Fixing method of coke pot lining plates

A fixing method and lining technology, which are used in the cooling of coke, coke oven, petroleum industry, etc., can solve the problems of difficult installation and fixing of coke tanks, poor stability of linings, inconvenient fixing and installation, etc., so as to reduce installation costs and lower costs. , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

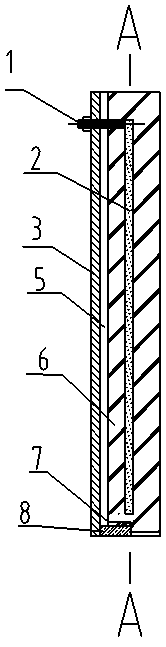

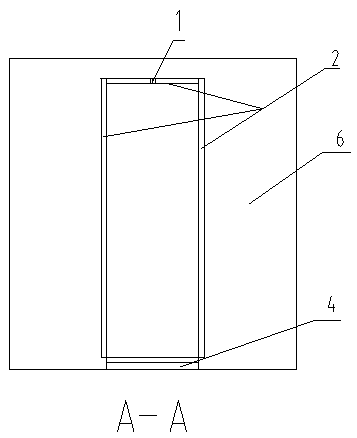

[0026] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of the fixed structure of the coke tank liner of the embodiment of the present invention, figure 2 for figure 1 Sectional view of A-A in Fig. The method for fixing the coke tank liner of the present invention, the liner is prefabricated by refractory castables and then baked. It is a rectangular block with a length of 539mm, a width of 500mm, and a thickness of 65mm. A φ12mm stainless steel is arranged on each longitudinal side of the interior. As the liner keel 2, a through hole for passing through the bolt 1 is provided between two keels on the longitudinal top of the block, and the distance between the two keels is 160 mm. The material of the stainless steel lining board keel is stainless steel 0Cr25Ni20. The longitudinal bottom of the block is provided with a groove 4, and each lining plate weighs 40-50kg, and its heavy-duty working temperature is 950 to 1050°C. The fixing method of the coke ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com