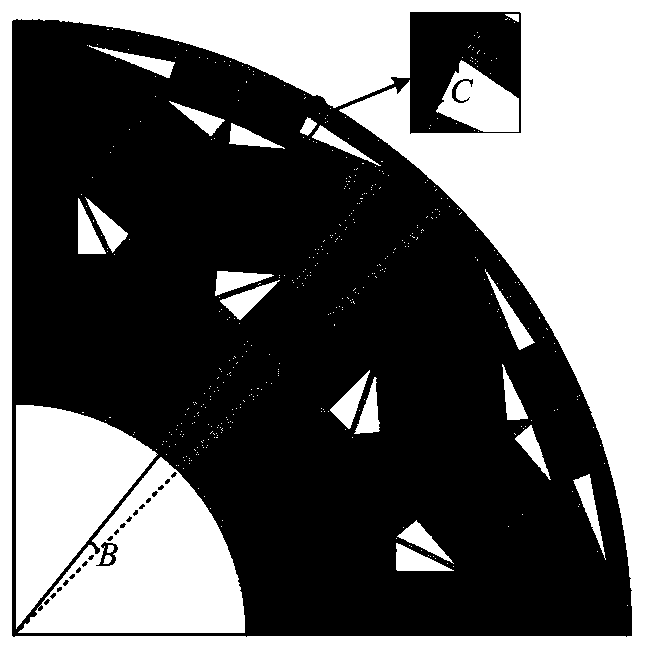

Fractional-slot SPMSM magnetic pole structure optimization design method for reducing unbalanced magnetic pull

ActiveCN111262409ALow balanceReduce torque fluctuationMagnetic circuit rotating partsSynchronous machine detailsPull forceElectric machine

The invention relates to a fractional-slot SPMSM magnetic pole structure optimization design method for reducing unbalanced magnetic pull. The method comprises the following steps of: determining theinitial magnetic pole structure of a motor to be a 90-degree parallel magnetized equal-thickness magnetic pole structure; providing the magnetic pole improvement scheme of the motor, and adopting a magnetizing direction-changed unequal-thickness magnetic pole structure; selecting a Taguchi method as a magnetic pole structure optimization design. According to the Taguchi method, the pole-arc coefficient of original magnetic poles, namely an optimization variable A, the distance of the deviation of the outer arc centers of the magnetic poles from the center of the motor, namely an optimization variable B, a magnetizing direction, namely an optimization variable C and different magnetic pole shapes, namely an optimization variable D are used as optimization variables, and torque ripple reduction and unbalanced magnetic pull reduction are used as optimization objectives. According to the method, the influence of the change of each optimization variable on unbalanced magnetic pull, torque ripple and result robustness is analyzed; the magnetic pole structure of a fractional-slot SPMSM is optimized; the unbalanced magnetic pull and torque ripple of the motor can be effectively reduced byusing the optimized structure, and the operation stability of the motor is improved.

