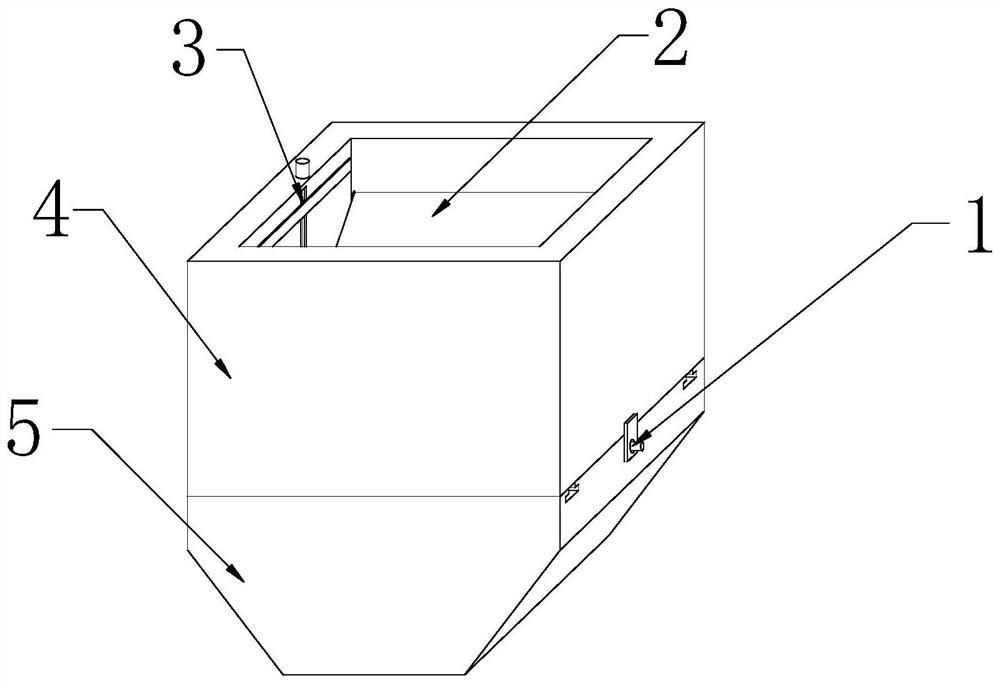

A kind of machine head coal leakage hopper for mining

A funnel and machine head technology, which is applied to conveyors, packaging, loading/unloading, etc., can solve the problems of increasing the difficulty of installation by operators, the lack of protective devices for the hopper of the machine head, and the difficulty of cleaning for operators, and achieves a novel structure. , good protection, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

