Fine dried noodle packaging machine

A technology of hanging bread and racks, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problem of labor intensity of workers, and achieve the effect of reducing labor intensity and fast packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

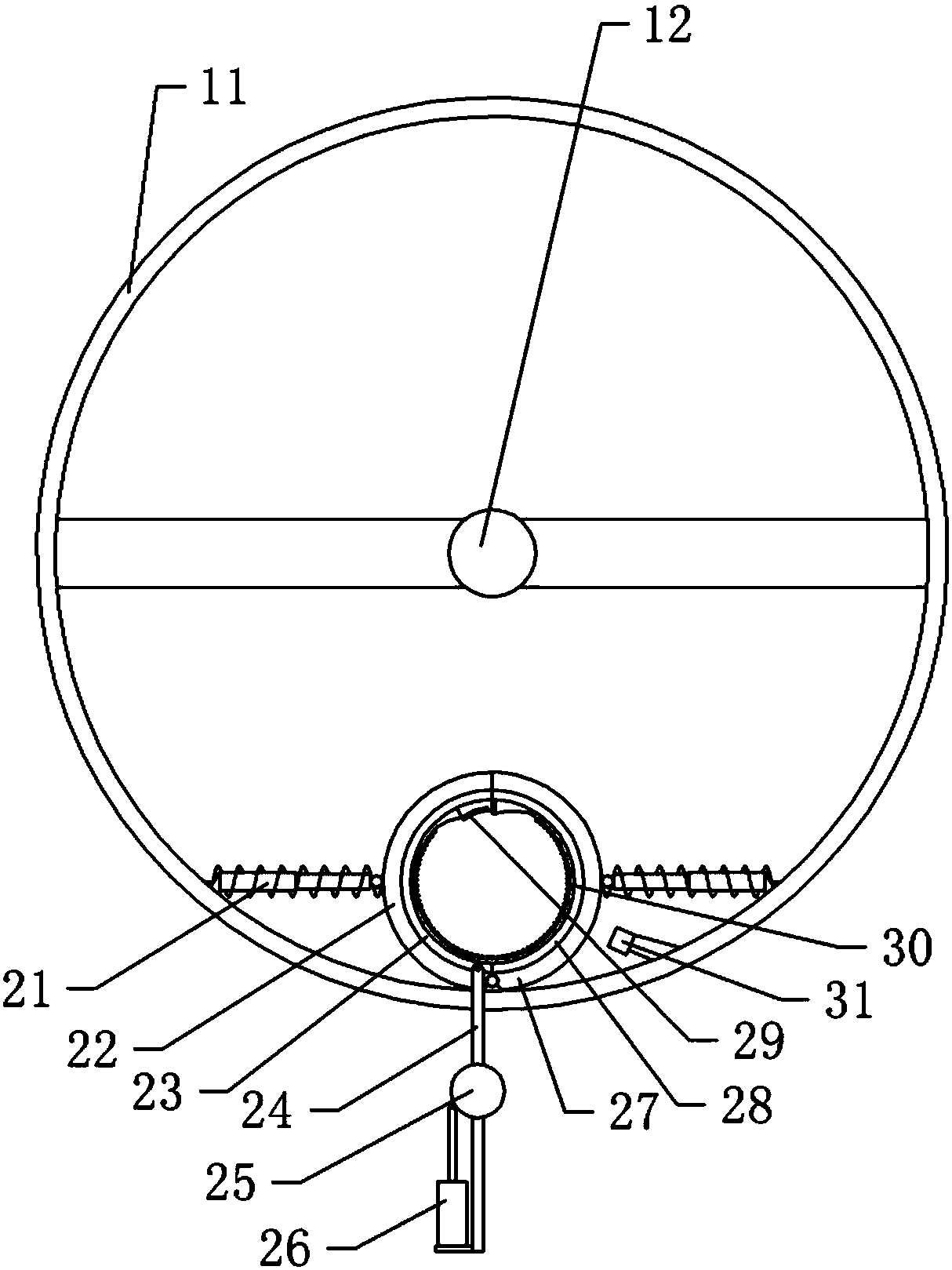

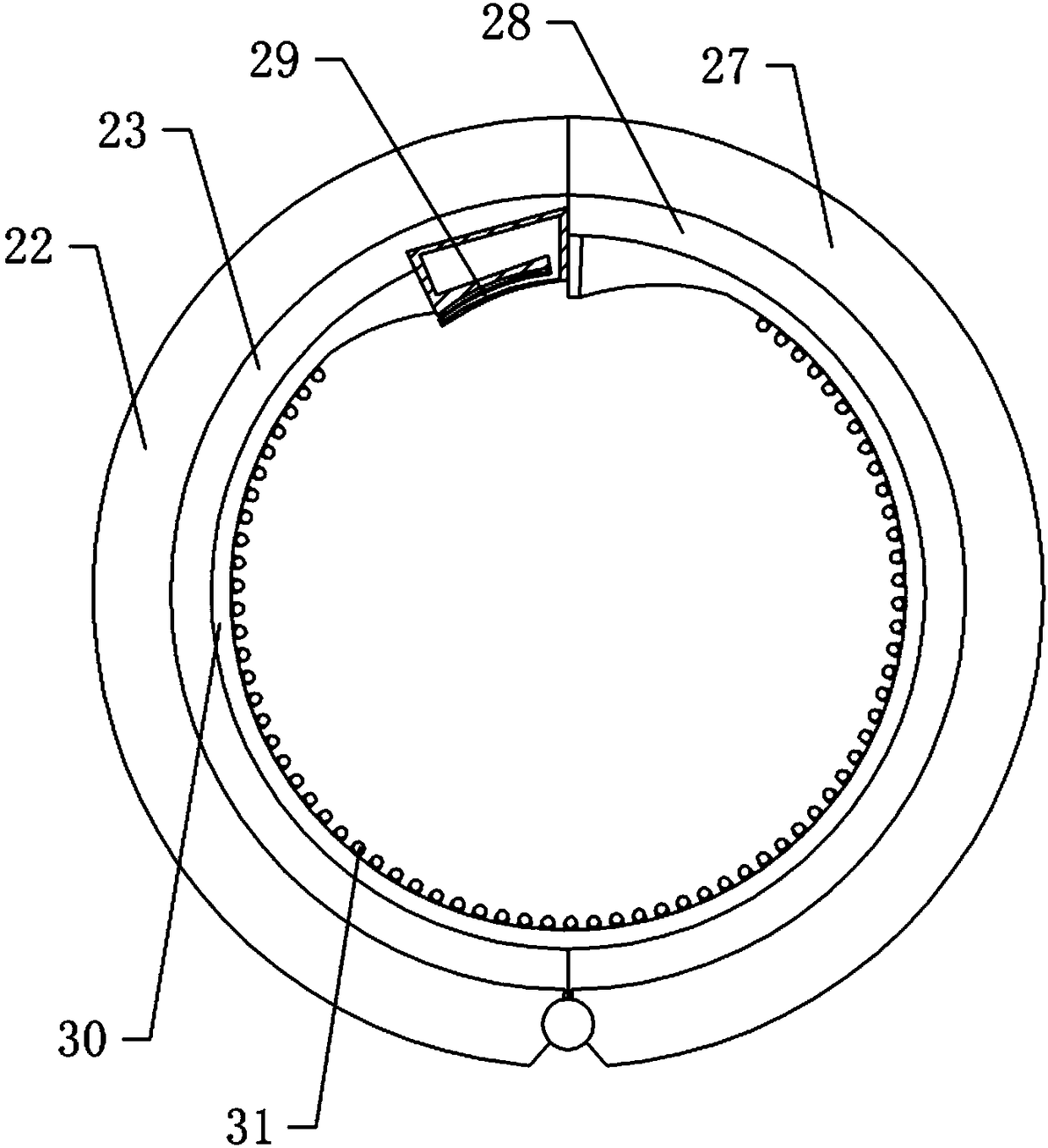

[0016] The reference signs in the drawings of the description include: rotating ring 11, rotating shaft 12, telescopic rod 21, first half splicing cylinder 22, first half supporting cylinder 23, guide rod 24, swing ball 25, cylinder 26, second half splicing cylinder Cylinder 27, second semi-supporting cylinder 28, glue block 29, elastic air bag 30, limit block 31.

[0017] The embodiment is basically as attached figure 1 and figure 2 Shown: a kind of dried noodle packing machine, comprises frame, is connected with rotating ring 11 on the frame, and the outer side of rotating ring 11 is provided with protective cover, and protective cover is connected with frame by bolt. A rotating shaft 12 is rotatably connected to the frame, and the rotating shaft 12 is coaxially arranged with the rotating ring 11, and a connecting rod is welded between the rotating shaft 12 and the rotating ring 11. The coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com