Heater, washing machine provided with heater and control method thereof

A technology for heaters and washing machines, which is applied to the control device of washing machines, other washing machines, chemical instruments and methods, etc., and can solve the problems such as the impact on the service life and installability of the outer tub, the reduction of the strength of the outer tub, and the damage of the cleaning device, etc., to achieve Ease of line setup, reduced installation space, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

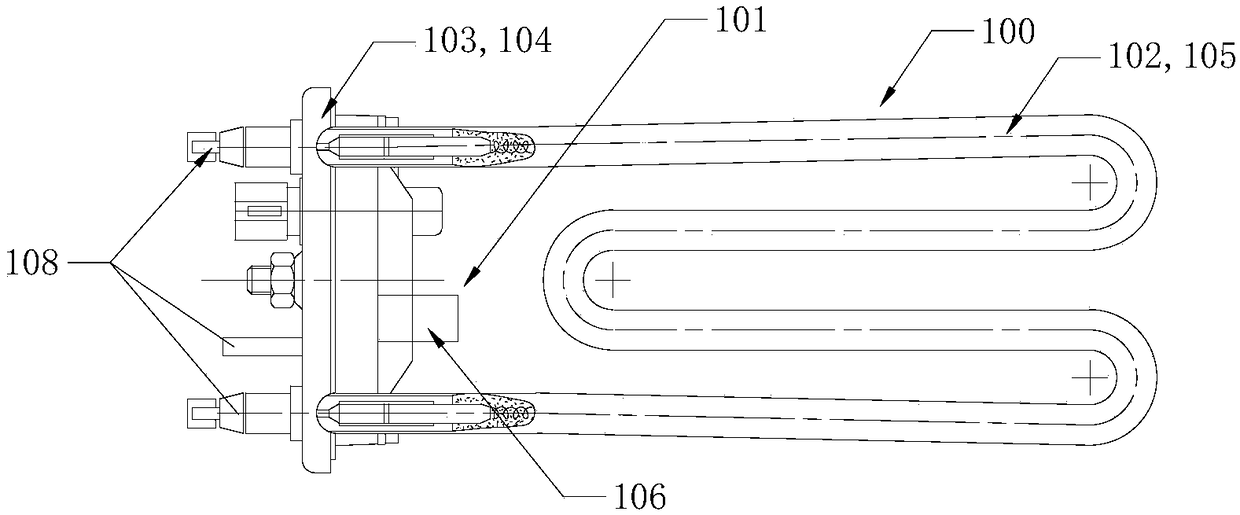

[0037] like Figure 1-2 As shown, a heater includes a heater body 100, an ultrasonic generator 101 is provided on the heater body 100, and the ultrasonic generator 101 is used to remove scale deposited on the heater body 100 when heating water . The ultrasonic generating device 101 is integrated on the heater body 100 to form an integral part. On the one hand, the number of openings on the outer cylinder or other equipment is reduced, and the impact on the strength of the outer cylinder or other equipment is reduced. On the other hand, disassembly The inspection of the heater body 100 and the ultrasonic generator 101 can be realized at one time, and the installation space of the heater body 100 and the ultrasonic generator 101 is greatly reduced.

[0038] In a further solution, the heater body 100 includes a mounting part 103 and a heating part 102 disposed on the mounting part 103 , and the ultrasonic generating device 101 is disposed on the mounting part 103 and / or the heat...

Embodiment 2

[0057] A washing machine with the heater described in Embodiment 1 includes an outer tub, and the heater body 100 is arranged on the outer tub to heat the washing water in the outer tub.

[0058] The washing machine is explained as an example where the washing machine is a drum washing machine.

[0059] The washing machine includes an outer cylinder and an inner cylinder, and the heater is arranged on the lower part of the bottom wall of the outer cylinder to prevent dry burning.

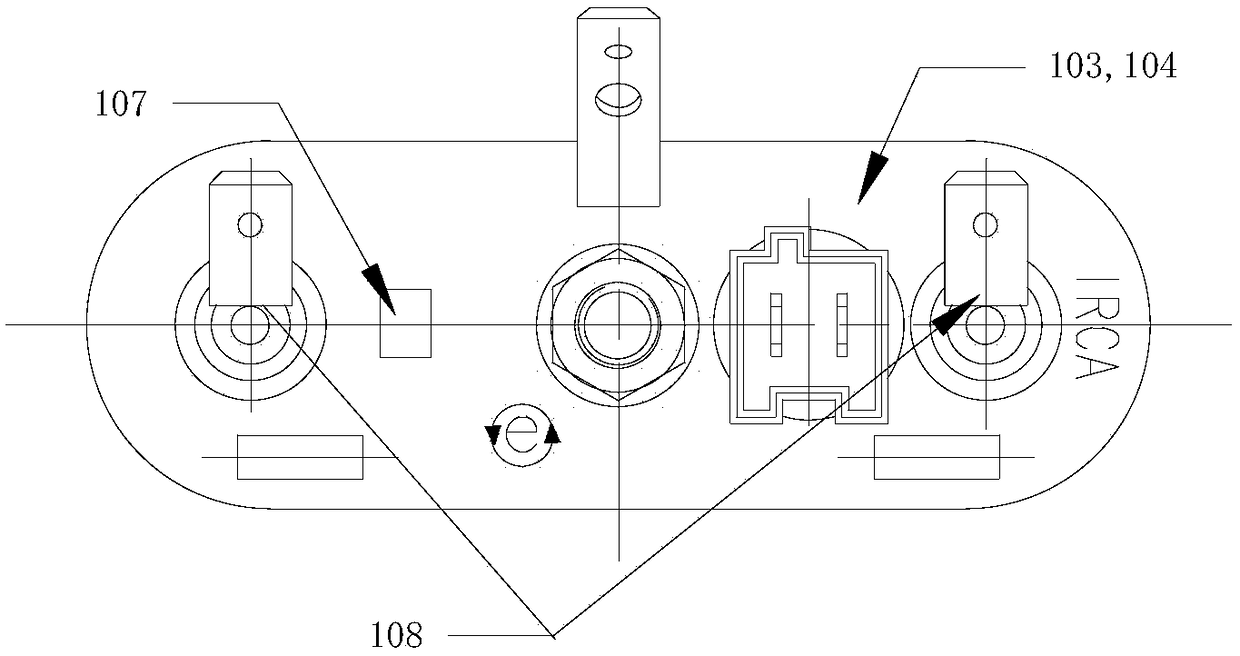

[0060] The heater includes a heating tube 105 and a tube plate 104, and the heating tube 105 is a U-shaped heating tube. The tube plate 104 is elongated and has a major axis. The tube plate 104 is provided with two mounting ports for installing the heating tube 105. The center of the mounting port is longer than the major axis, and the two ends of the heating tube 105 pass through the two openings respectively. And be connected with heating tube 105 connection terminal 108.

[0061] A mounting hol...

Embodiment 3

[0067] This embodiment is the control method of the washing machine in the second embodiment. During the process of heating the washing water by the heater, the washing machine controls the ultrasonic generator 101 to turn on to clean the scale deposited on the heater body 100 .

[0068] In a further solution, the washing machine also includes a temperature detection device for detecting the temperature of the washing water. During the process of heating the washing water by the heater, the washing machine controls the ultrasonic generator 101 to turn on according to the temperature of the washing water detected by the temperature detection device.

[0069] In a further solution, the washing machine calculates the temperature change rate of the washing water according to the temperature of the washing water detected by the temperature detection device, and controls the ultrasonic generator 101 to turn on according to the temperature change rate of the washing water.

[0070] So...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com