Owner:TIANJIN POLYTECHNIC UNIV

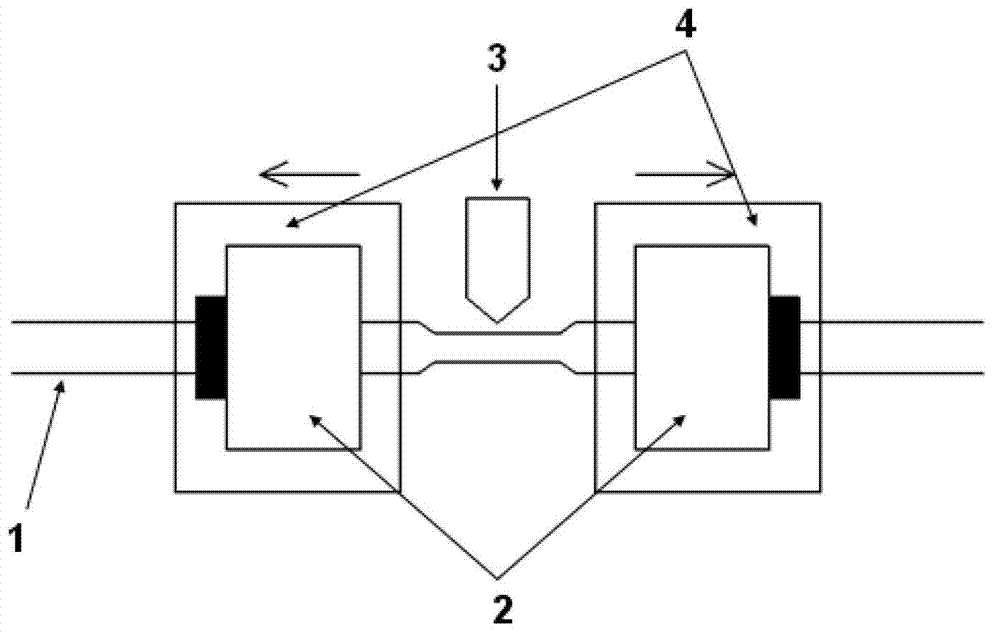

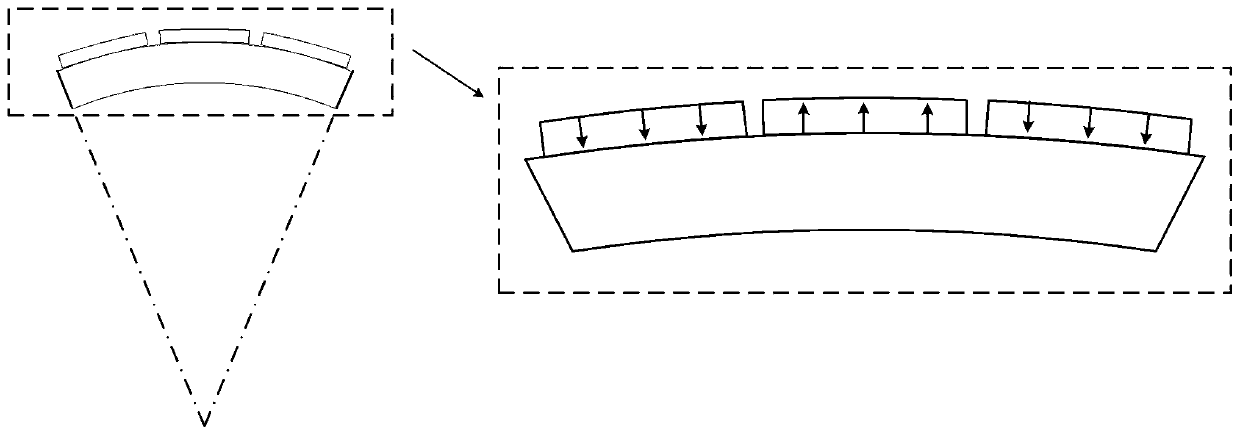

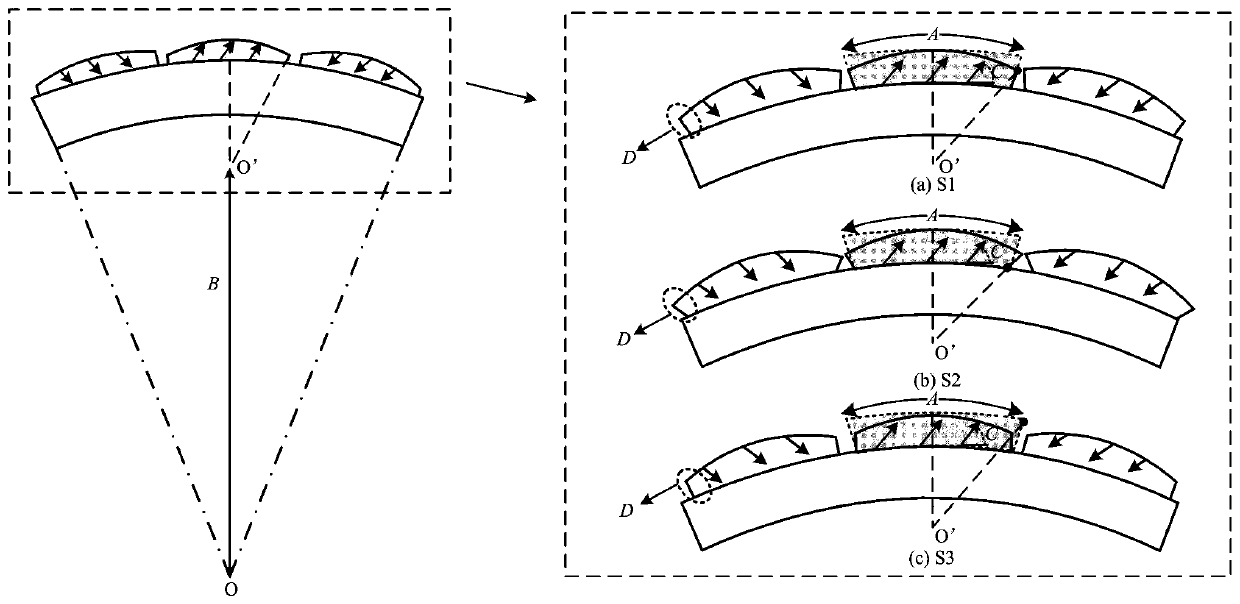

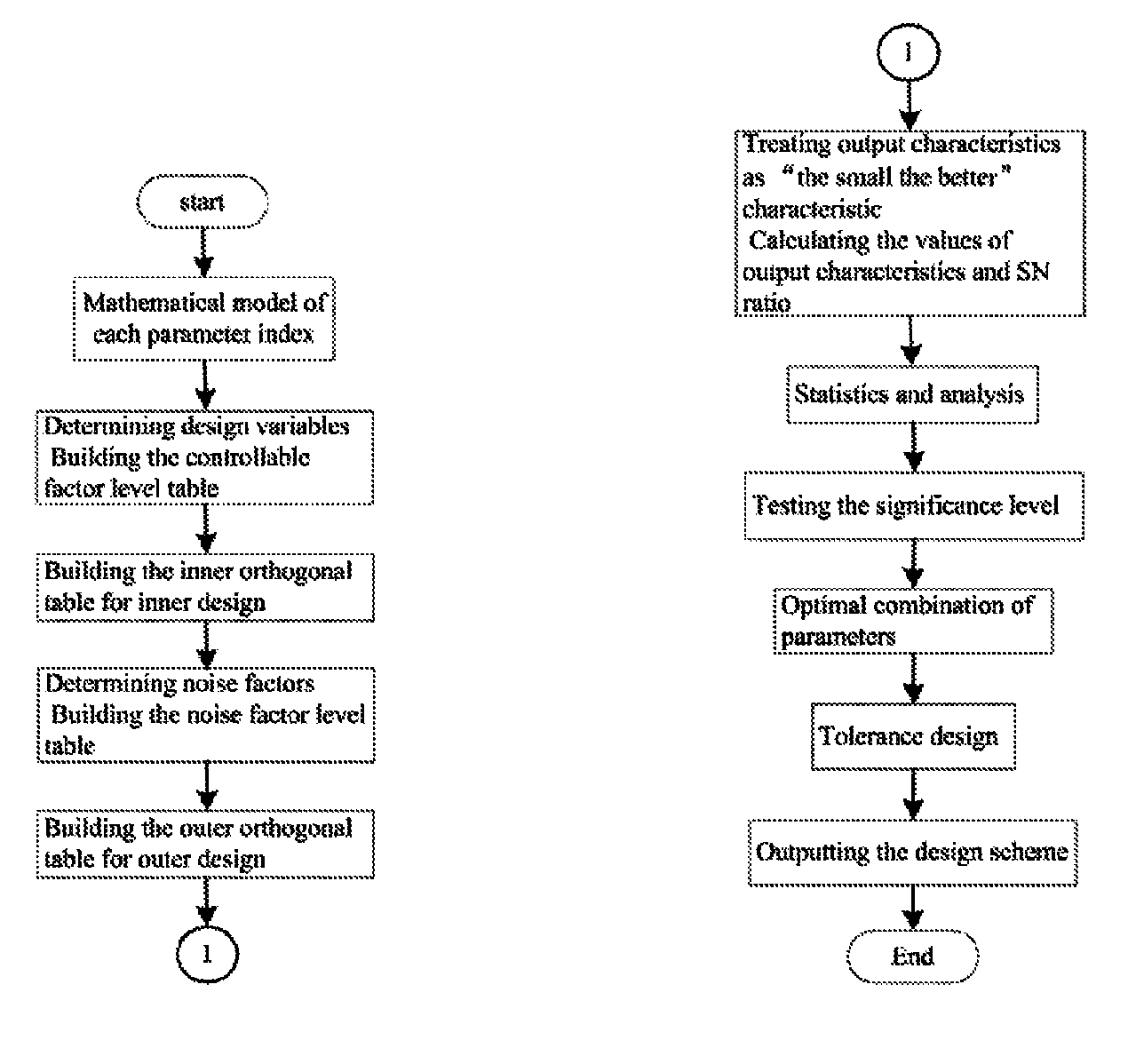

Robust design method for a textile-manufacturing-dedicated, high-efficient, energy-saving, multiphase asynchronous motor

ActiveUS9348951B2Improve efficiencyIncrease powerAerodynamics improvementComputer aided designTextile manufacturingElectric machinery

Robust design method for a textile-manufacturing-dedicated multiphase asynchronous motor, including the steps: designing a motor with design variables for a high-efficient, energy-saving, multiphase asynchronous motor; selecting a number of controllable variables and their level values to build an inner orthogonal table; selecting a number of noise factors and their level values to build an outer orthogonal table; using a Taguchi method, determining the optimal combination of level values of the controllable variables and corresponding values ranges for a tolerance design, resulting in an optimal design scheme; producing technical drawings for each parts of the motor according to the optimal design scheme and producing a physical motor; comparing the performance of the physical motor with the predetermined performance target and repeating the above steps as many times as necessary until the performance target is met and the motor achieves the optimal balance between the quality and cost.

