A kind of pearlescent composition and its preparation method and application

A composition and pearlescent technology, which is applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of inability to show pearlescent luster, the product is not mild enough, allergy or infection, etc., and achieves excellent moisturizing effect and good pearlescent effect. Good gloss and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

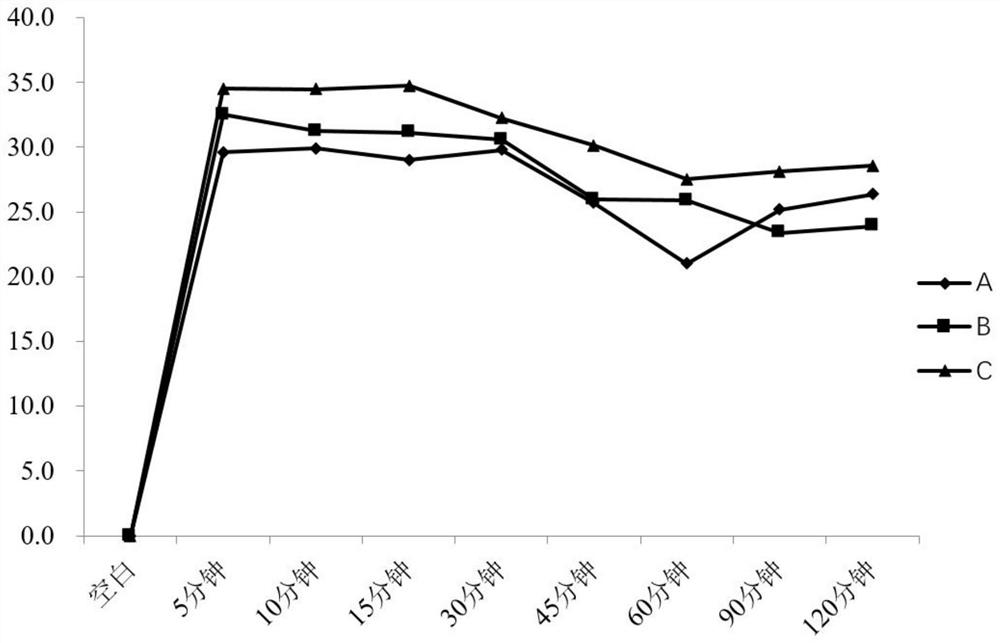

Embodiment 1

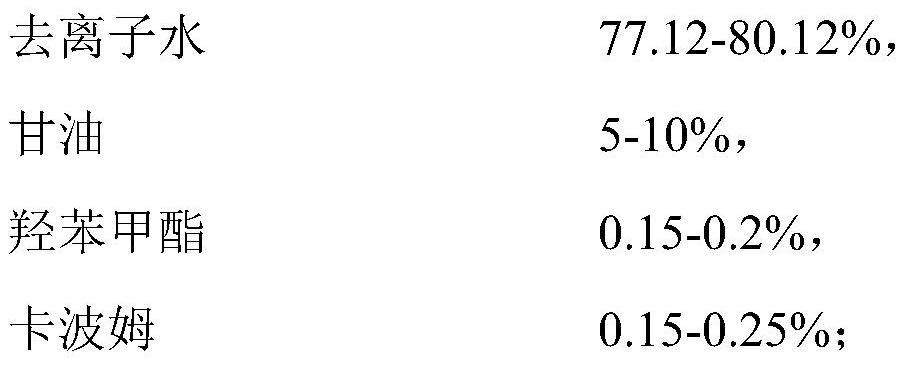

[0033] A kind of pearl luster composition, raw material total amount is 100 kilograms, comprises:

[0034] Phase A materials: 77.12 kg of deionized water, 8.23 kg of glycerin, 0.15 kg of methylparaben, and 0.15 kg of carbomer;

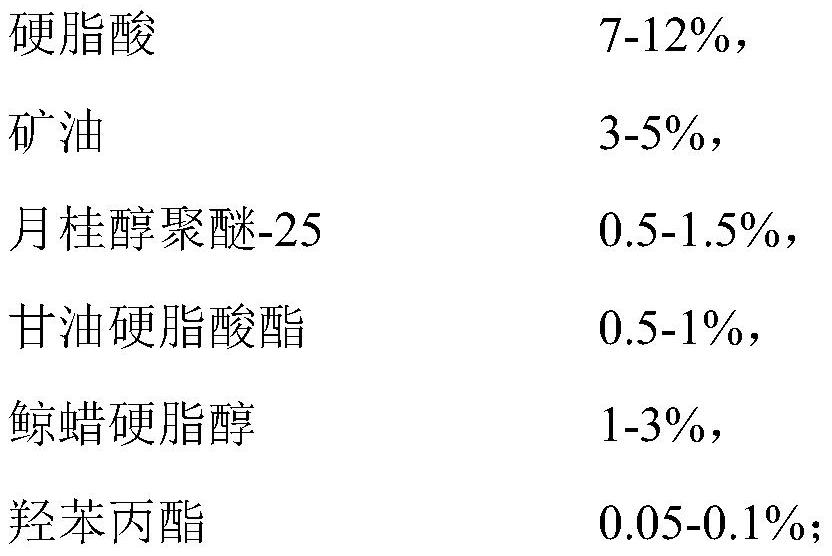

[0035] Phase B materials: 8.95 kg of stearic acid, 3 kg of mineral oil, 0.5 kg of laureth-25, 0.5 kg of glyceryl stearate, 1 kg of cetearyl alcohol, and 0.05 kg of propylparaben;

[0036] Phase C material: 0.05 kg of sodium hydroxide;

[0037] Phase D material: 0.3 kg of phenoxyethanol.

Embodiment 2

[0039] A kind of pearl luster composition, raw material total amount is 100 kilograms, comprises:

[0040] Phase A materials: 77.12 kg of deionized water, 8.23 kg of glycerin, 0.15 kg of methylparaben, and 0.15 kg of carbomer;

[0041] Phase B materials: 8.9 kg of stearic acid, 3 kg of mineral oil, 0.5 kg of laureth-25, 0.5 kg of glyceryl stearate, 1 kg of cetearyl alcohol, and 0.05 kg of propylparaben;

[0042] Phase C material: 0.1 kg of sodium hydroxide;

[0043] Phase D material: 0.3 kg of phenoxyethanol.

Embodiment 3

[0045] A kind of pearl luster composition, raw material total amount is 100 kilograms, comprises:

[0046] Phase A materials: 77.12 kg of deionized water, 8.23 kg of glycerin, 0.15 kg of methylparaben, and 0.15 kg of carbomer;

[0047] Phase B materials: 8.86 kg of stearic acid, 3 kg of mineral oil, 0.5 kg of laureth-25, 0.5 kg of glyceryl stearate, 1 kg of cetearyl alcohol, and 0.05 kg of propylparaben;

[0048] Phase C material: 0.14 kg of sodium hydroxide;

[0049] Phase D material: 0.3 kg of phenoxyethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com