Catalyst for catalytic oxidation of ozone, method for preparing same and method for using same to treat industrial wastewater

A technology of ozone catalytic oxidation and catalyst, which is applied in the direction of oxidized water/sewage treatment, physical/chemical process catalysts, chemical instruments and methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

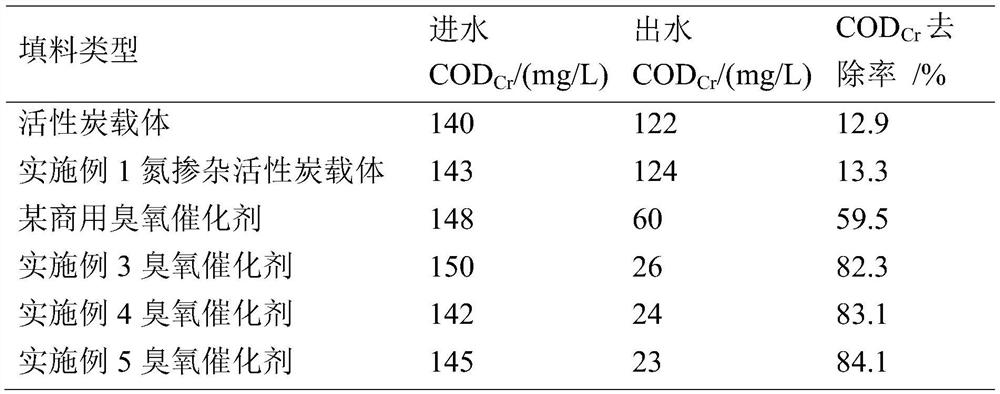

Examples

Embodiment 1

[0022] The preparation process of a doped activated carbon carrier with a nitrogen content of 3 wt% is as follows: add 500 mL of concentrated nitric acid to 500 g of activated carbon, heat at 70 °C for 4 h, filter, wash until neutral, and dry for later use. Take 400g of nitric acid-treated activated carbon, add 1000mL of water, and ultrasonically disperse it, then add an aqueous solution containing 100g of melamine to it, and keep stirring for 2h. The water was removed by heating, and the obtained solid mixture was heated to 400° C. under nitrogen, kept for 4 hours, and cooled to room temperature. According to the elemental analysis method, a nitrogen-doped activated carbon carrier with a mass fraction of nitrogen of 3% was obtained.

Embodiment 2

[0024] The preparation process of the doped activated carbon carrier with a nitrogen content of 5wt% is as follows: add 500mL concentrated nitric acid to 500g activated carbon, heat at 70°C for 4h, filter, wash until neutral, and dry for later use. Take 400g of nitric acid-treated activated carbon, add 1000mL of water, and ultrasonically disperse, then add an aqueous solution containing 150g of melamine, and keep stirring for 2h. The water was removed by heating, and the obtained solid mixture was heated to 400° C. under nitrogen, kept for 4 hours, cooled to room temperature, and detected by elemental analysis to obtain a nitrogen-doped activated carbon carrier with a mass fraction of nitrogen of 5%.

Embodiment 3

[0026] The nitrogen-doped activated carbon with a nitrogen content of 3% prepared in Example 1 was used as a carrier, Fe 2 o 3 , MnO 2 and CuO as active components, Ru 2 o 3 The preparation process of the catalyst as the auxiliary agent is as follows: the respective configuration concentrations are 0.5mol / L Fe(NO 3 ) 3 , Mn(NO 3 ) 4 , Cu(NO 3 ) 2 Aqueous solution, RuCl 3 Aqueous solution, take the prepared 0.5mol / L Fe(NO 3 ) 3 , Mn(NO 3 ) 4 , Cu(NO 3 ) 2 、RuCl 31300mL, 213ml, 373ml, and 175ml of the aqueous solution are mixed evenly, that is, the mixed solution contains 0.65mol, 0.1065mol, 0.1865mol and 0.0875mol of Fe ions, Mn ions, Cu ions and Ru ions respectively; take 274g of activated carbon with a nitrogen content of 3wt% The carrier was dispersed in 100g of water, and then the well-mixed four metal salt solutions were added dropwise to the activated carbon slurry, stirred at 70°C for 1 hour, and then an alkaline solution was added to adjust the pH value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com