Vehicle high-temperature temperature sensor thermal response test method

A technology of temperature sensor and thermal response test, applied in the field of sensor detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

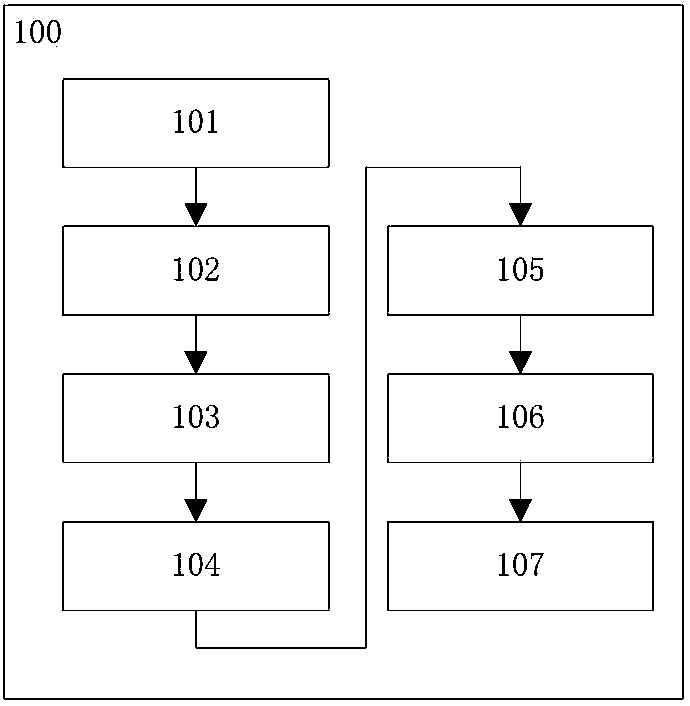

[0038] figure 1A flow chart of a thermal response testing method 100 for a vehicle high-temperature temperature sensor proposed according to the present invention is shown. The method comprises the following steps: setting the constant temperature source to a predetermined temperature T t 101; place the temperature sensor to be tested at room temperature T s Under the environment and continue for a specific time 102; the temperature sensor to be measured is connected with the measuring device and records the current room temperature T s =T O 103; Calculate step temperature T n and timed temperature T x 104; put the sensor to be tested into the constant temperature source and set it as the initial time t 0 105; respectively record each timing time t when the sensor to be tested reaches the timing temperature x 106; Calculate the timing time t x with initial time t 0 interval t x -t 0 107.

[0039] The method for testing the thermal response of a high-temperature tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com