Rack base assembly of end cover welding equipment

A technology for welding equipment and frame bases, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the difficulty of fixed-point rotation of moment gyroscopes, the complex structure of frame base components, and cannot be well controlled and Adjust the torque gyro rotation angle and other problems to achieve the effect of simple structure, reasonable design and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

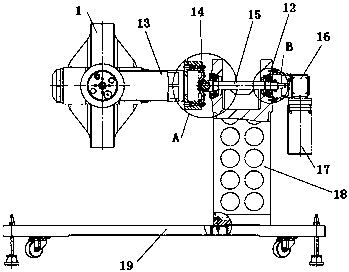

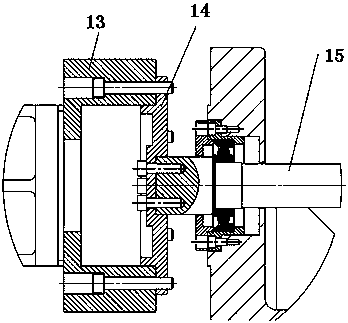

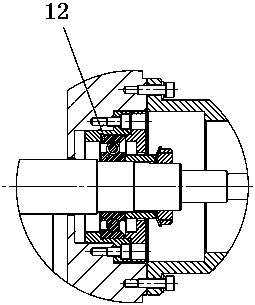

[0018] Depend on Figure 1-7 It can be seen that a frame seat assembly of an end cover welding equipment includes a turntable assembly 13, a transition plate 14, an output shaft 15, a worm gear reducer 16, a base frame 18 and a flat trolley 19, and the rear end of the turntable assembly 13 A transition plate 14 is provided, and the transition plate 14 is installed on one end of the output shaft 15 with screws, and the other end of the output shaft 15 is connected with a worm gear reducer 16, and the worm gear reducer 16 is connected with a stepping motor 17, wherein the The output shaft 15 is installed on the base frame 18 through a pair of angular joint ball bearings 12, which ensures the rotation accuracy and axial positioning accuracy of the output shaft 15. The base frame 18 is fixed on the flat trolley 19.

[0019] The turntable assembly 13 includes a moment gyro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com