Owner:TIANJIN POLYTECHNIC UNIV

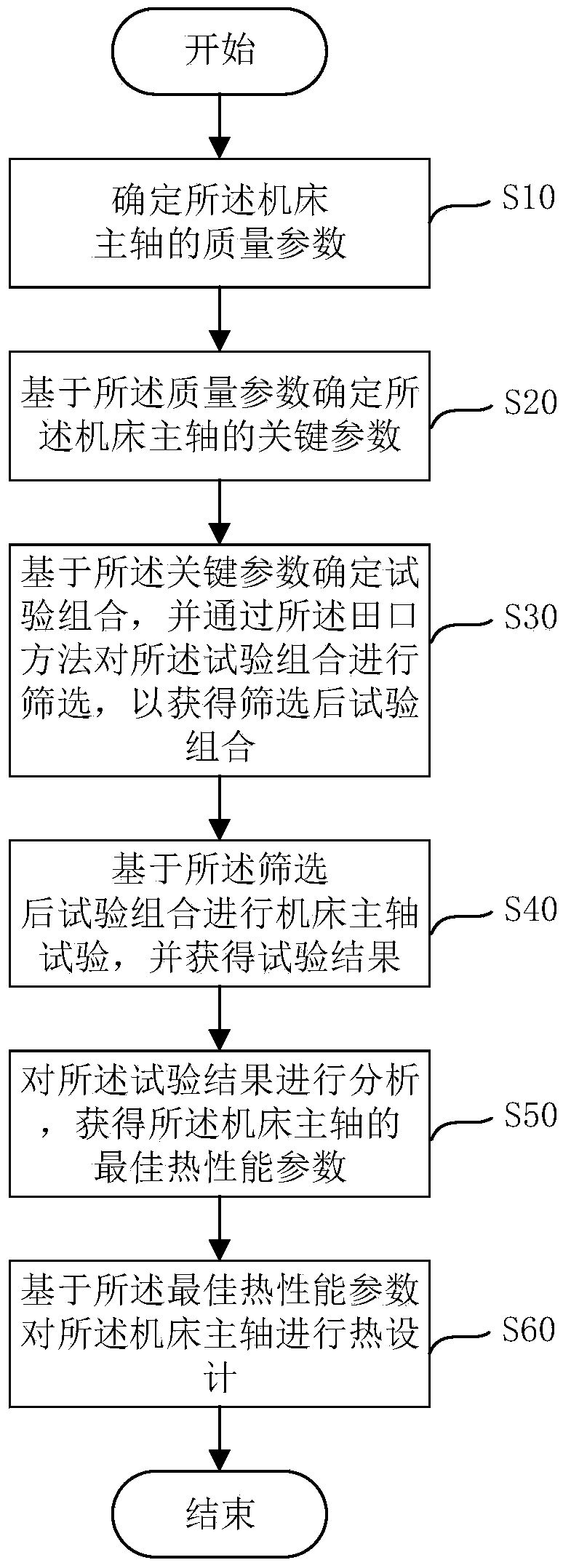

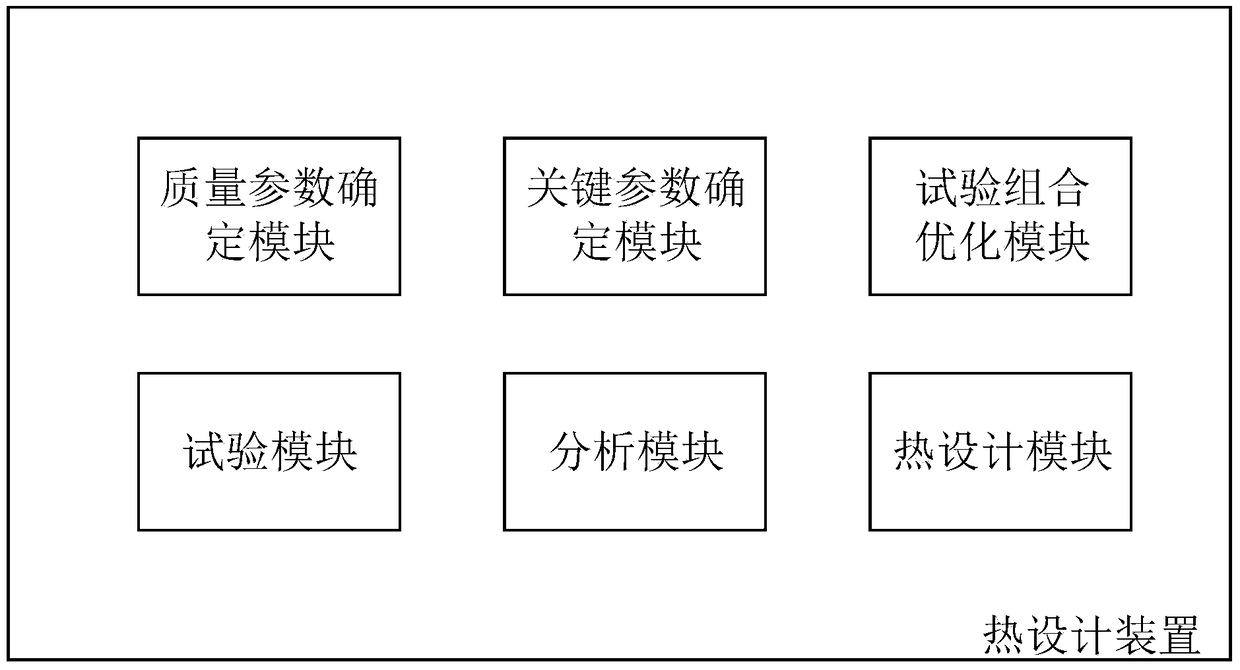

Taguchi method-based thermal-optimization method of machine tool spindle

ActiveCN108763682AEasy accessFull accessGeometric CADDesign optimisation/simulationEngineeringMachine tool

