Multi-connection noise reduction control method and multi-connection

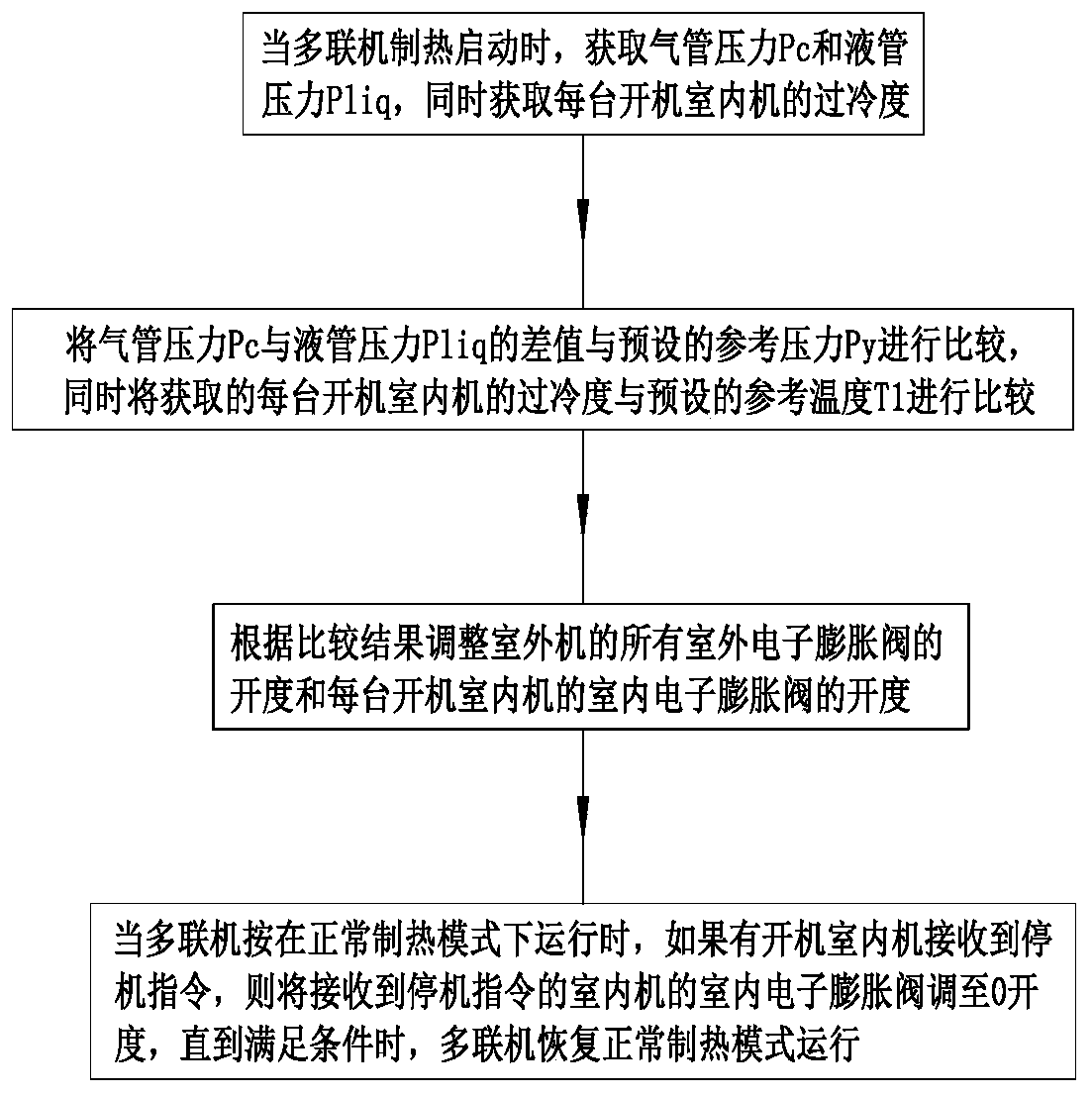

A control method and multi-connection technology, applied in heating and ventilation control systems, heating methods, mechanical equipment, etc., can solve the problems of unstable refrigerant pressure refrigerant vapor-liquid state, high throttling noise, and reduced user comfort. Achieve the effect of stable refrigerant vapor and liquid state, reduce throttling noise, and improve user comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The noise reduction control method of the multi-connection and the multi-connection will be further described in detail below in combination with specific implementation modes.