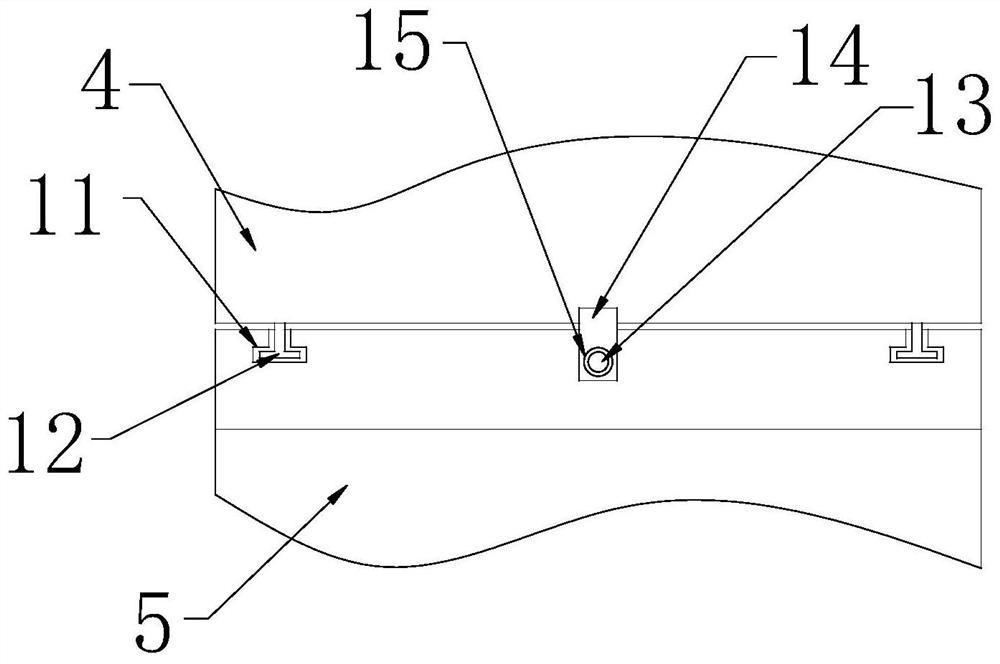

[0026] Specific implementation: when in use, the operator inserts the T-shaped slider 11 on the upper funnel 4 into the T-shaped slot 12, and pushes the upper funnel 4, and then the upper funnel 4 drives the T-shaped slider 11 to move in the T-shaped slot 12 , then the upper funnel 4 moves on the lower funnel 5, the upper funnel 4 moves to drive the fixed plate 14 to move, the fixed plate 14 moves to drive the positioning hole 15 to move, and then the screw 13 passes through the positioning hole 15, when the fixed plate 14 and the lower funnel 5 are closely attached After the assembly, the operator can fix the fixing plate 14 by tightening the nuts, thereby realizing the fast assembly function of the upper funnel 4 and the lower funnel 5, and reducing the difficulty of assembly.

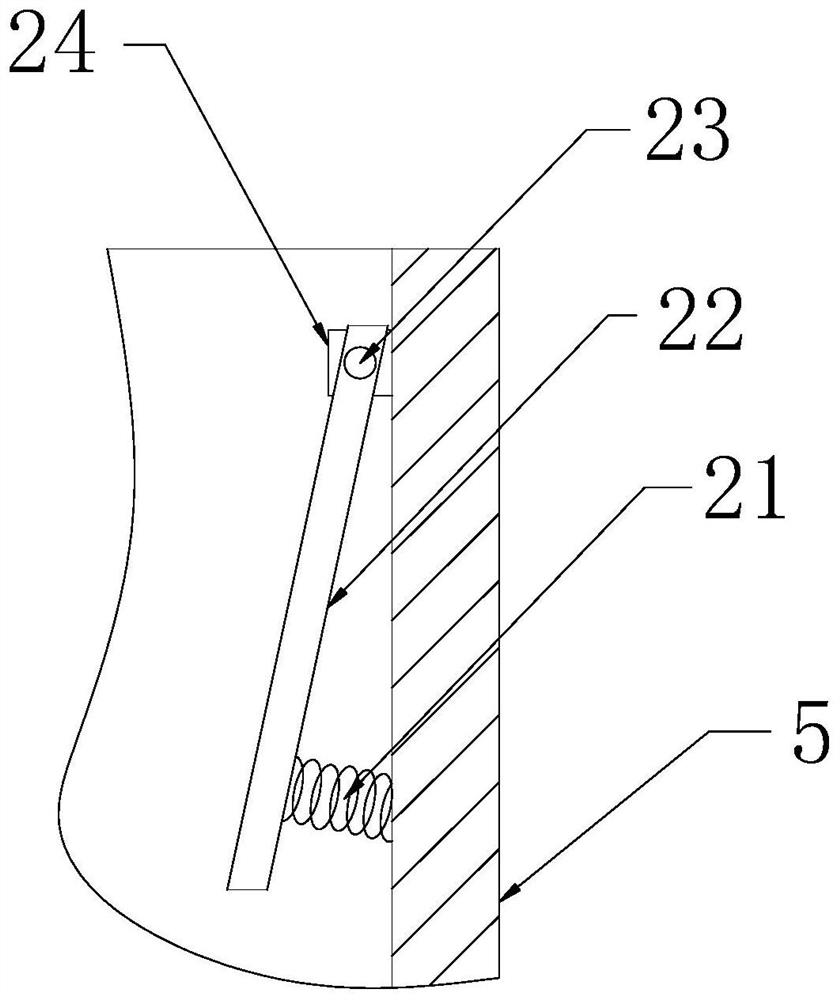

[0027] When the coal material is conveyed into the upper funnel 4, the coal material squeezes the wear-resistant plate 22, and the wear-resistant plate 22 rotates in the bracket 24 through the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com