Optimization method for metal 3D printing technology parameters

A technology of process parameter optimization and 3D printing, which is applied in the field of 3D printing, can solve the problems of many experiments, low experiment efficiency, labor and material resources, and achieve the effect of reducing costs and reducing the number of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

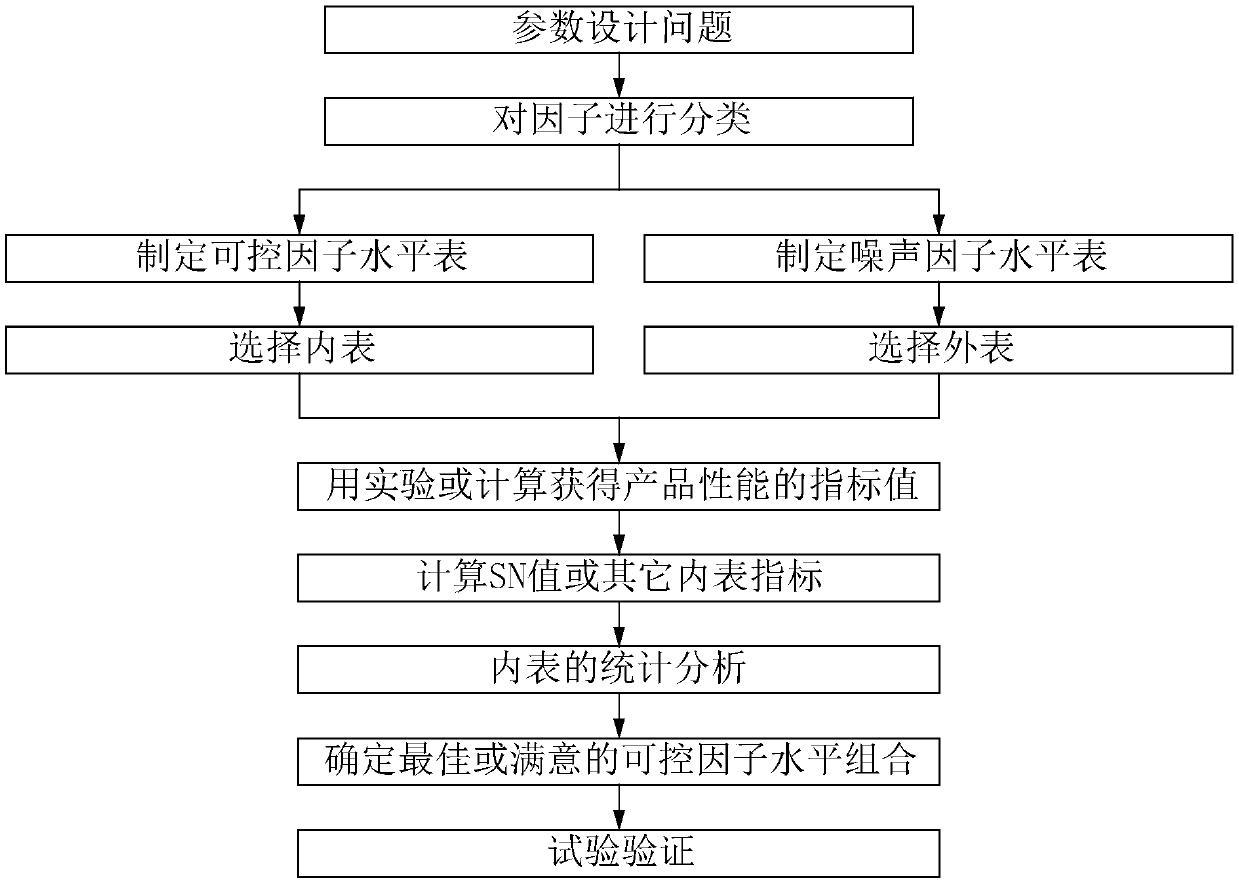

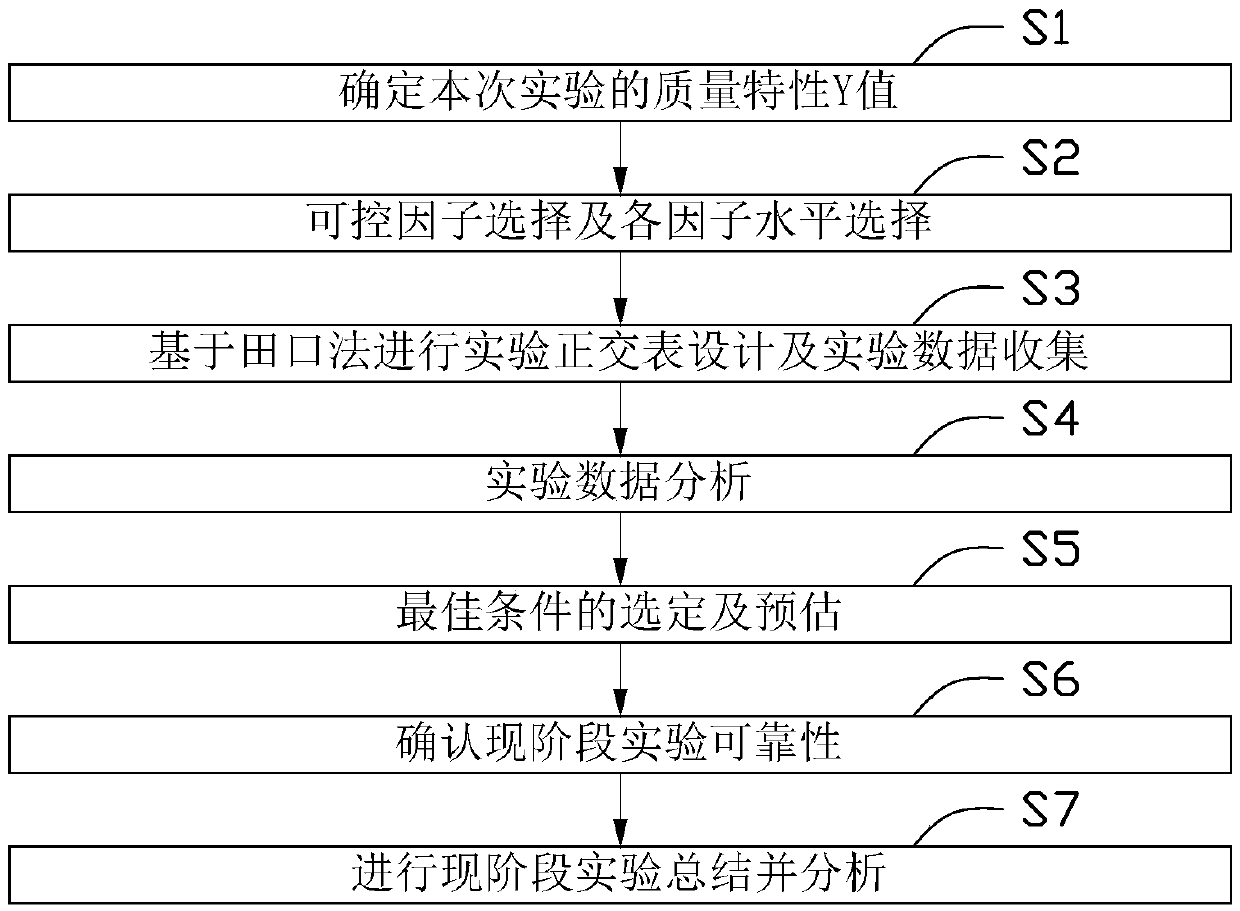

[0042] The metal 3D printing process parameter optimization method provided by the present invention is based on the Taguchi method, and the experimental design of the Taguchi method is as follows: figure 1 shown. The metal 3D printing process parameter optimization method of the present invention includes:

[0043] S1 determines the quality characteristic Y value of this experiment;

[0044] S2 Selection of controllable factors and level selection of each factor;

[0045] S3 conducts experimental orthogonal table design and experimental data collection based on Taguchi method;

[0046] S4 experimental data analysis;

[0047] Selection and estimation of the best conditions for S5;

[0048] S6 confirms the reliability of the current experiment;

[0049] S7 summarizes and analyzes the experiments at this stage.