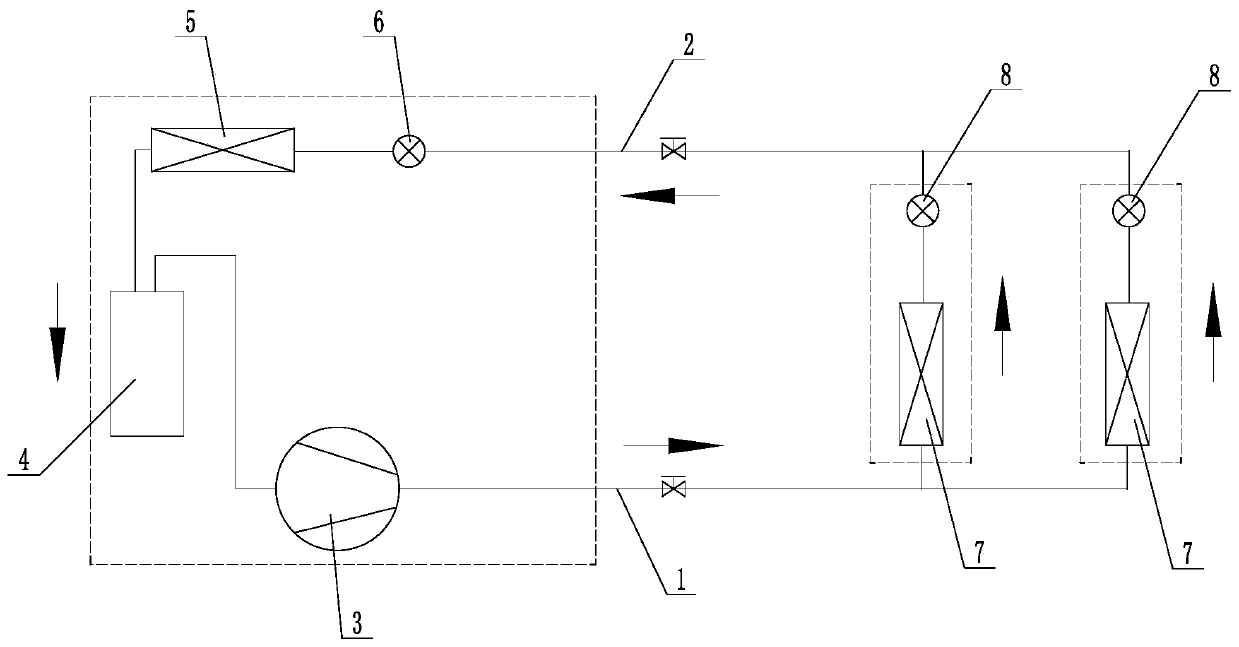

[0040] Such as figure 1 As shown, in this specific embodiment, the multi-split unit of the present invention includes an outdoor unit and a plurality of indoor units, and the outdoor unit communicates with the plurality of indoor units through a gas pipe 1 and a liquid pipe 2, and the outdoor unit includes a compressor 3, a liquid storage Tank 4, outdoor heat exchanger 5 and several outdoor electronic expansion valves 6, each indoor unit includes an indoor condenser 7 and indoor electronic expansion valve 8, the pipeline connection structure between the above-mentioned components is the existing conventional technology, so Not to be described in detail here, the multi-connection device of the present invention adopts the following multi-connection device noise reduction control method.

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com