Lip-shaped mechanical seal device

A mechanical sealing device and lip-shaped technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of service life not meeting customer requirements, damage to the structure of the sealing ring, thermal deformation of the seal, etc., and achieve frictional heat energy Reduce, improve sealing performance, reduce the effect of frictional heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

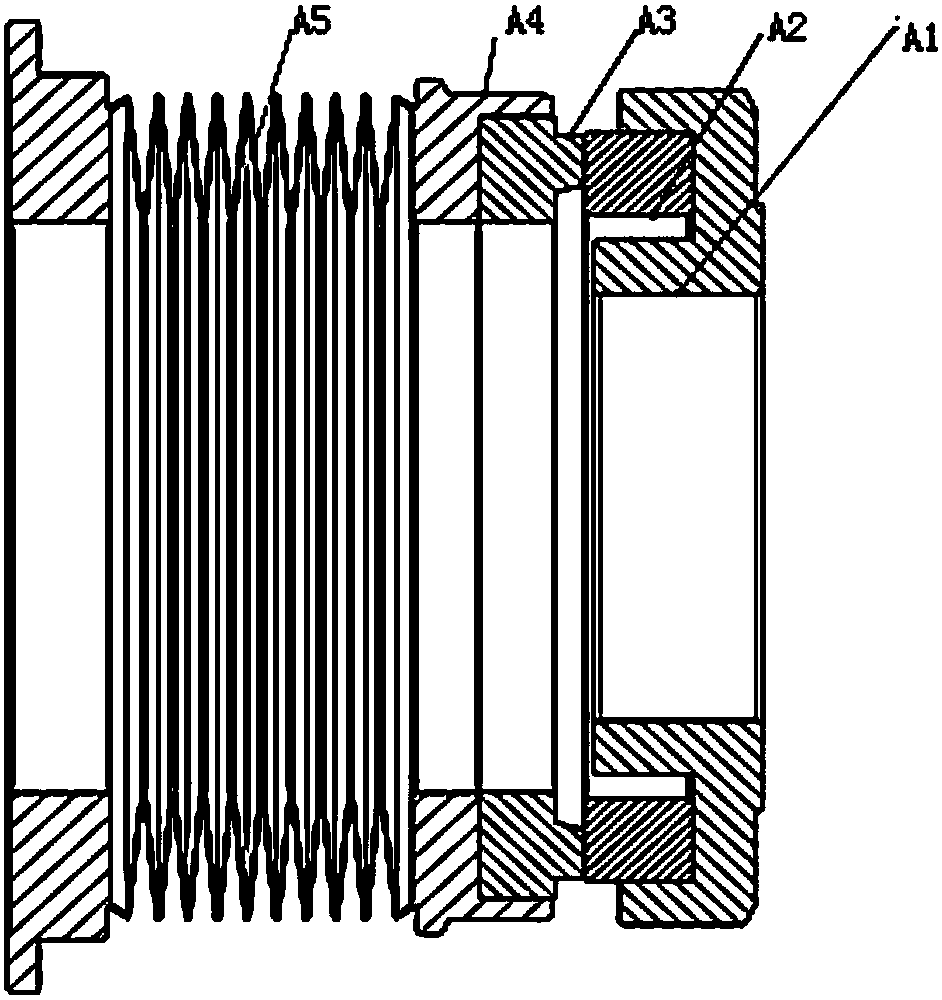

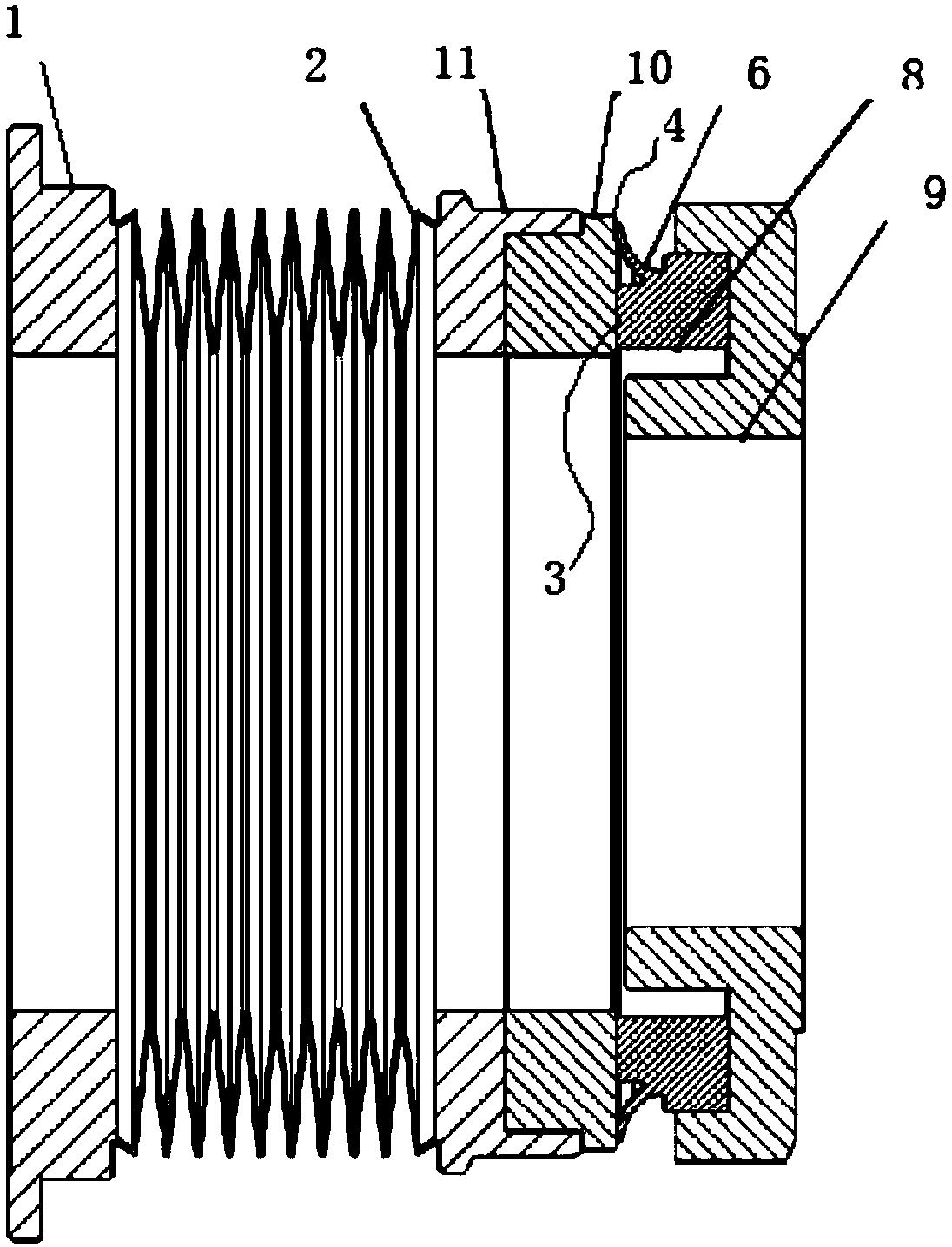

[0053] Embodiment 1: In this embodiment, as Figure 1 to Figure 3 As shown, the end surface of the movable ring has an end surface sealing lip, and the convex surface of the end surface sealing lip abuts against the end surface of the static ring to form the lip-shaped end surface seal.

