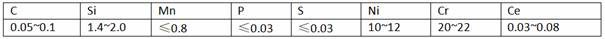

Pre-melting type crystallizer casting powder for rare earth stainless steel and preparation method of pre-melting type crystallizer casting powder

A technology of mold mold slag and stainless steel, applied in the field of metallurgy, to achieve good heat insulation effect, light stack specific gravity, and reduce heat transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

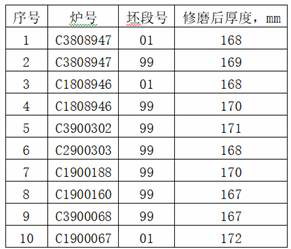

Examples

Embodiment 1

[0023] The present embodiment provides a pre-melting mold mold powder for rare earth stainless steel. According to the characteristics of rare earth stainless steel continuous casting, the pre-melting mold mold mold powder has (1) relatively high oxidation resistance; (2) relatively good The ability to dissolve and absorb rare earth inclusions, lower the viscosity of mold slag; (3) lower solidification temperature and crystallization rate, thereby improving the lubrication of mold slag; (4) appropriate melting speed can control the thickness of the slag layer, Thin slag layer will shorten the reaction time between slag and rare earth; (5) high basicity can improve the ability and speed of mold slag to dissolve, absorb inclusions, and control heat transfer. 2 It reacts with rare earth to increase the basicity of slag, and the basicity of mold slag is not easy to be too high. The appropriate basicity should be 0.95 to 1.05; (7) Select the appropriate flux, carbonaceous material ...

Embodiment 2

[0028] The present embodiment provides a pre-melting mold mold powder for rare earth stainless steel, which comprises 48.6 parts of pre-melted calcium silicate with a particle size of 200 mesh or more, 8.1 parts of blast furnace water slag, 5.6 parts of albite, 2.8 parts of quartz powder, Lithium carbonate 0.7 parts, soda ash 10.4 parts, sodium fluoride 2.3 parts, fluorite 12.3 parts, borax 2.0 parts, strontium carbonate 2.0 parts, sodium silicate 1.0 parts, metal silicon 1.5 parts, calcined alpha alumina 0.9 parts, mixed carbon 1.8 parts , plus binder and water, through batching, pulping, spray granulation, screening, cooling, testing, and packaging, the pre-melting mold mold powder for rare earth stainless steel is obtained.

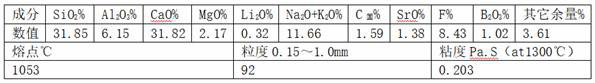

[0029] Table 3 Physical and chemical indicators of embodiment 2

[0030] .

Embodiment 3

[0032] The present embodiment provides a pre-melted mold slag for rare earth stainless steel, comprising 50.8 parts of pre-melted calcium silicate with a particle size of 200 mesh or more, 6.8 parts of blast furnace water slag, 6.7 parts of albite, 2.5 parts of quartz powder, 1.0 parts of lithium carbonate, 10.0 parts of soda ash, 3.0 parts of sodium fluoride, 11.5 parts of fluorite, 1.5 parts of borax, 1.5 parts of strontium carbonate, 0.9 parts of sodium silicate, 1.0 parts of metallic silicon, 1.0 parts of calcined alpha alumina, 1.8 parts of mixed carbon , plus binder and water, through batching, pulping, spray granulation, screening, cooling, testing, and packaging, the pre-melting mold mold powder for rare earth stainless steel is obtained.

[0033] Table 4 Physical and chemical indicators of embodiment 3

[0034] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com