Method for determining working current and time of permanent-magnet linear motor based on taguchi method

A permanent magnet linear motor, working current technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of motor heating will not be fully utilized, short-time working time is short, etc., to achieve simple calculation Ease of operation, model simplification, simple and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

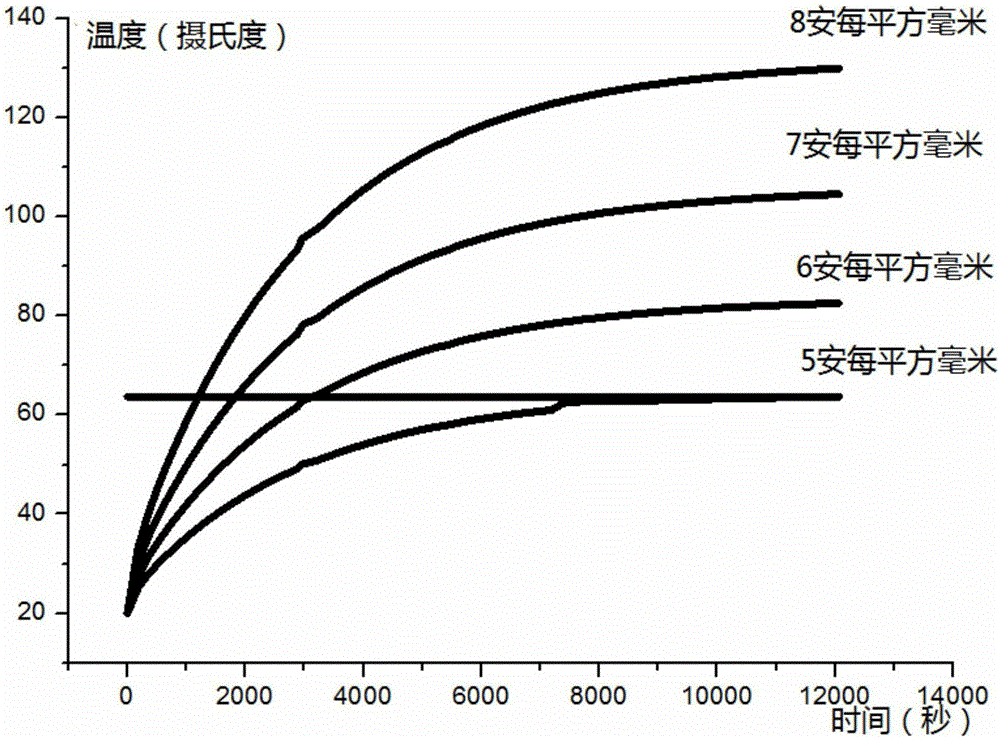

[0036] (1) The temperature rise and cooling test of the test motor is carried out under the condition that the environmental conditions remain unchanged;

