Axial-flow type non-return valve

A check valve, axial flow technology, used in valve details, control valves, valve devices, etc., can solve problems such as damaged valve sealing performance, short valve service life, unstable pipeline pressure and caliber, and reduce work. The effect of volume, smooth operation and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

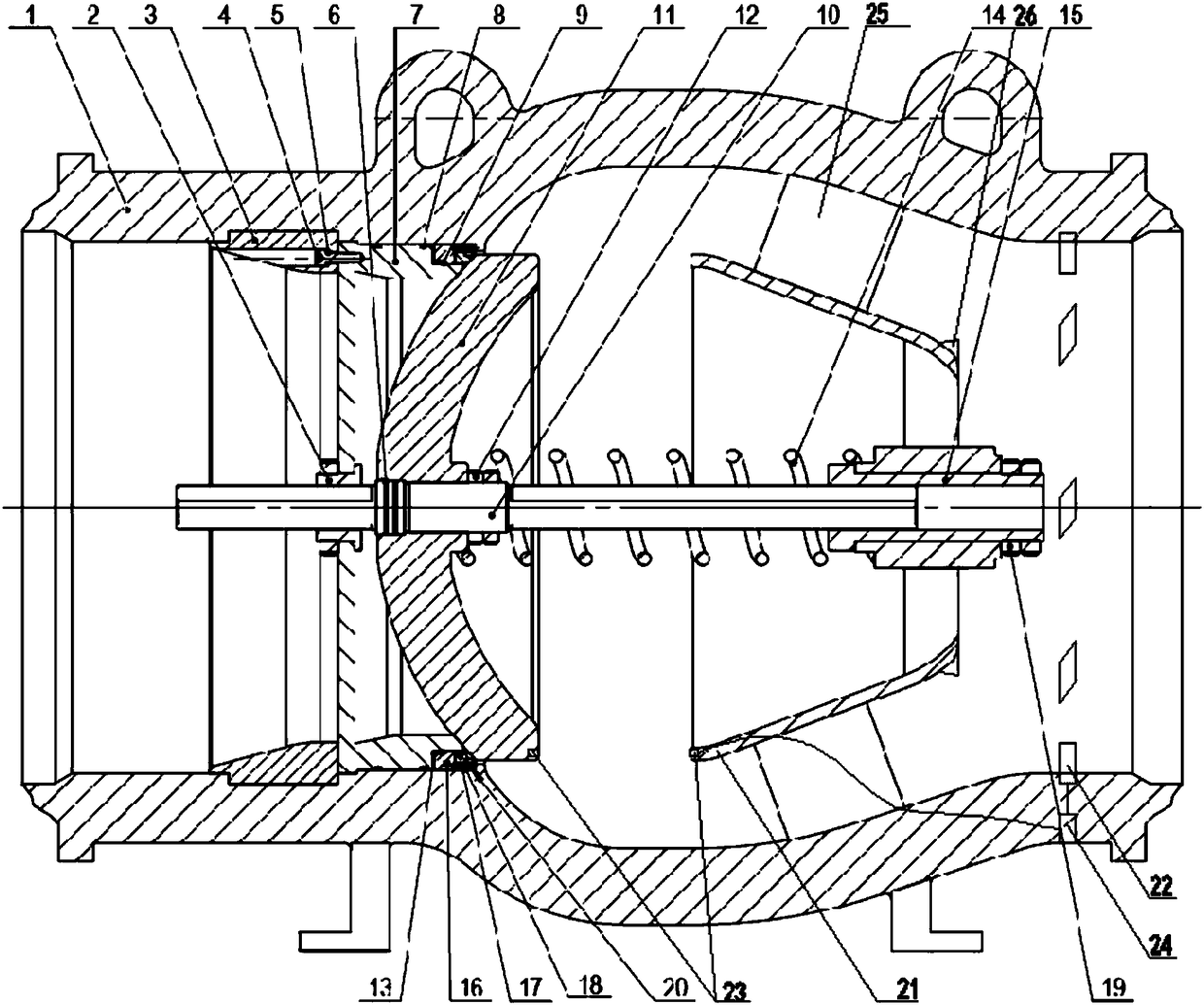

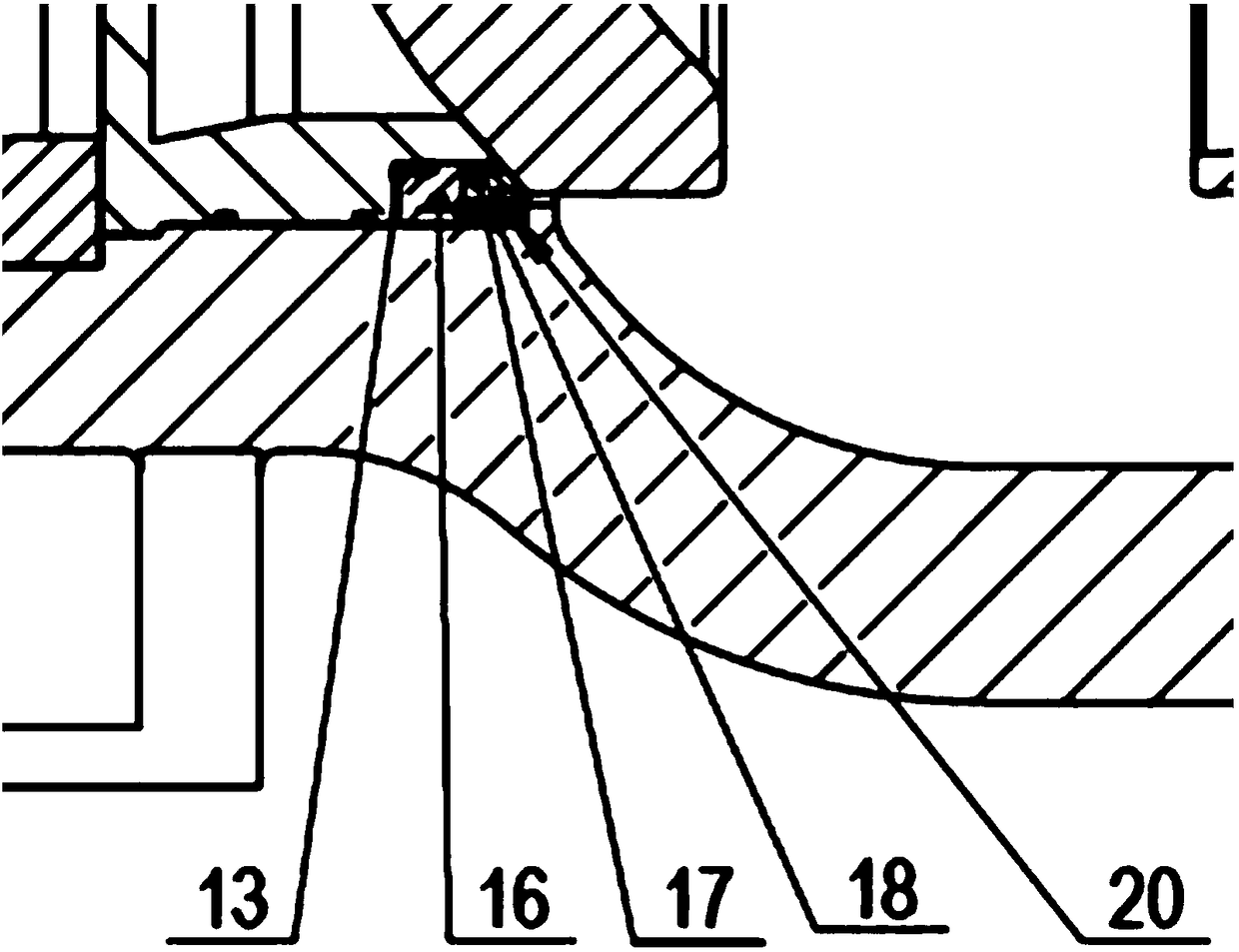

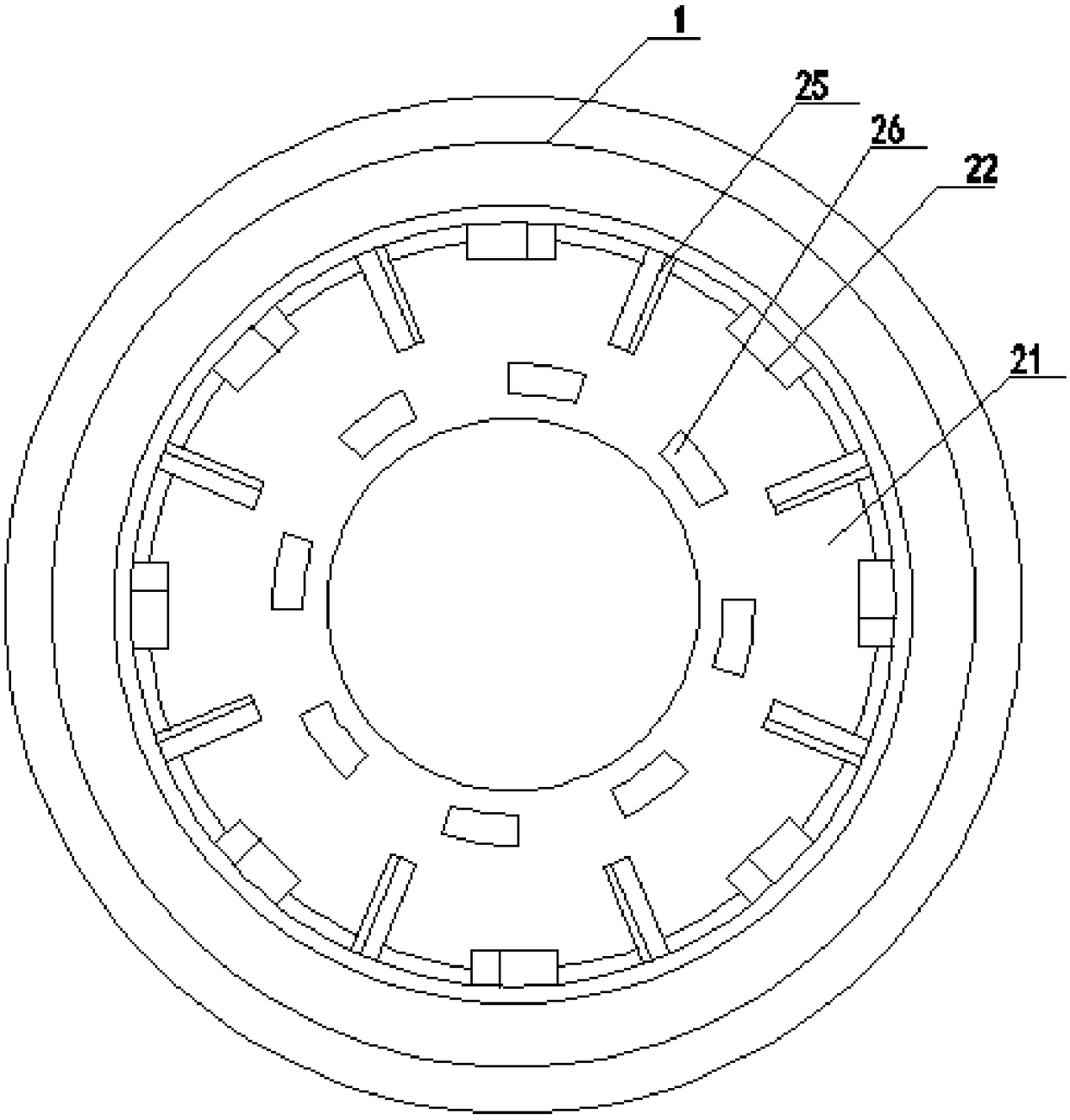

[0014] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0015] like figure 1 , 2 As shown, the axial flow check valve includes a valve body 1, a base 21 fixed in the valve body 1 through a support plate 25, a rear bushing 15 fixed on the base 21, and a rear end part at least partially penetrated The valve shaft 10 inside the rear bushing 15 and slidable relative to the rear bushing 15 , the valve flap 11 fixedly connected with the front end of the valve shaft 10 , fixed in the valve body 1 and Matching with the valve disc 11, the valve seat 7 which can seal the valve body 1 into two parts and the three-open ring 3 which is arranged in the valve body 1 and is fixedly connected with the valve seat 7, the valve shaft 10 The front end is slidably connected to the front bushing 2, the front bushing 2 is fixed on the valve seat 7, and a pressure for resetting the valve flap 11 and buffering is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com