A dispenser structure for preparing multilayer cpp films

A dispenser and film technology, which is applied in the field of dispenser structure of multi-layer CPP film, can solve problems such as uneven distribution technology, difficulty in uniform distribution, and difficulty in co-extrusion of multi-layer CPP film layers, so as to achieve uniform distribution of formula, The effect of fluid stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

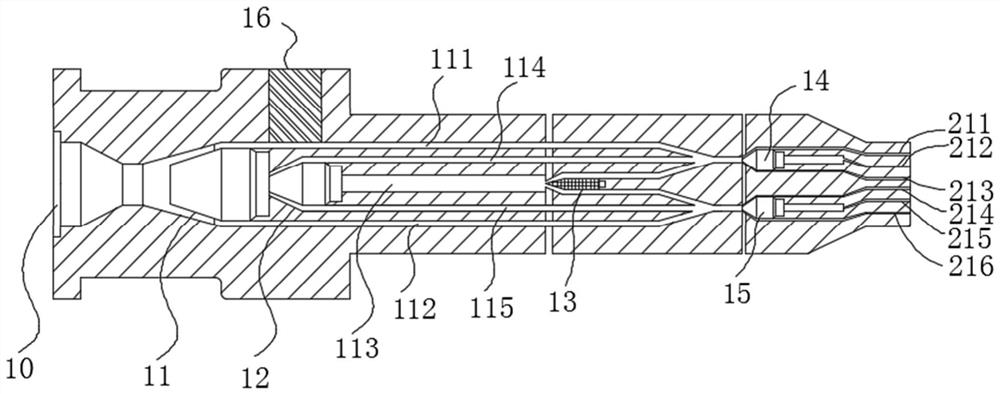

[0019] like figure 1 As shown, it is a schematic diagram of a distributor structure for preparing multilayer CPP film, which includes: raw material inlet (10), splitter cone (11, 12, 14, 15), splitter pipe (111, 112, 114, 115), central tube (113), flow limiting cone (13), characterized in that: two splitter cones (11, 12) are sequentially and concentrically set on the central tube (113), wherein the first splitter cone (11) One end of the first splitter cone (11) is connected to the raw material inlet (10), and the other section of the first splitter cone (11) is concentrically nested at one end of the second splitter cone (12). Each splitter cone (11, 12, 14, 15) , the fluid will be divided into two strands, and will be transmitted along the axial direction through the splitter tubes (111, 112, 114, 115). The fluid of the flow cone (13) and the front shunt pipes (111, 114) will merge into a stream of fluid I, and the fluid passing through the flow restrictor cone (13) will m...

specific Embodiment example 2

[0021] A distributor for preparing multilayer CPP films, comprising: raw material inlets (10), splitter cones (11, 12, 14, 15), splitter pipes (111, 112, 114, 115), central tubes (113 ), restrictor cone (13), characterized in that: two diverter cones (11, 12) are concentrically set on the central tube (113) successively, wherein one end of the first diverter cone (11) is connected to the raw material inlet (10 ), the other section of the first splitter cone (11) is concentrically nested at one end of the second splitter cone (12), and each time a splitter cone (11, 12, 14, 15) passes through, the fluid will be divided into 2 Strand, and through the distribution tube (111, 112, 114, 115) along the axial direction transmission, at the end of the center tube (113) set restrictor cone (13), and the flow through the restrictor cone (13) It will merge with the front shunt tubes (111, 114) into a stream of fluid I, and at the same time, the fluid passing through the restrictor cone (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com