Automatic printing and painting device

An automatic and automatic feeding technology, which is applied in the direction of decorative art and the process for producing decorative surface effects, etc., can solve the problems of increasing the initial production investment cost, not being able to print and coat toys, and occupying production space, so as to improve the printing and coating process. Efficiency, convenient printing and coating process, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

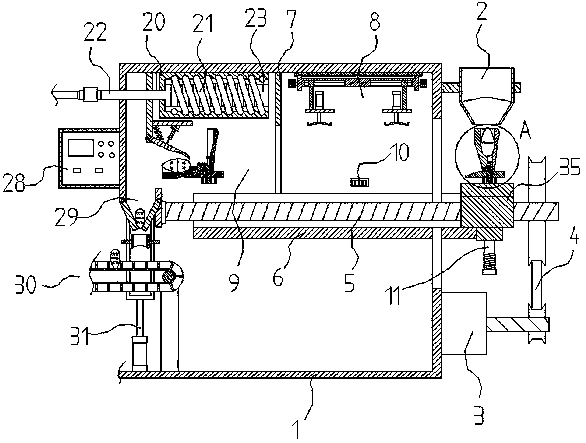

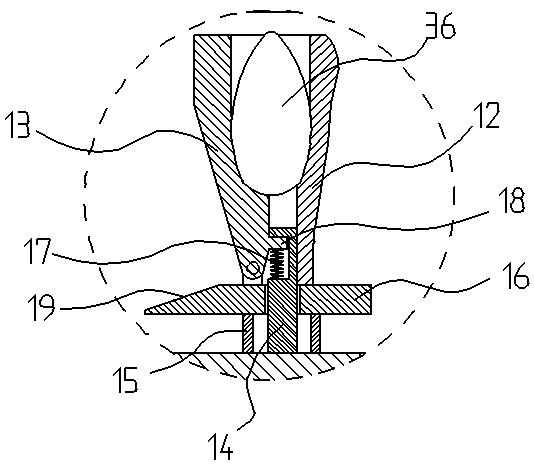

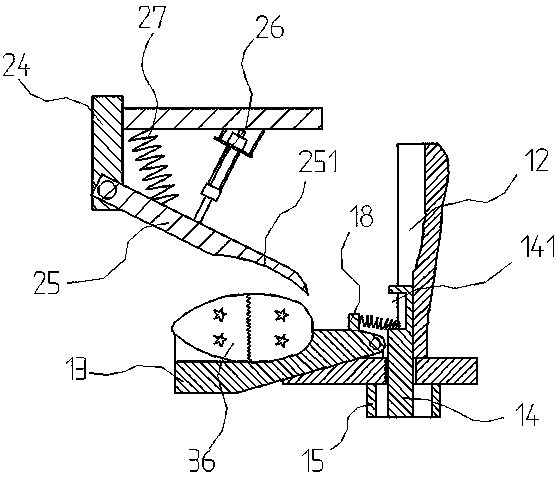

[0030] like Figure 1-Figure 5 As shown, the specific structure of the present invention is: it includes a frame 1 and an automatic feeding mechanism 2, a pad printing mechanism and a drying mechanism arranged on the frame 1; it is characterized in that: it is installed on the frame 1 There is a base 6, the base 6 is provided with a screw rod 5, the screw rod 5 is threadedly connected with a slide plate 35 that moves laterally on the base 6, and the screw rod 5 is connected with the feeding motor 3 by a driving belt 4; the slide plate 35 The egg 36 transfer assembly and the discharge cylinder 11 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com