Furniture production workshop logistics information monitoring system and method

A technology for production workshop and logistics information, applied in the direction of sensing record carriers, resources, instruments, etc., can solve problems such as unfavorable information management, difficulty in realizing system connection, delaying production schedule, etc., to reduce production costs, shorten production cycles, and improve The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

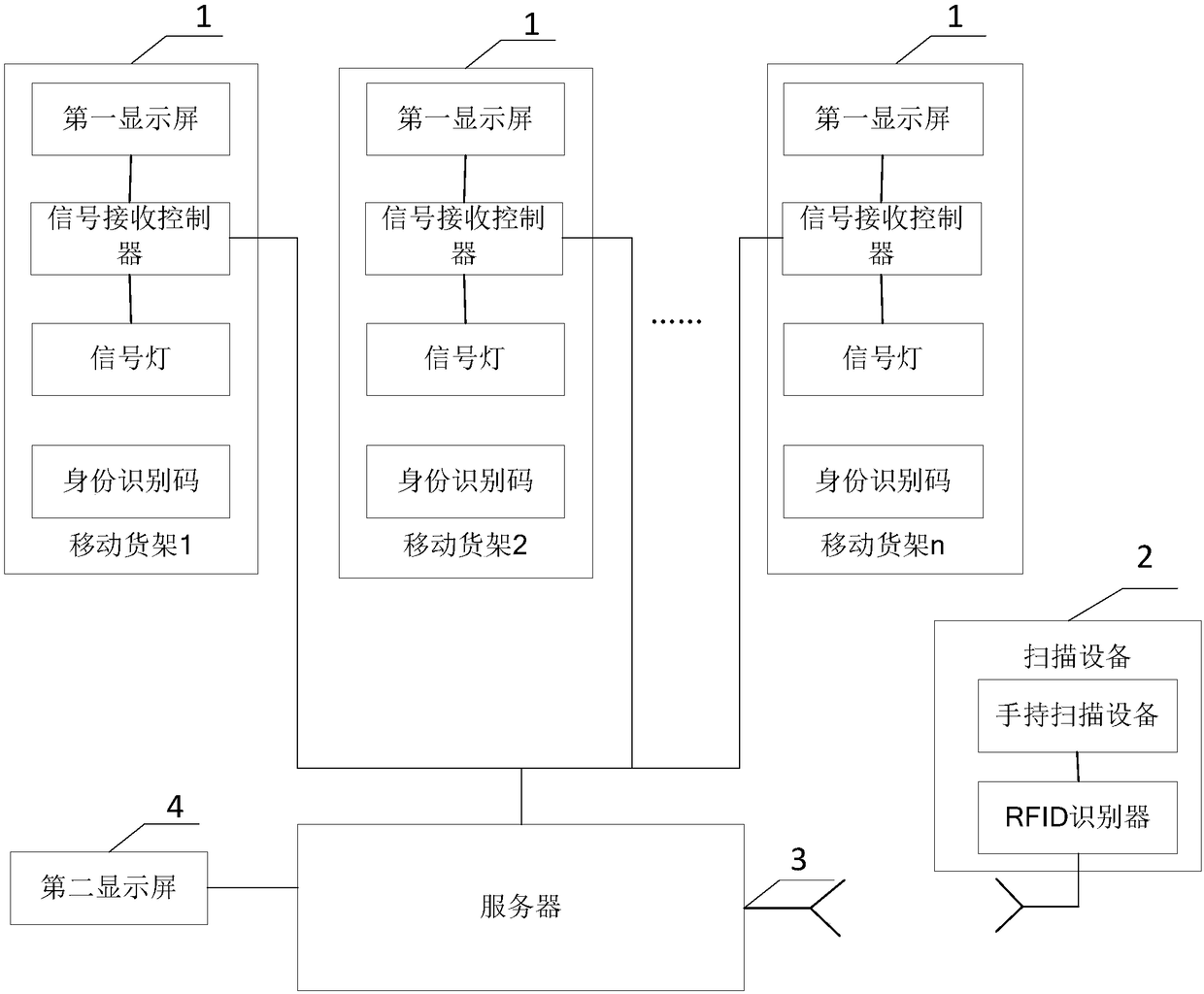

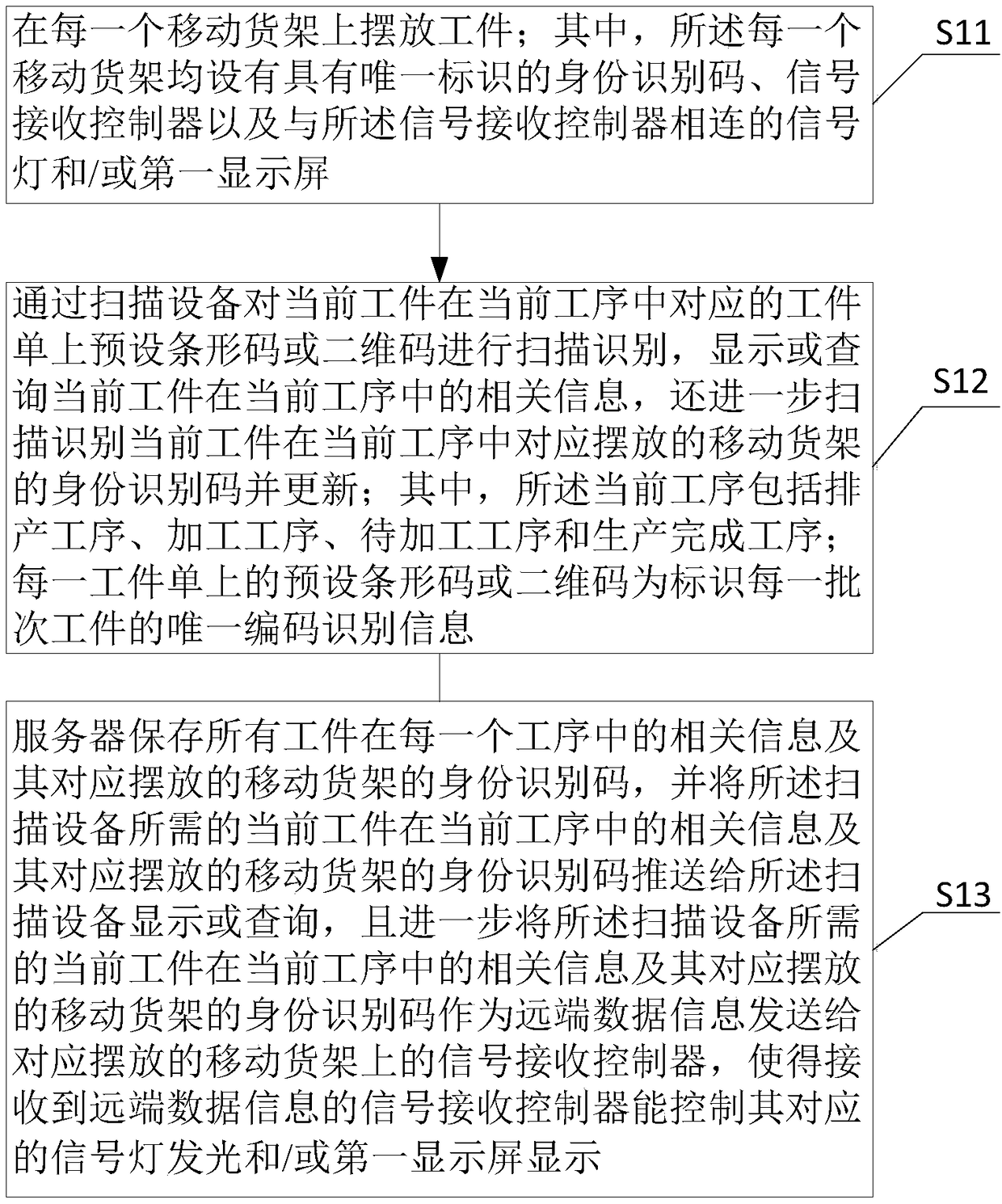

[0026] Such as figure 1 As shown, in an embodiment of the present invention, a logistics information monitoring system for a furniture production workshop is proposed, including:

[0027] Multiple mobile shelves 1, each mobile shelf 1 is provided with a unique identification code, a signal receiving controller, a signal light and / or a first display screen connected to the signal receiving controller, and each mobile shelf uses To place the workpiece, and receive remote data information through the respective corresponding signal receiving controller to control the corresponding signal lamp to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com