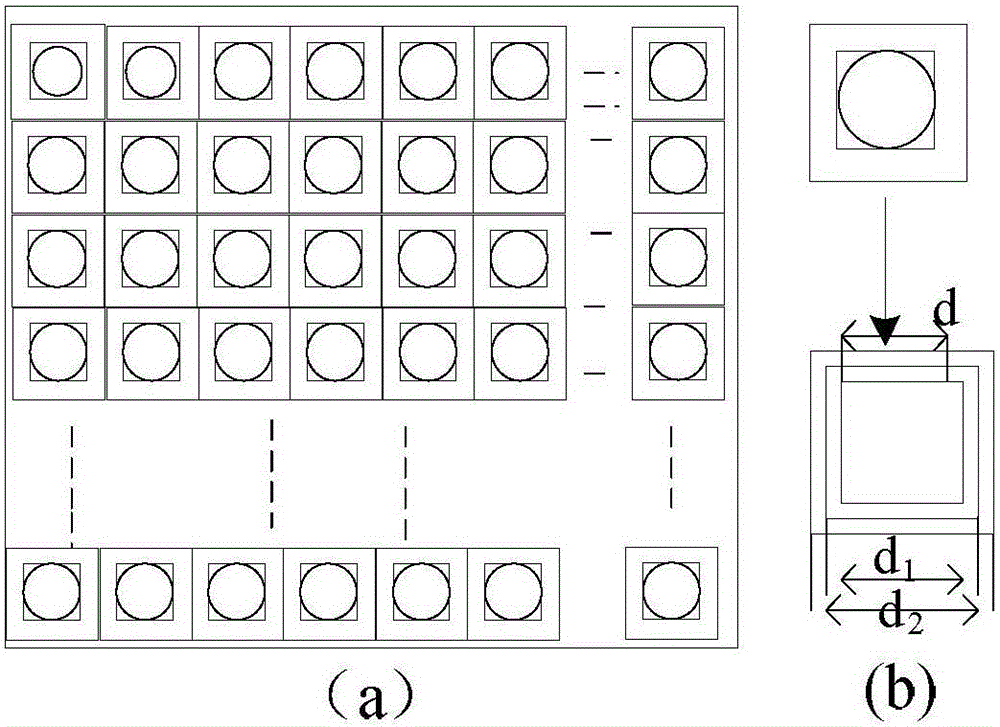

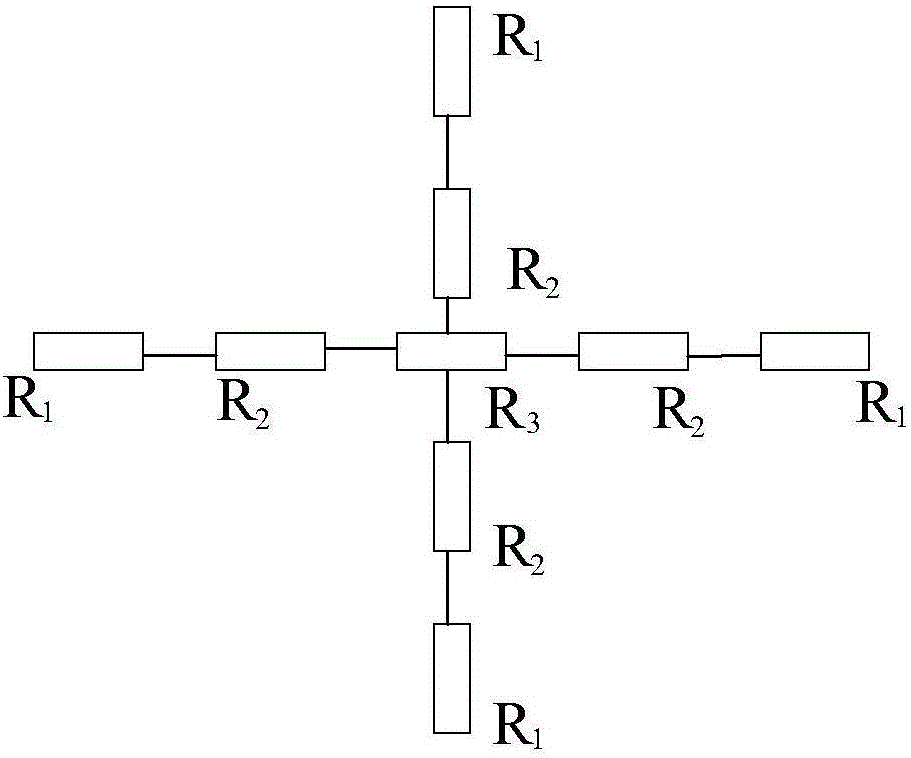

[0037] The experimental instruments include a linear motor, oscilloscope, driver, computer, multi-channel temperature tester, temperature sensor, etc. The experimental process is as follows: under the condition that the environmental conditions remain unchanged, the linear motor is driven by the driver to reciprocate, and the current density of the motor is tested by the oscilloscope during the operation process. The tester records the temperature values of the motor at each set time from startup to stable temperature rise under different current densities.

[0038] The purpose of the experiment is to verify the rationality of the calculation of the parameters in the simulation solution, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com