Control method for realizing efficient idle operation in laser pipe cutter

A control method and technology of pipe cutting machine, applied in the direction of digital control, laser welding equipment, electrical program control, etc., can solve the problems of processing efficiency discount, collision, long processing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

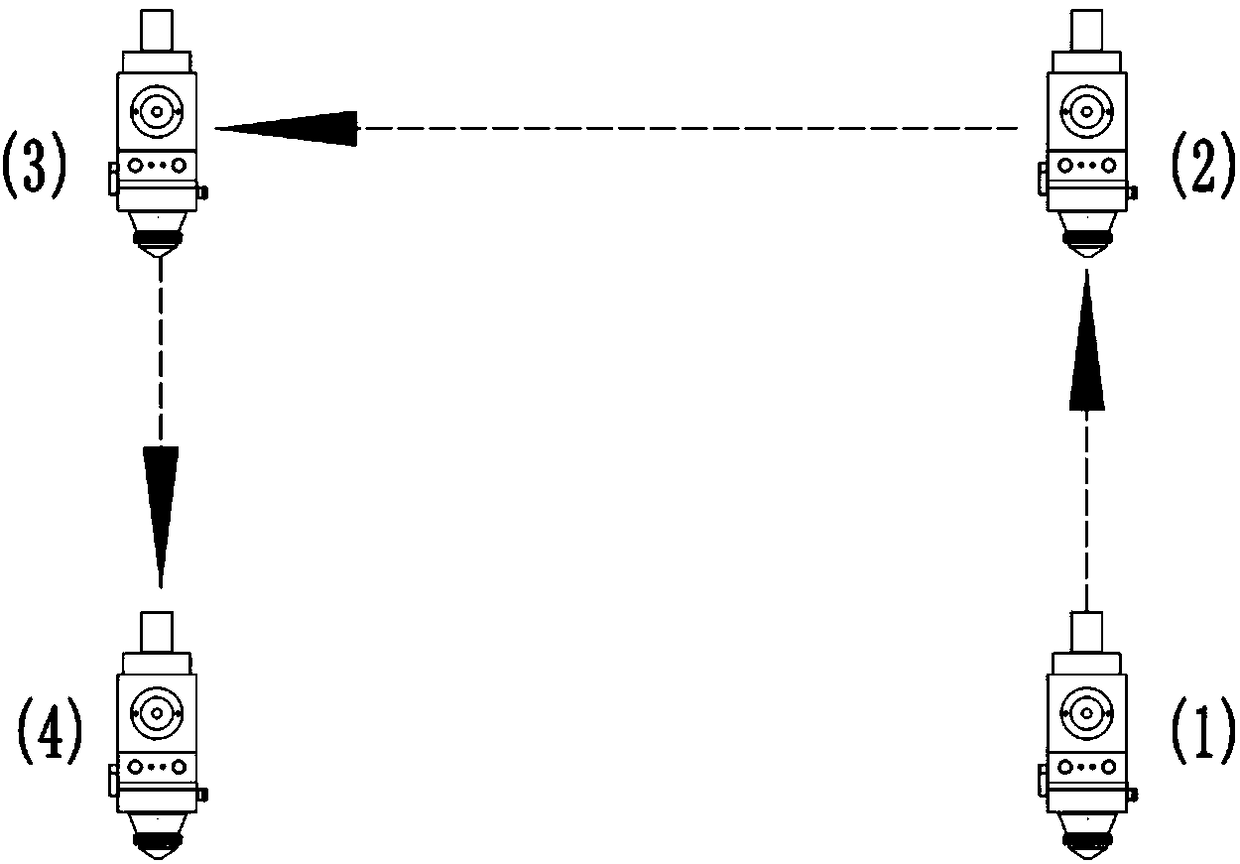

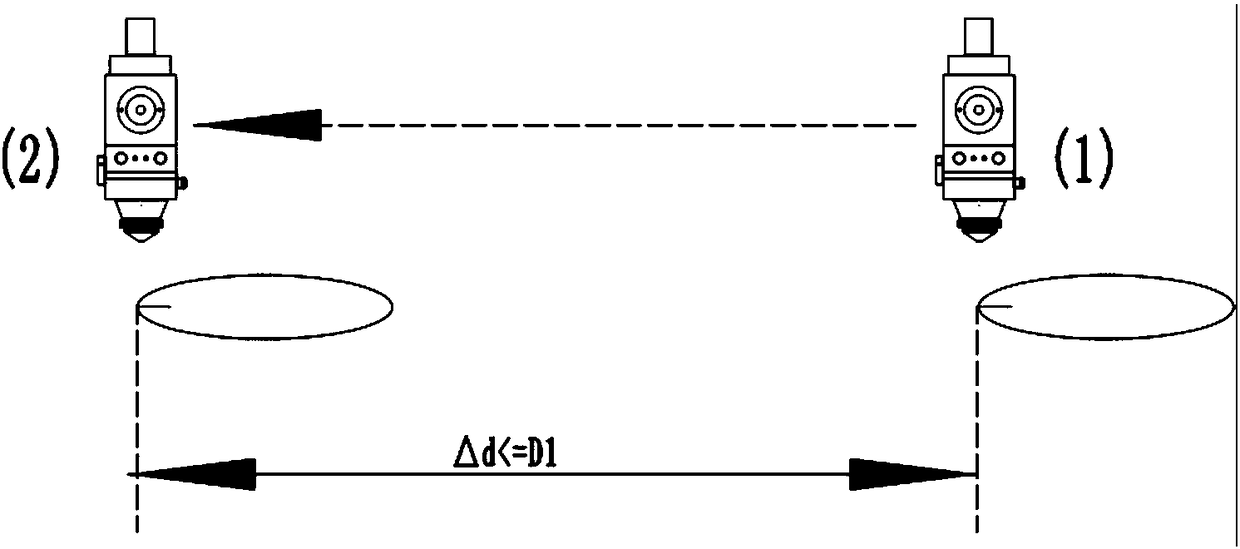

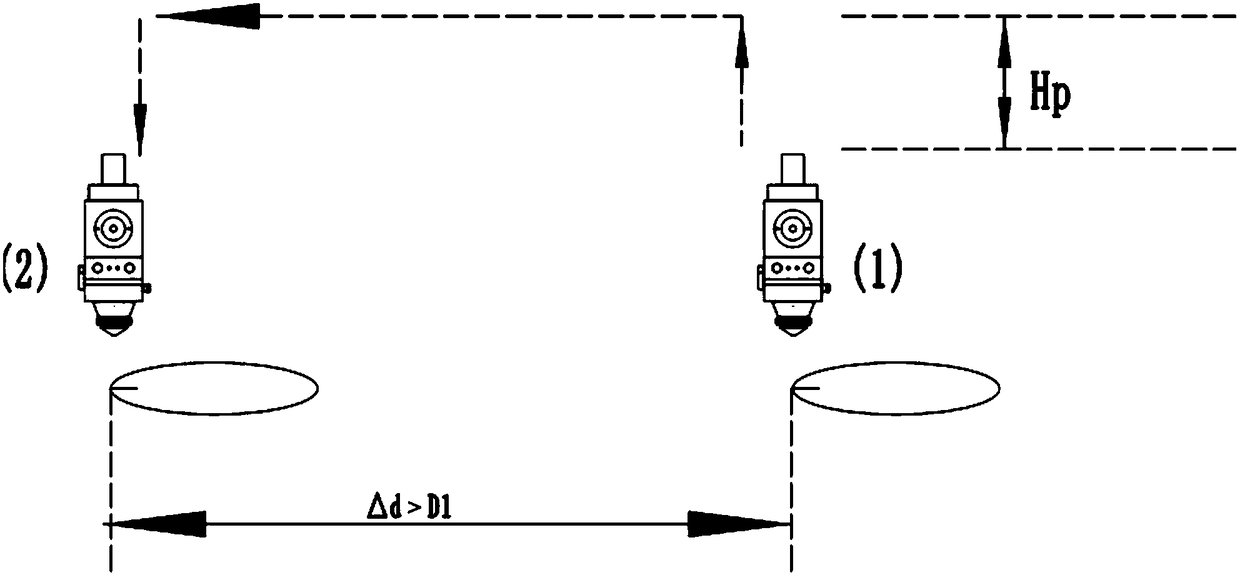

[0035] The flow chart of a control method for realizing high-efficiency dry operation in a laser pipe cutting machine is as follows Figure 7 As shown, the pipe nesting software outputs four different control codes according to the cutting contour, and the CNC system controls the cutting head to perform four different ways of empty movement. Before the air movement starts, the parameters that need to be set include the generalized diameter TD of the pipe, that is, the minimum enclosing circle diameter of the pipe section, the Z-axis air-moving safety offset height Hs, the Z-axis gun safety offset height Ha, and the translation safety offset height Hp, the Z-axis height Ht on the surface of the pipe, the maximum distance of translation D1, the maximum distance of frog jump D2, the direction of pipe rotation is the A direction, where the zero point coordinate of the Z-axis is Z0, that is, the chuck rotation center is the zero point of the Z-axis; including the following step:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com