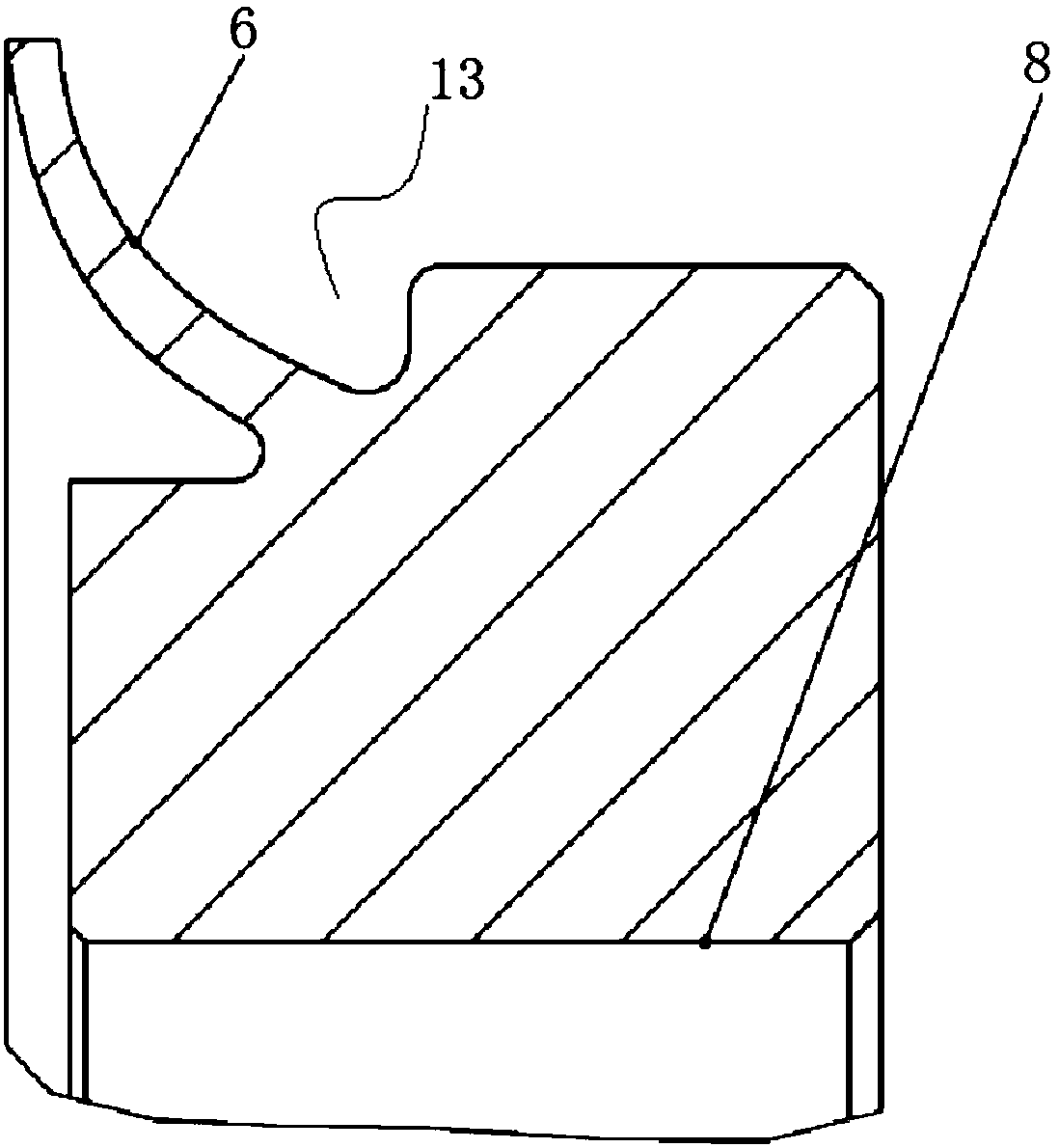

[0054] Such as image 3 As shown, the convex surface of the end face sealing lip is provided with a plurality of pumping grooves 12 for pressure reduction;

[0055] And / or the convex surface of the outer peripheral surface sealing lip is provided with a plurality of the pumping grooves 12 for pressure reduction.

[0056] The moving ring and the moving ring seat are integrally connected or separated.

[0057] When the static ring has an end face sealing lip or / and an outer peripheral face sealing lip, the static ring is a PTFE ring; the end face sealing lip or / and the outer peripheral face sealing lip are integrally connected with the static ring;

[0058] When the moving ring has an end face sealing li...

Example Embodiment

[0061] Embodiment 2: A lip-shaped mechanical seal device, the structure is similar to embodiment 1, the difference lies in: Figure 4 to Figure 5 As shown, the outer circumferential surface of the movable ring has an outer circumferential surface sealing lip, and the convex surface of the outer circumferential surface sealing lip abuts against the outer circumferential surface of the stationary ring seat to form the lip-shaped outer circumferential surface seal.

Example Embodiment

[0062] Embodiment 3: A lip-shaped mechanical seal device, the structure is similar to the embodiment, the difference lies in: Figure 6 to Figure 7 As shown, the end surface of the moving ring has an end surface sealing lip, the convex surface of the end surface sealing lip abuts against the end surface of the static ring to form the lip-shaped end surface seal, and the outer peripheral surface of the moving ring has an outer peripheral surface A sealing lip, the convex surface of the sealing lip of the outer peripheral surface and the outer peripheral surface of the stationary ring seat abut to form the lip-shaped outer peripheral surface seal.

[0063] In this embodiment, the moving ring is split, that is, it is composed of two sub-moving rings, one of which has an end face sealing lip, and the other has an outer peripheral face sealing lip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com