Method and device for testing heating sintering characteristics of solid-state continuous casting covering slag

A continuous casting mold slag, solid-state technology, applied in the measurement device, the preparation of test samples, and the use of stable tension/pressure to test the strength of materials, etc. Sintering start temperature, sintering rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

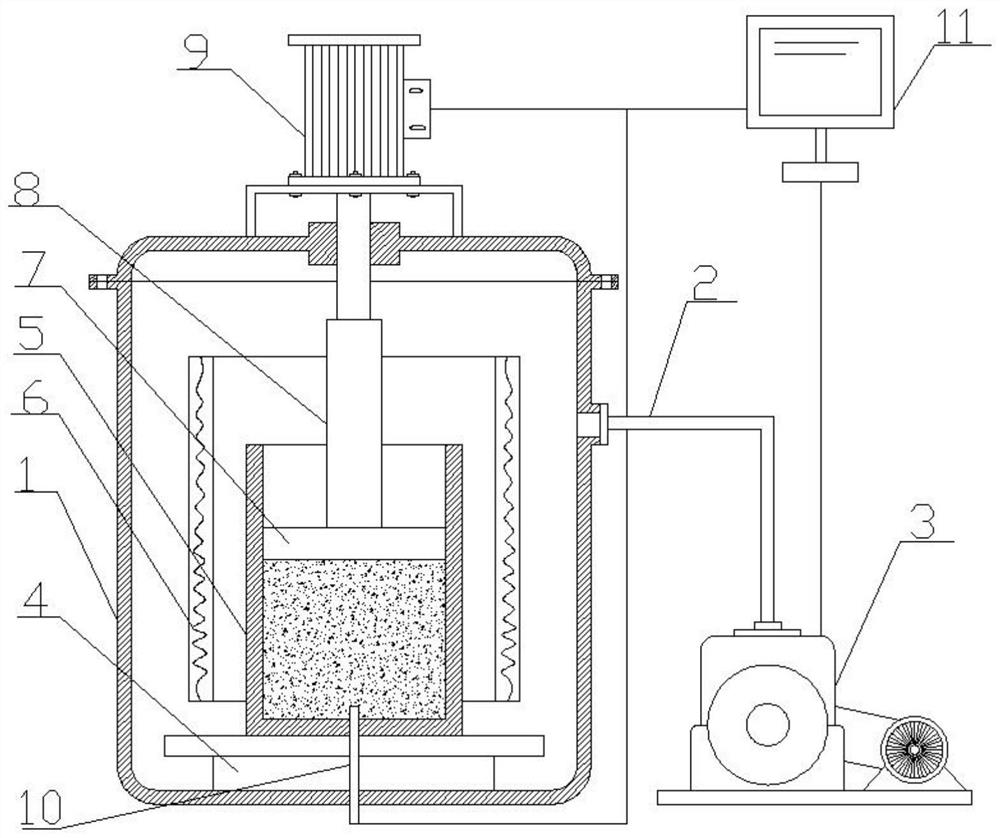

Image

Examples

Embodiment 1

[0025] Embodiment 1: A method for testing the heating and sintering characteristics of solid continuous casting mold flux is to detect the volumetric strain data of solid continuous casting mold flux under the condition of rising temperature in real time under the condition of constant or regular change of compressive stress, and analyze the temperature -Volume strain curve, to obtain the sintering characteristics of solid continuous casting mold flux at elevated temperature.

[0026] The real-time detection is carried out within the temperature range of 100-1200°C.

[0027] During the real-time detection, the range of compressive stress is 0.2MPa.

[0028] During the real-time detection, the solid continuous casting mold flux is in a vacuum environment.

[0029] During the real-time detection, the heating rate range is 25° C. / min.

[0030] Table 1 lists the data of the different carbon content of the same type of mold powder, and the rest are impurities. In the three formul...

Embodiment 2

[0035] Embodiment 2: A method for testing the heating and sintering characteristics of solid continuous casting mold flux is to detect the volumetric strain data of solid continuous casting mold flux under the condition of rising temperature in real time under the condition of constant or regular change of compressive stress, and analyze the temperature -Volume strain curve, to obtain the sintering characteristics of solid continuous casting mold flux at elevated temperature.

[0036] The real-time detection is carried out within the temperature range of 100-1200°C.

[0037] During the real-time detection, the range of compressive stress is 0.1MPa.

[0038] During the real-time detection, the solid continuous casting mold flux is in a vacuum or an inert gas environment.

[0039] During the real-time detection, the heating rate range is 3° C. / min.

Embodiment 3

[0040] Embodiment 3: A method for testing the heating and sintering characteristics of solid continuous casting mold flux is to detect the volume strain data of solid continuous casting mold flux in real time under the condition of constant or regular change of compressive stress, and analyze the temperature -Volume strain curve, to obtain the sintering characteristics of solid continuous casting mold flux at elevated temperature.

[0041] The real-time detection is carried out within the temperature range of 100-1200°C.

[0042] During the real-time detection, the range of compressive stress is 2MPa.

[0043] During the real-time detection, the solid continuous casting mold flux is in a vacuum or an inert gas environment.

[0044] During the real-time detection, the heating rate range is 100° C. / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com