Spunlace non-woven curtain fabric and production method thereof

A production method and non-woven technology, which is applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of low weight and light fastness, and achieve the effects of saving raw materials and energy, stiff hand feeling and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

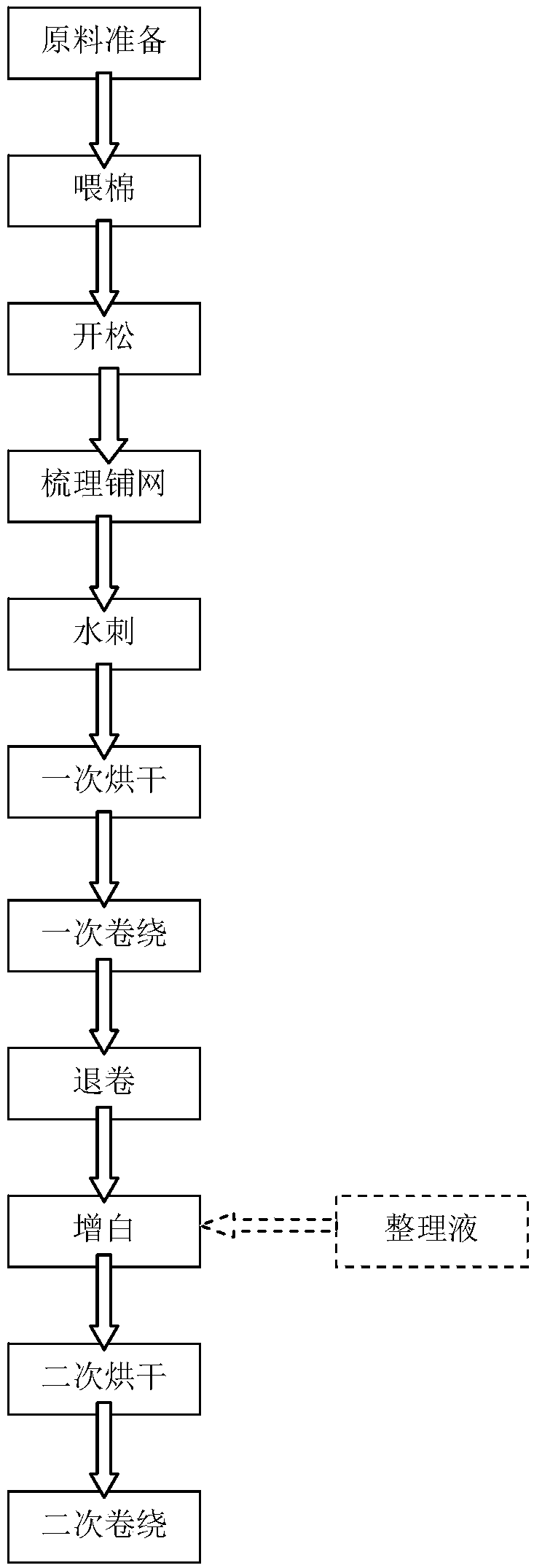

[0027] Such as figure 1 As shown, the production method of the spunlace nonwoven curtain cloth described in this embodiment includes the following steps: feeding the polyester fiber, opening, carding, spunlace, drying once, winding once, unwinding, increasing Whitening, secondary drying, and secondary winding (because it is off-line, drying and winding need to be done twice) to obtain the spunlace nonwoven curtain fabric.

[0028] (1) Raw material preparation: Prepare the high-clean polyester fiber for use. The initial quantitative is scheduled to be 40g / m 2 .

[0029] (2) Cotton feeding and loosening: The weighed polyester fiber is transported to the coarse opener by the automatic cotton feeder for opening, so that the fiber blocks and large cotton clusters are separated and fully loosened. The coarsely opened polyester fiber enters the large warehouse mixing box, and then enters the fine opener to open the fiber more finely, so that the fiber is as close as possible to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com