[0050] Preferably, in S1, the quality characteristic Y value of this experiment is the specific density of parts.

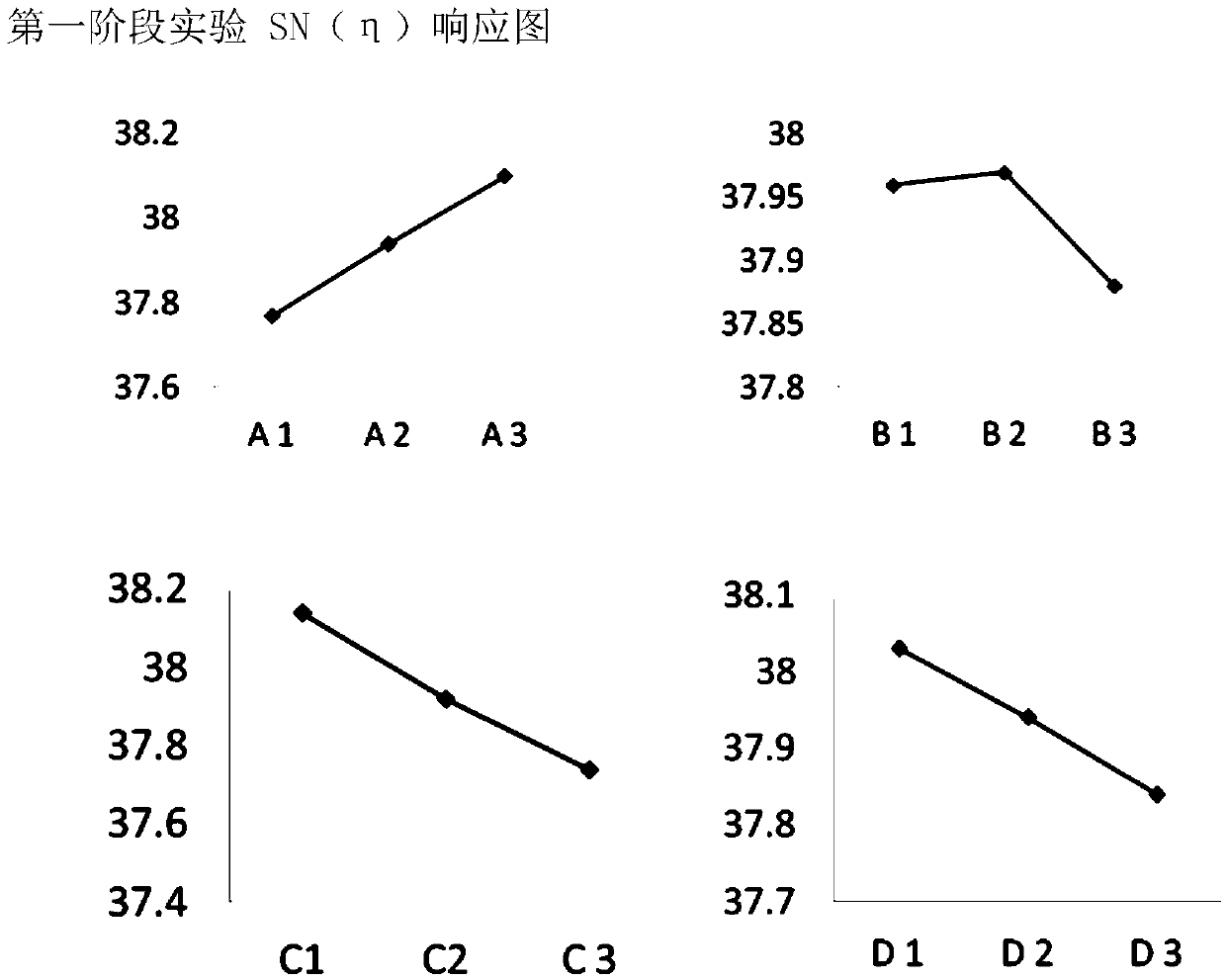

[0051] The factors affecting the forming effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com