Method for optimizing parameters of laser cladding process on plane

A technology of process parameter optimization and laser cladding, which is applied in the direction of metal material coating process and coating, can solve the problems of inability to express, lack of standards for parameter optimization, and inability to select, so as to achieve the effect of improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

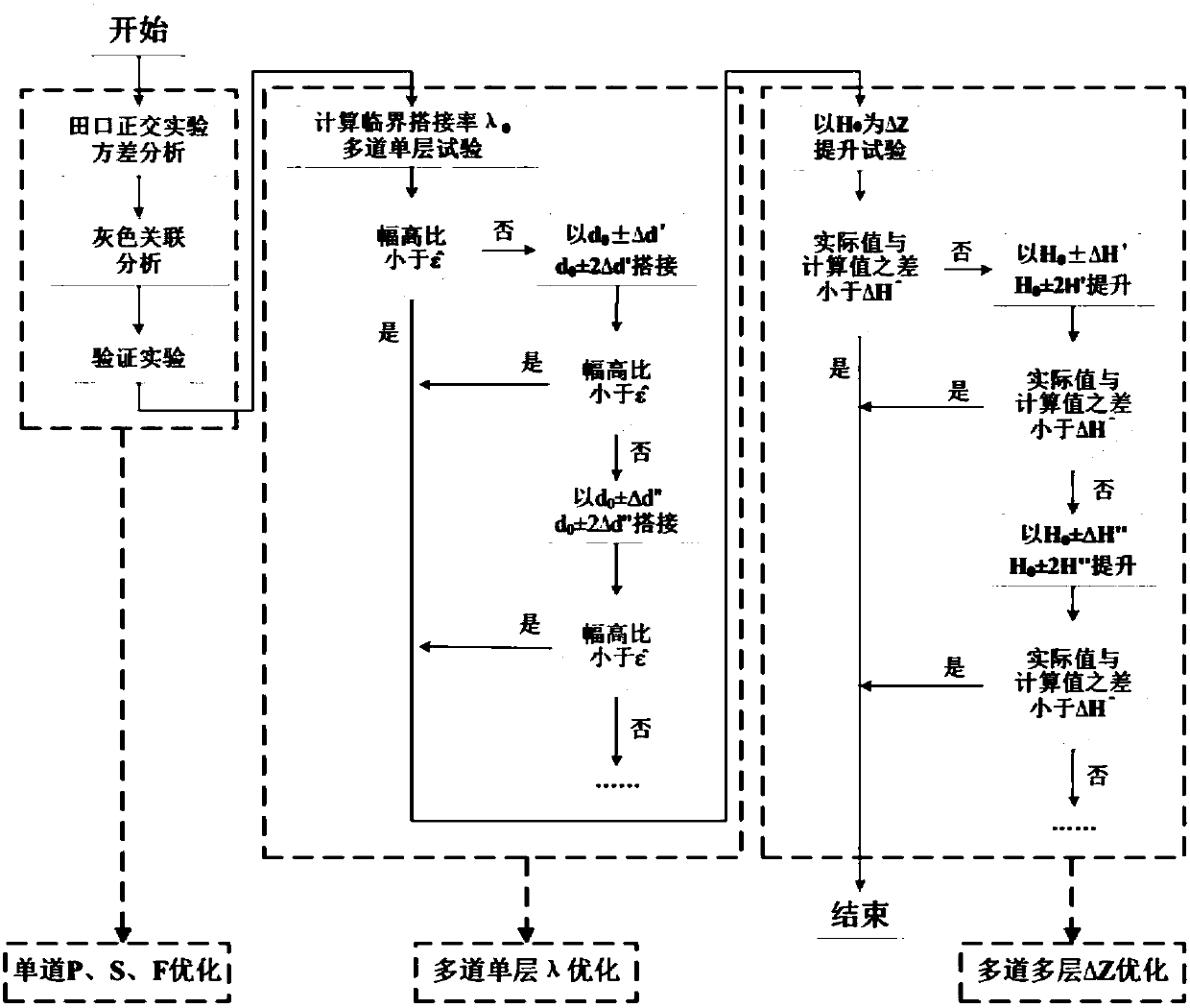

[0041] refer to figure 1 , this embodiment provides a method for optimizing process parameters of laser cladding on a plane, which specifically includes the following steps:

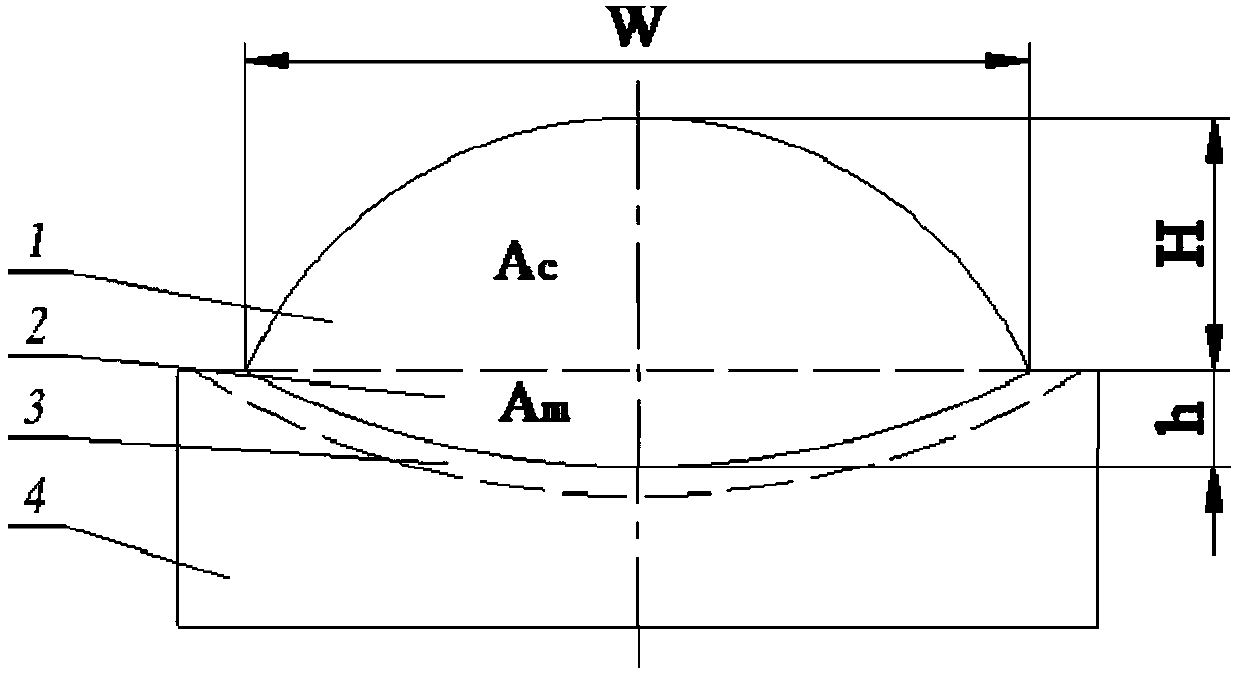

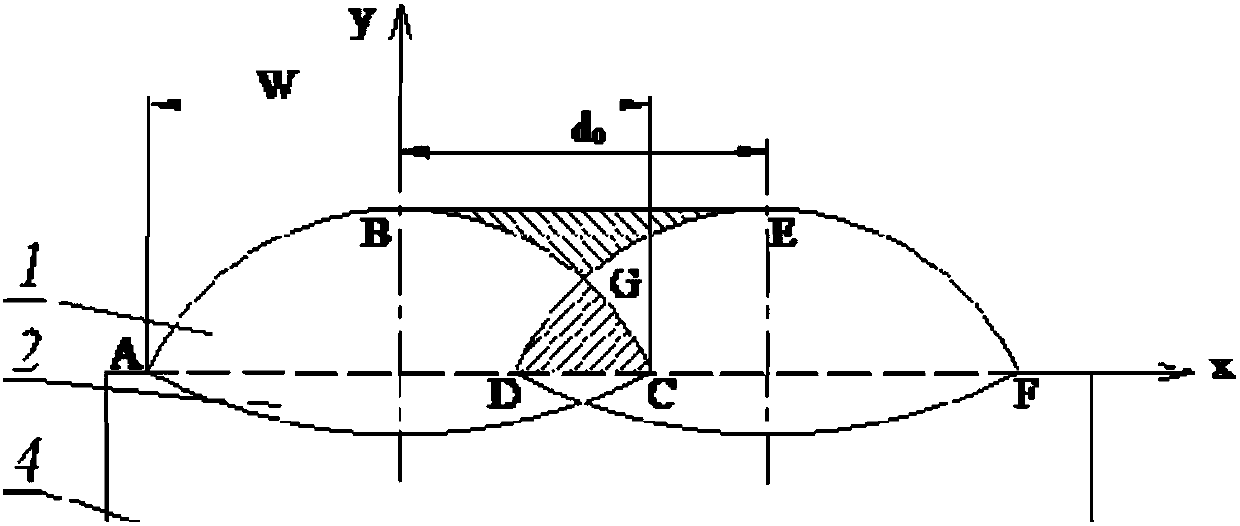

[0042] S1. Taking laser power, scanning speed, and powder feeding speed as the parameters to be optimized, an orthogonal experiment is designed according to the Taguchi method. After a single-pass cladding experiment is performed on a plane, the obtained melting width, melting height, and dilution rate are used as the response target and The analysis of variance is carried out to obtain the degree of influence of the three parameters to be optimized on the three response targets.

[0043] Further, step S1 includes the following sub-steps:

[0044] S11. Select the main influencing factors in the single-pass cladding experiment (including laser power, scanning speed, powder feeding speed, etc.) as the parameters to be optimized, select 3 to 5 levels according to the actual situation, and obtain the orthog...

Embodiment 2

[0112] In this example, on the basis of Example 1, the specific selected cladding powder and laser cladding equipment will be operated to find out the application of the cladding powder to the laser cladding equipment for laser single-pass cladding experiment. optimal parameters when . The following will mainly describe the selected parameters and the obtained data, etc., the specific steps refer to Example 1, which will not be repeated here, as follows:

[0113] The selected cladding powder is iron-based self-fluxing powder Fe313, the selected laser cladding equipment is a laser cladding head and a 6-axis KUKA robot integrated system, and the laser model is IPG-YLR500.

[0114] In step S1: select 5 levels, the 5 levels selected for laser power are 250W, 300W, 350W, 400W and 450W respectively, and the 5 levels selected for scanning speed are 3mm / s, 4mm / s, 5mm / s, 6mm / s, 7mm / s, the 5 levels selected for powder feeding speed are 0.5r / min, 0.65r / min, 0.8r / min, 0.95r / min, 1.1r / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com