Fractional-slot SPMSM magnetic pole structure optimization design method for reducing unbalanced magnetic pull

A technology of magnetic pole structure and optimized design, applied in the shape/pattern/structure of magnetic circuit, synchronous motor with stationary armature and rotating magnet, magnetic circuit, etc. Time and other issues, to achieve the effect of reducing unbalanced magnetic pull and torque fluctuation, improving stability, and improving the ability to resist error interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Taking a 48p / 54s motor as an example below, the embodiment of the present invention will be described in detail. The parameters of the motor are shown in Table 1.

[0041] Table 1 Fraction slot SPMSM parameters

[0042]

[0043]

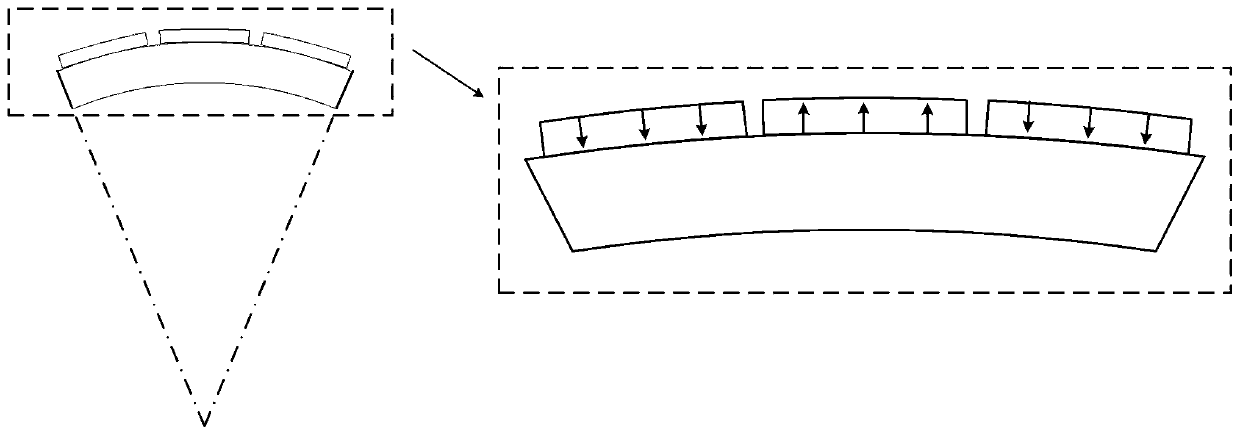

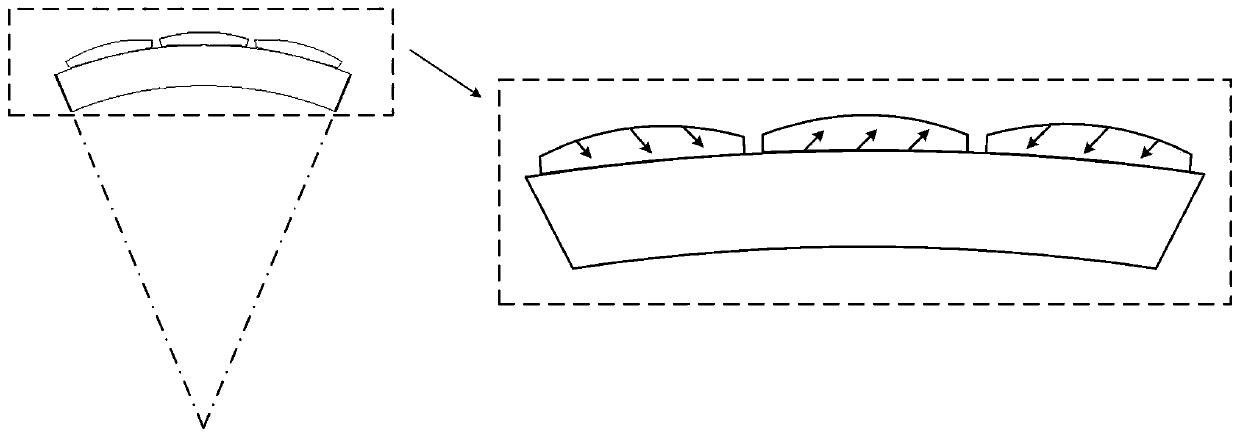

[0044] (1) The initial magnetic poles of the fractional slot SPMSM adopt the equal-thickness magnetic pole structure with 90° parallel magnetization, such as figure 1 shown;

[0045] (2) put forward if figure 2 The improvement scheme of the motor magnetic pole shown, that is, the unequal thick magnetic pole structure with the magnetization direction changed;

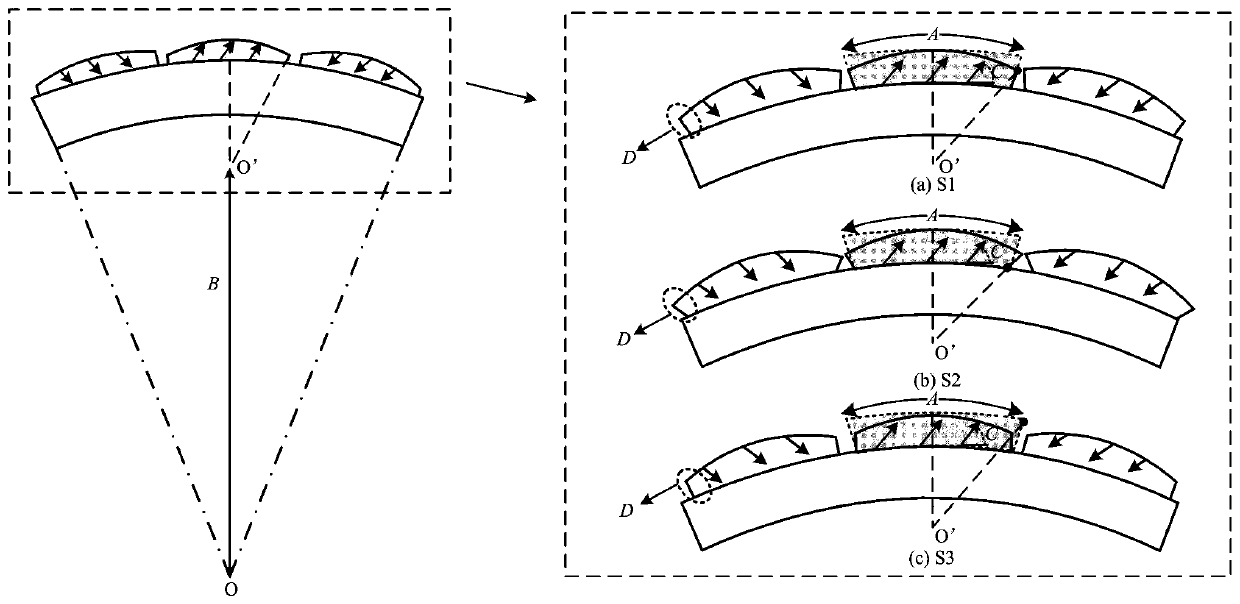

[0046] (3) To reduce the torque fluctuation and unbalanced magnetic pull of the motor as the optimization goal, the Taguchi method is selected as the method for the optimal design of the fractional slot SPMSM magnetic pole structure, and the selection of optimization variables is as follows image 3 Shown:

[0047] A-the polar arc coefficient of the original equal-thickness ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com