The invention discloses a Taguchi method-based thermal-optimization method of a machine tool spindle. The method includes: determining quality parameters of the machine tool spindle; determining key parameters of the machine tool spindle on the basis of the quality parameters; determining test combinations on the basis of the key parameters, and screening the test combinations through a Taguchi method to obtain a test combination after screening; carrying out a machine tool spindle test on the basis of the test combination after screening, and obtaining a test result; analyzing the test resultto obtain optimal thermal performance parameters of the machine tool spindle; and carrying out thermal optimization on the machine tool spindle on the basis of the optimal thermal performance parameters. The invention also discloses a thermal-optimization device of the machine tool spindle on the basis of the Taguchi method. Through using the Taguchi method to screen the test combinations in an optimization process, the better test combination is selected for a test, computational complexity in the optimization process is reduced, and thus the machine tool spindle is more quickly, more comprehensively and more accurately optimized.

Owner:QUZHOU UNIV

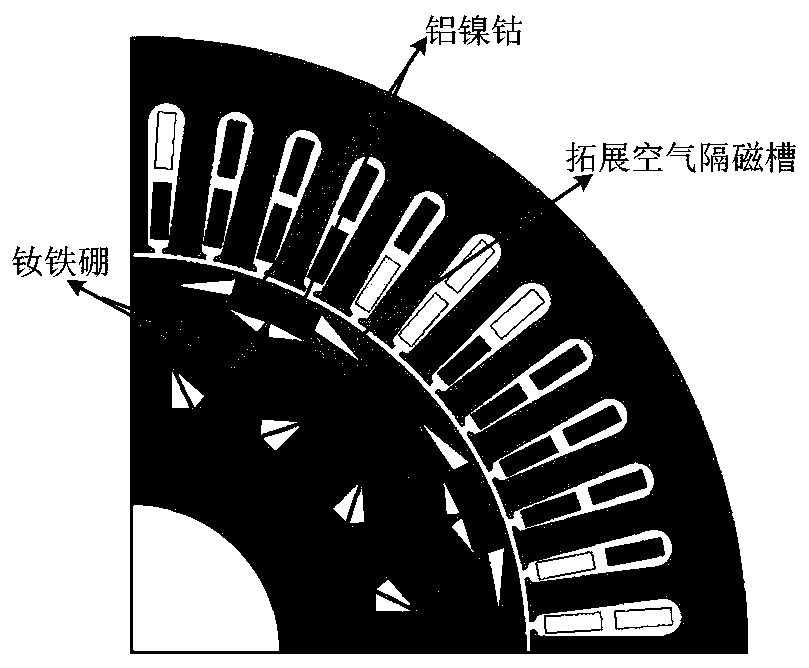

Low-iron-loss variable flux permanent magnet memory motor robustness design method for electric automobile

PendingCN110739821AReduce iron consumptionReduce harmonic componentsSynchronous machine detailsMagnetic circuit rotating partsMagnetic polesElectric machinery

The invention relates to a low-iron-loss variable flux permanent magnet memory motor robustness design method for an electric automobile. The method comprises steps that a variable flux permanent magnet memory motor structure for the electric vehicle is determined; an air magnetic isolation groove structure of an improved variable flux permanent magnet memory motor is improved, air magnetic isolation groove expansion structures are added to air magnetic isolation grooves on two sides of a U-shaped permanent magnet cavity close to a surface of a rotor core, and sharp points of the air magneticisolation groove expansion structures in a rotor pole shoe are defined as vertexes of the expansion structures; a distance from the vertex of the air magnetic isolation groove expansion structures tothe circle center of the rotor, an included angle between the vertex of the air magnetic isolation groove expansion structure and a center line of a magnetic pole, the width of an edge opposite to thevertex of the air magnetic isolation groove expansion structure and the position of the edge opposite to the vertex of the air magnetic isolation groove expansion structure serve as optimization variables. The method is advantaged in that the minimum flux linkage and the minimum iron loss under the action of demagnetizing current pulses and the minimum iron loss under the action of magnetizing current pulses are taken as optimization objectives, and the improved structures of the air magnetic isolation grooves are optimized by using a Taguchi method.

