Method for regenerating reclaimed rubber and method for producing rubber rain boots using the reclaimed rubber

A technology of reclaimed rubber and rubber, applied in footwear, applications, footwear, etc., can solve the problems of waste of resources, high price, high cost, etc., and achieve the effects of strong pertinence, reduced inspection costs, and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

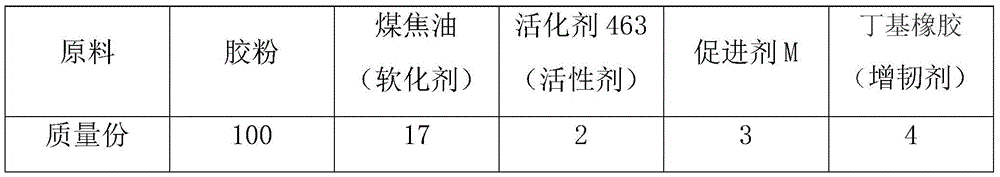

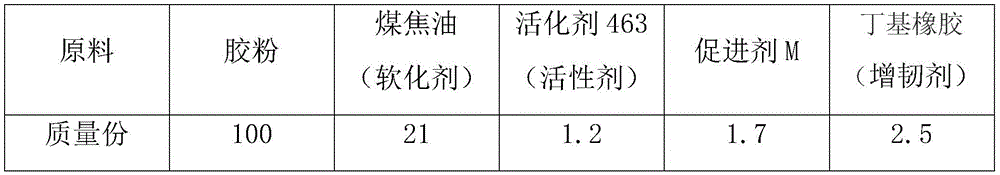

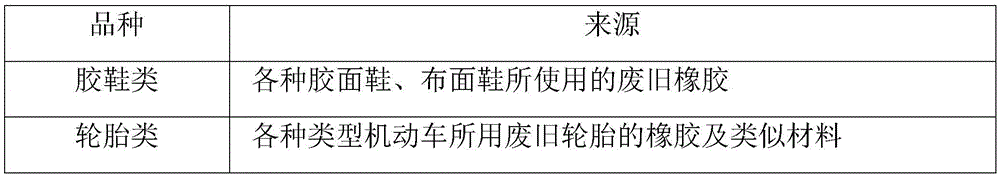

Embodiment Construction

[0041] The regeneration method of the reclaimed rubber and the manufacturing method of the reclaimed rubber used in rubber rain boots of the present invention design the regeneration process and formula through the Taguchi method and the normal distribution test method, and obtain the ideal reclaimed rubber through classification, crushing, desulfurization and refining. Using Taguchi method and normal distribution test method to design the production process and formula of rain boots again, the reclaimed rubber is used as raw material to produce rubber rain boots through mixing, vulcanization, pressing and other steps.

[0042] A regeneration method for reclaimed rubber, characterized in that it comprises the steps of:

[0043] (a) Taguchi method design regeneration process:

[0044] The regeneration process of reclaimed rubber is analyzed comprehensively by Taguchi method. Taguchi method is a low-cost, high-efficiency quality engineering method. It emphasizes that the improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com