Adhesive for magnesian wall and preparation method of adhesive

A wall and glue technology, applied in the field of building materials, to achieve the effect of not easy to fall off and break, enhance adhesion, and good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0036] In this preparation example, the magnesium wall adhesive uses the following raw material components in parts by weight: magnesium oxide: 100 parts, magnesium sulfate solution: 83 parts, phosphoric acid: 2 parts, sodium phosphate: 2 parts, 108 glue: 10 parts , Rubber powder: 10 parts, concrete interface agent: 5 parts, sawdust: 3 parts, fly ash: 8 parts, glass fiber: 1 part, water: 10 parts.

[0037] During preparation, magnesium sulfate heptahydrate is dissolved in water to prepare a magnesium sulfate solution with a Baume degree of 29, and then the magnesium sulfate solution is added into a reaction kettle. Then, add magnesium oxide into the reaction kettle and stir evenly, then add phosphoric acid, sodium phosphate, 108 glue, rubber powder, and concrete interface agent into the reaction kettle at one time, and stir at 650rpm for 25min to make the components in the reaction kettle fully Dissolve and mix. Next, add straw or sawdust, fly ash, glass fiber, and water into...

preparation example 2

[0039] In this preparation example, the magnesium wall adhesive uses the following raw material components in parts by weight: magnesium oxide: 200 parts, magnesium sulfate solution: 170 parts, phosphoric acid: 3 parts, sodium phosphate: 3 parts, 108 glue: 20 parts , Rubber powder: 20 parts, concrete interface agent: 8 parts, sawdust: 8 parts, fly ash: 16 parts, glass fiber: 2 parts, water: 25 parts.

[0040] During preparation, magnesium sulfate heptahydrate is dissolved in water to prepare a magnesium sulfate solution with a Baume degree of 30, and then the solution is added to the reaction kettle. Then, add magnesium oxide into the reaction kettle and stir evenly, then add phosphoric acid, sodium phosphate, 108 glue, rubber powder, and concrete interface agent into the reaction kettle at one time, and stir at 700rpm for 25min to make the components in the reaction kettle fully Dissolve and mix. Next, add straw or sawdust, fly ash, glass fiber, and water into the reaction ket...

preparation example 3

[0042] In this preparation example, the magnesium wall adhesive uses the following raw material components in parts by weight: magnesium oxide: 200 parts, magnesium sulfate solution: 170 parts, phosphoric acid: 3 parts, sodium phosphate: 3 parts, 108 glue: 15 parts , rubber powder: 15 parts, concrete interface agent: 8 parts, straw: 8 parts, fly ash: 16 parts, glass fiber: 2 parts, water: 20 parts.

[0043] During preparation, magnesium sulfate heptahydrate is dissolved in water to prepare a magnesium sulfate solution with a Baume degree of 30, and then the magnesium sulfate solution is added into a reaction kettle. Then, add magnesium oxide into the reaction kettle and stir evenly, then add phosphoric acid, sodium phosphate, 108 glue, rubber powder, and concrete interface agent into the reaction kettle at one time, and stir at 750rpm for 25min to make the components in the reaction kettle fully Dissolve and mix. Next, add straw or sawdust, fly ash, glass fiber, and water int...

PUM

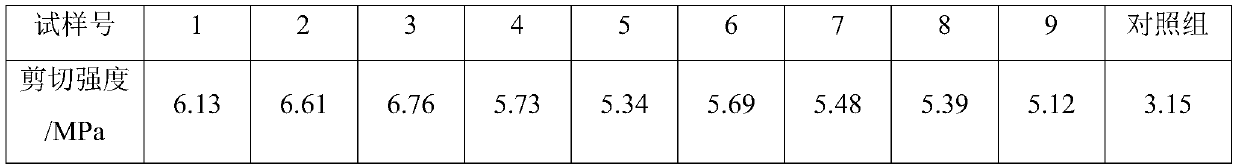

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com