Owner:TIANJIN POLYTECHNIC UNIV

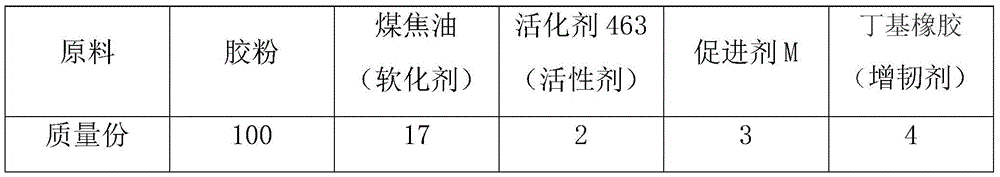

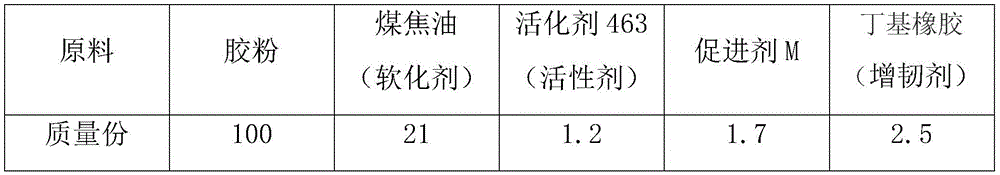

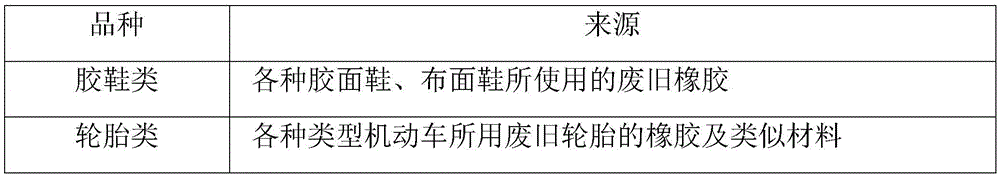

Method for regenerating reclaimed rubber and method for producing rubber rain boots using the reclaimed rubber

InactiveCN103772738BOvercome limitationsGood physical propertiesPlastic recyclingDomestic footwearMicrowave methodEconomic benefits

The invention discloses a reclaiming method of reclaimed rubber and a manufacturing method of rubber rain shoes by using reclaimed rubber. The reclaiming of the reclaimed rubber comprises the following steps of: (a) designing a reclaiming process by adopting a taguchi method; (b) sorting and primarily processing raw materials; (c) cutting rubber; (d) crushing waste and old rubber at a low temperature; (e) treating after crushing; (f) desulfurizing by a microwave method; and (g) processing and treating the reclaimed rubber. Simultaneously, the reclaimed rubber prepared by the reclaimed method is used to produce the rubber rain shoes by the following steps of: (a) designing a production process by adopting the taguchi method; (b) weighing and clearing the raw materials; (c) mixing the raw materials; (d) sulfurizing the rubber; (e) pressing and forming soles; (f) pressing and forming uppers; and (g) bonding and forming. The reclaiming method disclosed by the invention has the advantages that the reclaimed rubber is adopted for replacing the traditional natural rubber and synthetic rubber, and therefore the manufacturing cost of a product is reduced and the considerable economic benefit is brought; the non-reclaimed resources can be reclaimed, so that the environmental pollution is avoided, the energy-saving and environmental-friendly effects are achieved, and the production of the rain shoes steps into economic circle with good circulation.

Owner:浙江佰利鞋业有限公司

Optimum design method of heat sink based on Taguchi method

InactiveCN102646146BResolve uncertaintyShorten the design cycleSpecial data processing applicationsEngineeringDependability

An optimum design method of a heat sink based on the Taguchi method comprises selecting controllable factors and a noise factor; designing an experimental program; performing experiment; analyzing an experimental result; executing the Taguchi method on the experimental result; and finally determining the optimum design by the experiment. The invention adopts simulation combined with Taguchi parameter design, carries out experimental design on relevant parameters of the heat sink, then simulates the heat dissipation effect (power device housing temperature) and heat sink quality by means of simulation method, and analyzes the simulation result, to thereby optimize heat sink parameters and research optimum combination of heat sink parameters. The method has practical value in the technical field of avionic product reliability engineering.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com