Spring and damper integrated shock absorber

An integrated damper technology, applied in the direction of spring/shock absorber, shock absorber, spring, etc., can solve the problems of difficult adjustment of spring, high cost of implementation, complex structure, etc., to achieve increased space and stable shock absorber , The effect of reducing the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

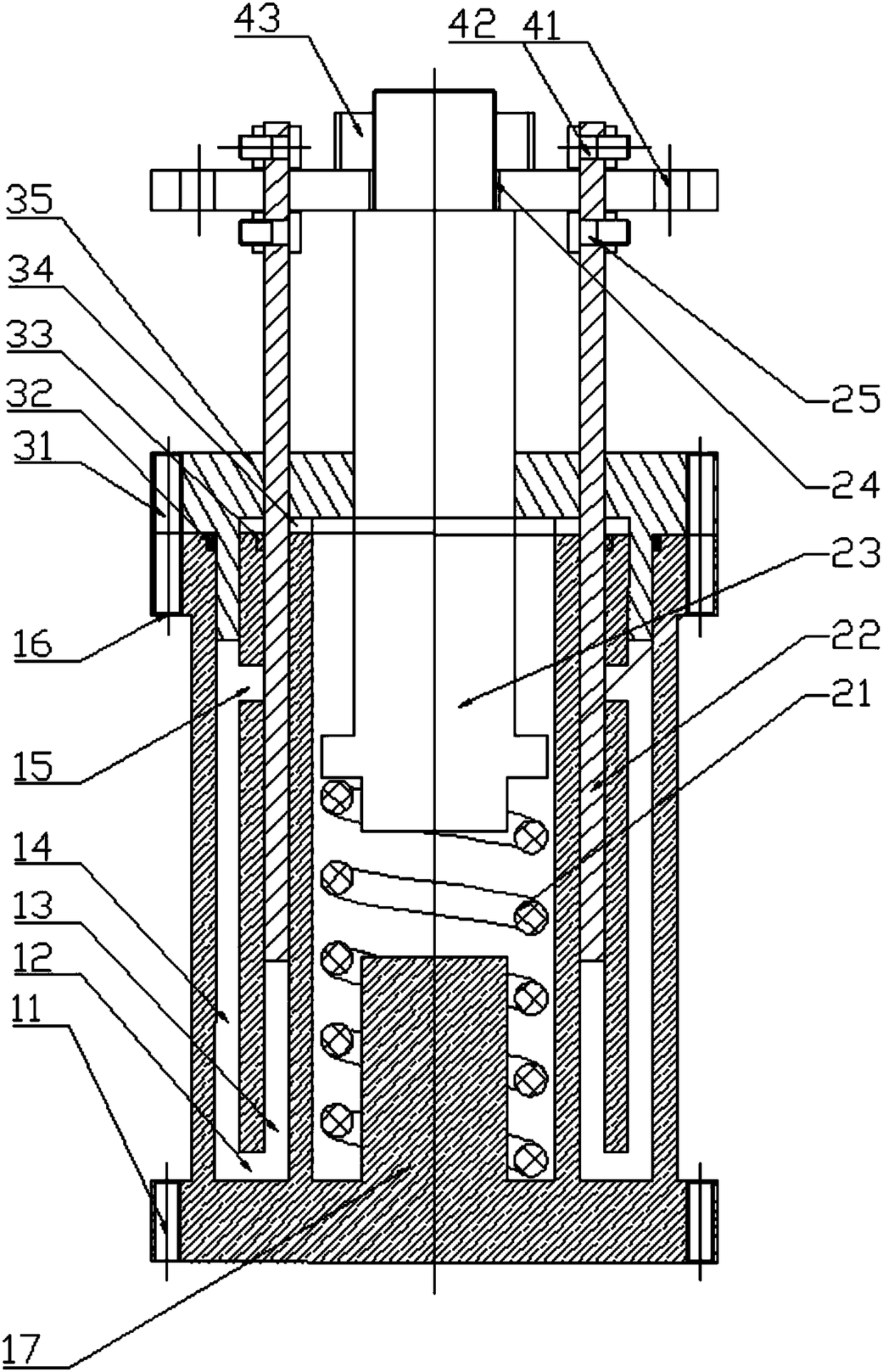

[0024] Embodiment of the present invention: spring and damper integrated shock absorber, as attached Figure 1-5 As shown, it includes four parts: a hydraulic damping device 1, a moving rod 2, a sealing device 3 and a connecting flange 4.

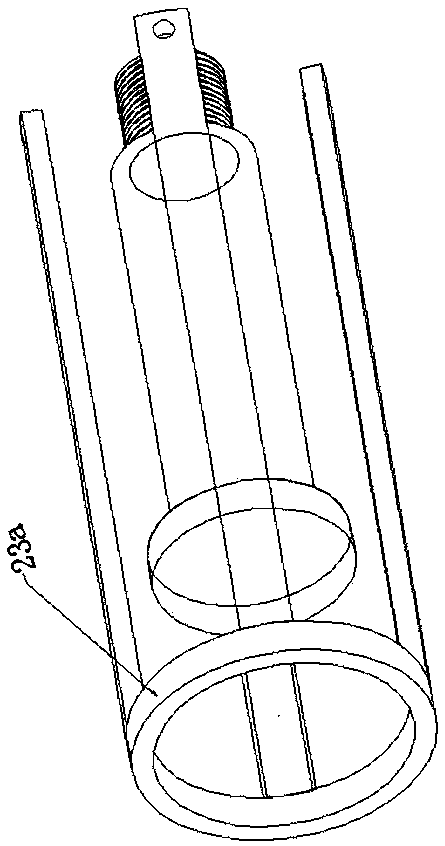

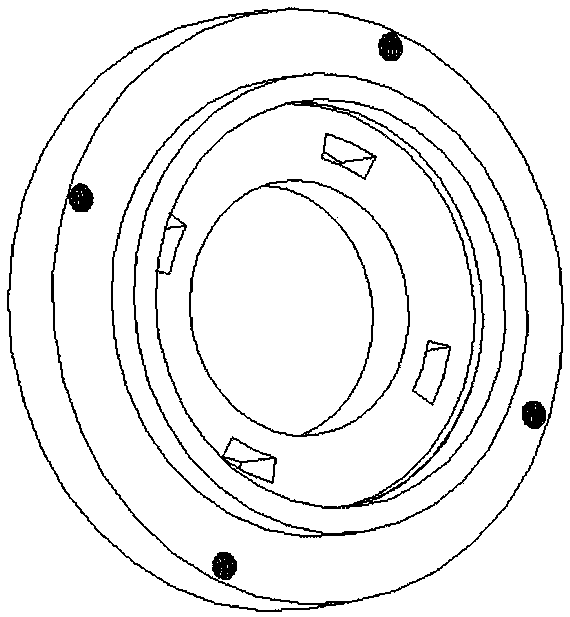

[0025] The hydraulic damping device 1 is an integrated cylindrical chamber composed of a lower threaded hole 11, an upper threaded hole 16, a lower throttle hole 12, an upper throttle hole 15, a right hydraulic chamber 13, a left hydraulic chamber 14, and a spring guide block 17; The moving rod 2 includes a spring 21, a No. 1 rod 22, a No. 2 rod 23, a threaded rod 24, and a through hole 25; the sealing device 3 is sealed by a threaded hole 31, a left hydraulic chamber sealing ring 32, and a right hydraulic chamber. Ring 33, moving rod sealing ring 34, and upper cover plate 35; the connecting flange 4 is composed of a vibration source connecting hole 41, a No. 1 rod fixing hole 42 and a threaded cap 43.

[0026] The hydraulic damping device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com